Power take-off wheel

A power wheel and wheel hub technology, applied in the direction of wheels, control devices, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

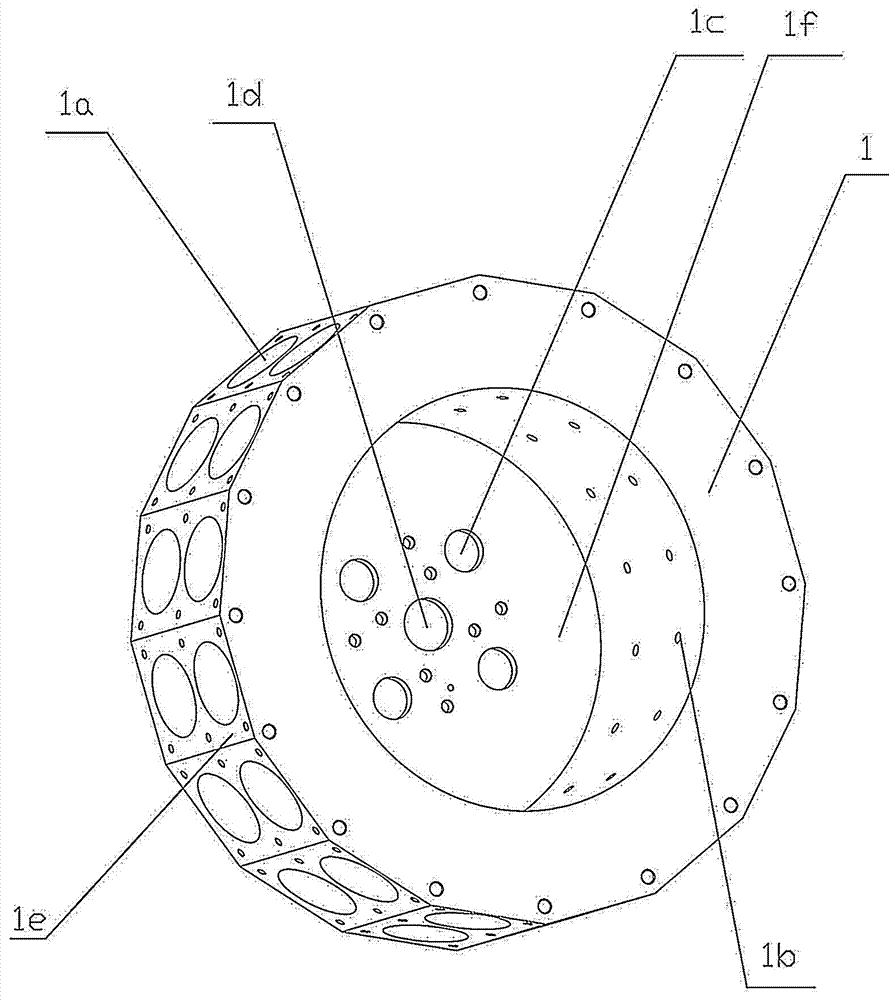

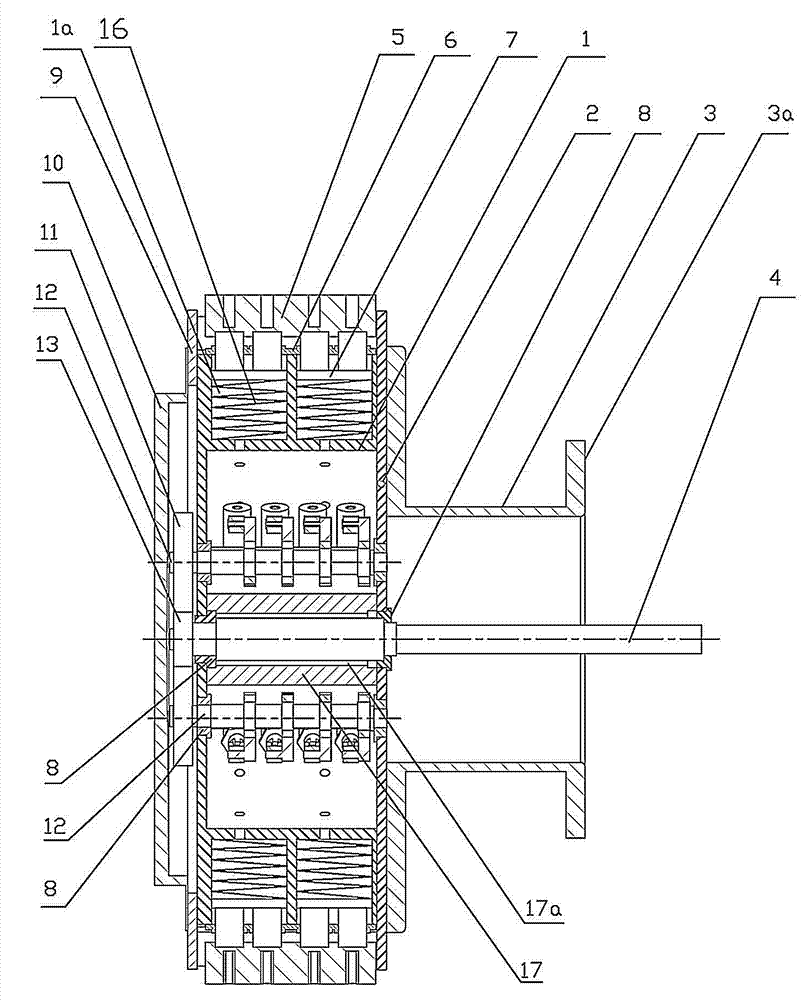

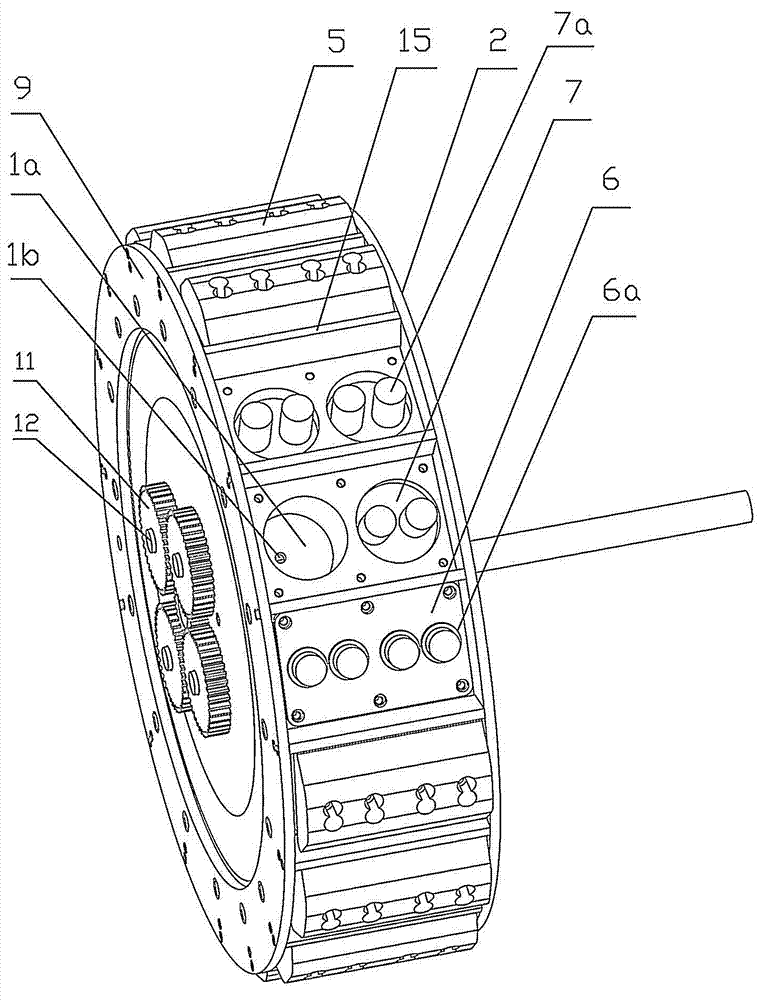

[0021] The power take-off wheel consists of the following components:

[0022] a. Wheel frame

[0023] Such as figure 1 and figure 2 As shown, the wheel frame includes a hub 1, and the center of the hub 1 is provided with a cylindrical cavity 1f. The hub 1 is provided with 16 planar platforms 1e connected end to end, and the planar platforms 1e form a closed polygonal ring. A pair of power cylinders 1a are arranged on each flat platform 1e, and an oil hole 1b is arranged at the bottom of each power cylinder 1a. An output shaft hole 1d coaxial with the hub 1 is provided on the side wall of the cavity 1f, and four rotating shaft holes 1c are evenly distributed on the side wall of the cavity 1f. One side of the hub 1 is connected to the rim 9, and the other side is connected to the rim cover 2, and the rim cover 2 is provided with connecting holes corresponding to the output shaft hole 1d and the rotating shaft hole 1c respectively. Sixteen partitions 15 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com