Tapping screw reinforcement structure and method for defected compression member of historic building timber structure roof truss

A technology of self-tapping screws and compression rods, which is applied in building construction, construction, building maintenance, etc., can solve the problems of loss of historical and cultural information, irreversible damage of wooden components, and repairing damage, so as to reduce the construction workload , broad reinforcement application prospects, convenient and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

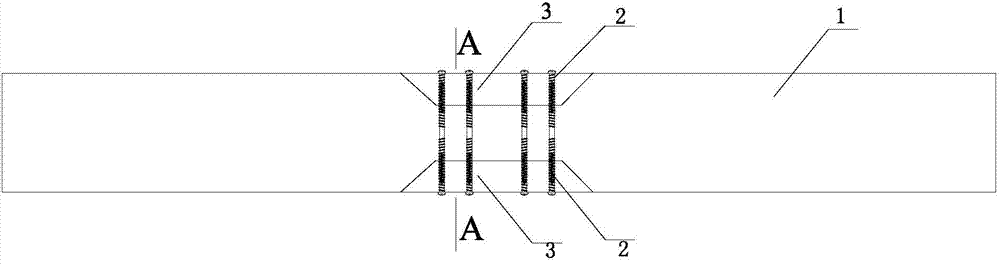

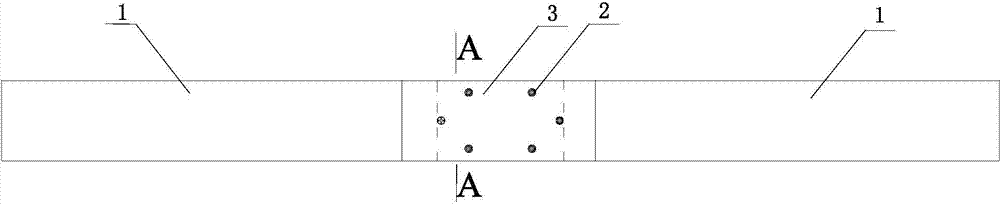

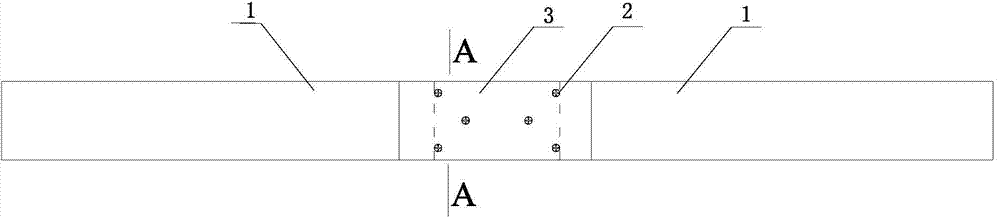

[0027] Such as Figure 1-9 Shown: a self-tapping screw reinforcement structure used for the compression rods of wooden structure roof trusses in ancient buildings, including old wood 1, new filling wood 3 and self-tapping screws 2, and the old wood 1 is provided with defect digging In addition to structure 4, the shape of defect excavation structure 4 is an inverted trapezoid, and the new filling wood 3 is set in the defect excavation structure 4. 1 are reinforced by self-tapping screws 2;

[0028] The defect excavation structure 4 is excavated on one side of the old wood 1 or symmetrically excavated on both sides of the old wood 1;

[0029] The strength level of the new filling wood 3 is higher than or equal to the strength level of the old wood 1, and the new filling wood 3 is consistent with the old wood 1 along the grain direction.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Anchorage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com