Logistic vehicle chassis capable of moving along spatial track and movement method

A technology of rail movement and logistics vehicles, which is applied in transportation and packaging, railway car body parts, conveyors, etc., and can solve the problems of low operating speed, weak carrying capacity, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation process is:

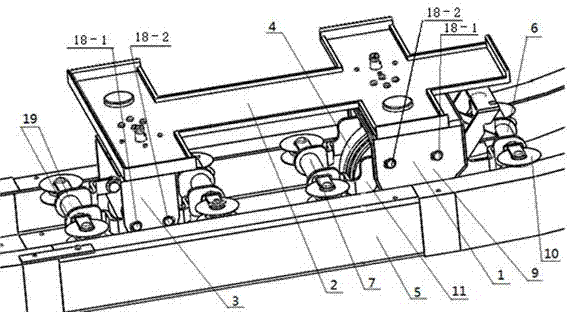

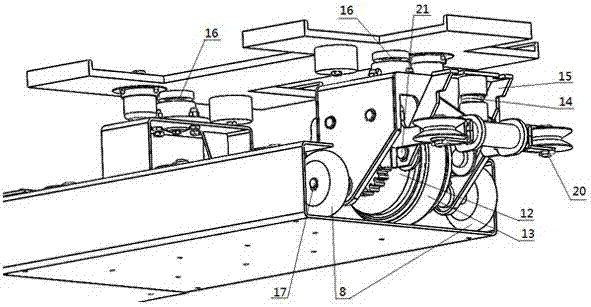

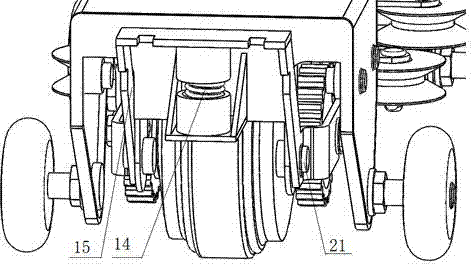

[0018] (1) As shown in the structural diagrams in Fig. 1(a) to Fig. 1(e), the chassis of this rail logistics vehicle is placed in the semi-enclosed space rail 5. The first section of the vehicle body 1 and the third section of the vehicle body 3 are respectively connected at the two ends of the second section of the vehicle body 2 through the turning joint 16 to form a three-section structure. The weight of car body and cargo is borne by load-carrying wheel 8. When the logistics vehicle chassis was above the space rail 5, the load wheel 8 was pressed on such as figure 2 The shown space rail bearing surface 5-1; figure 2 The space track is shown against the top surface 5-3. The first and second section car bodies 1,3 are respectively equipped with front and rear sheave frames 6,7, and the groove of the sheave 10 installed on it is stuck in the opening inner edge of the space track 5, the first section, the third section car T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com