Combined cargo bridge for military aviation cargo handling

A technology for cargo handling and military aviation, applied in the direction of equipment for transporting goods, etc., can solve the problems of inability to quickly arrive at the place, limited carrying capacity, unstable center of gravity, etc., to facilitate moving or transshipment, reduce weight and volume, and reduce manufacturing. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

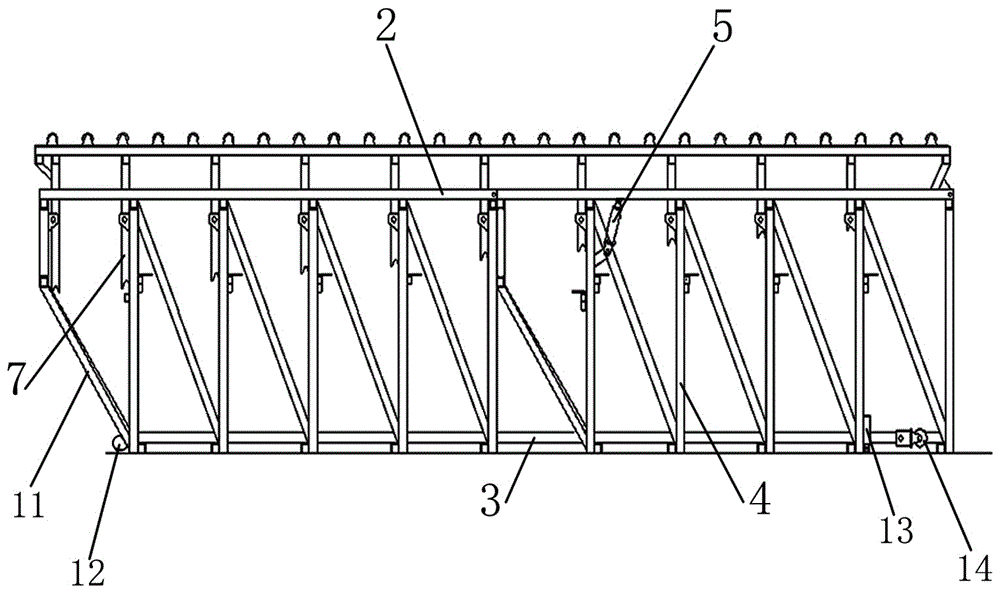

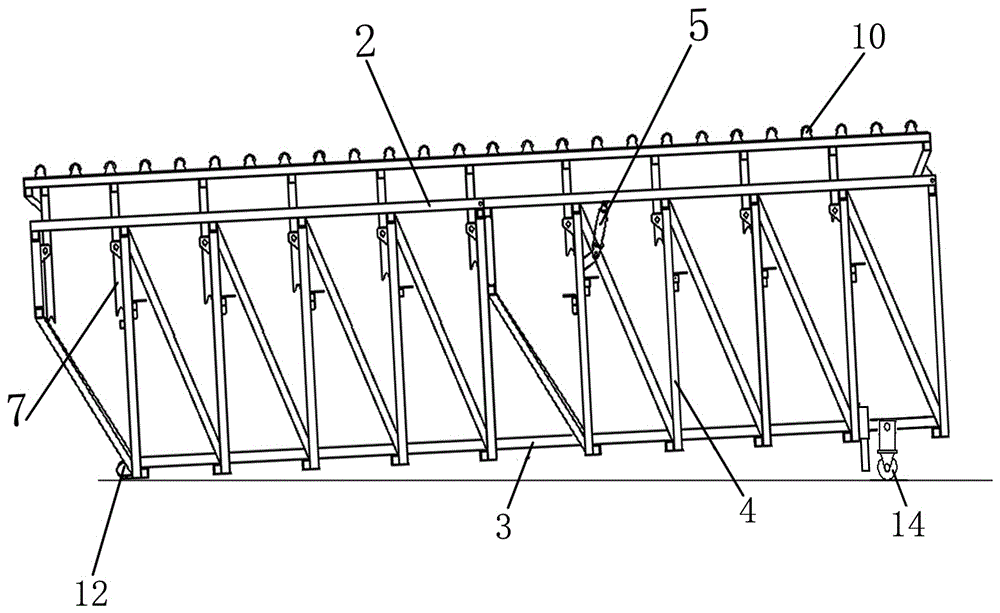

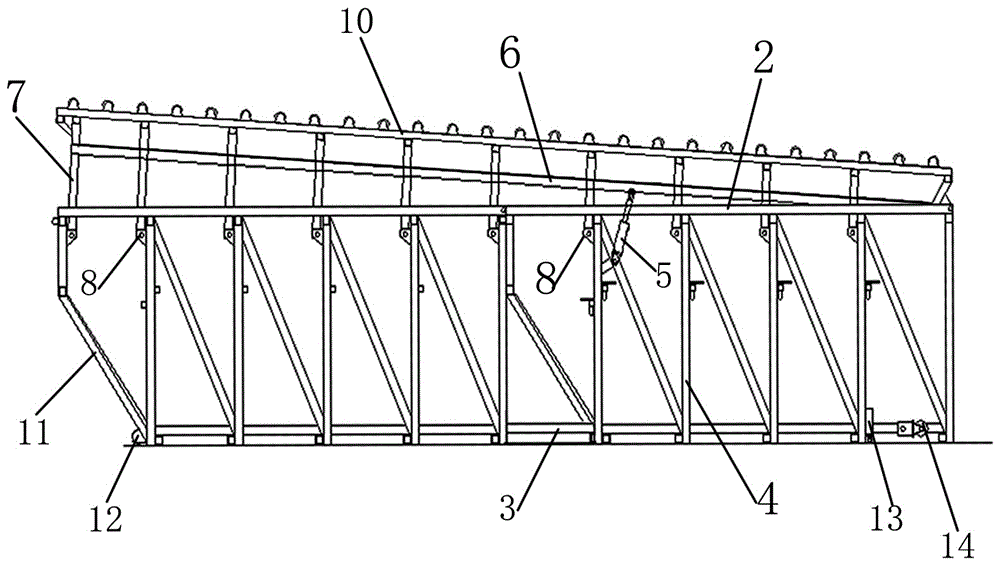

[0018] Now in conjunction with accompanying drawing the present invention is described further, the technical scheme of the present invention is: a kind of military aviation cargo loading and unloading combination cargo bridge, comprises a plurality of support frames and lifting device, the length of each support frame is about 3.5 meters usually, each support frame The connection forms an inclined shape in which the upper surface is close to the ground at the front end and in contact with the bottom plate of the aircraft cargo hold at the rear end, see Figure 4 . In order to increase the bearing capacity and stability of the support frame in the present invention, the size of the bottom part is usually larger than that of the top part, which is approximately trapezoidal in cross-section. The lifting device is arranged on the support frame that is in contact with the bottom plate of the aircraft cargo hold. Two vertical bars 4 are evenly distributed between the top frame 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com