Self-circulation two-stage axial gas-liquid separation cyclone tube

A technology of gas-liquid separation and cyclone tube, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as excessive pressure drop, gas overflow, complex structure, etc., and improve processing efficiency and reduce Effect of pressure drop and enhanced space adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

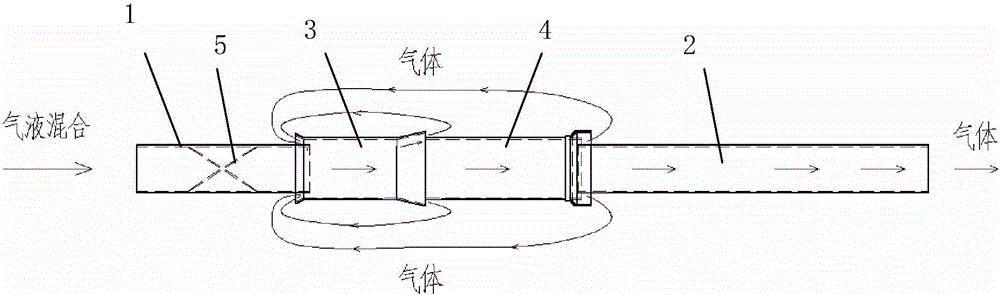

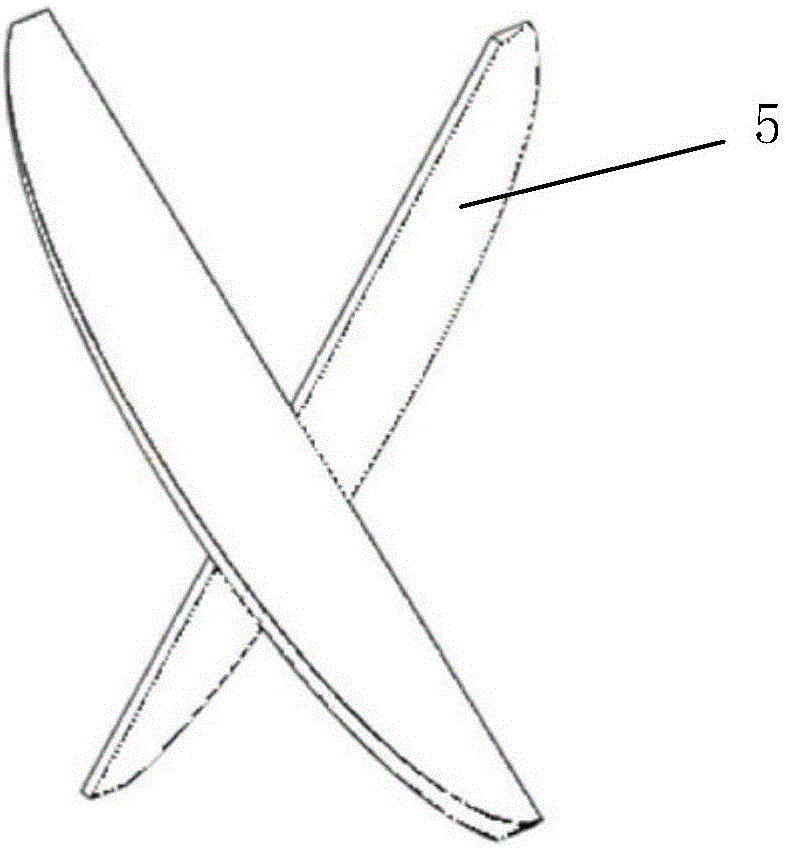

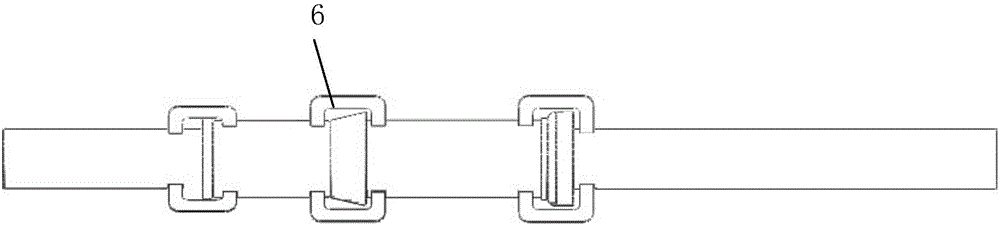

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1-Figure 3 As shown, a self-circulating two-stage axial gas-liquid separation swirl tube includes a first straight pipe section 1, a second straight pipe section 2, a first horn pipe section 3, and a second horn pipe section 4. The first straight pipe section Two fixed intersecting blades 5 are arranged inside to convert the axial flow fluid into rotational motion fluid; the two ends of the first trumpet pipe section are respectively in the shape of a trumpet, and the end of the first straight pipe section is inserted into the first The front end of a trumpet pipe section is fixed together by a U-shaped weldment 6, the front end of the second trumpet pipe section is cylindrical, and the end is trumpet-shaped, and the front end of the second trumpet pipe section is inserted into the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com