System and method for reducing temperature of cooling water of gas engine through LNG (Liquefied Natural Gas) cold energy

A cooling water temperature, engine cooling technology, applied in the direction of engine cooling, engine components, engine control, etc., can solve the problem of cooling loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

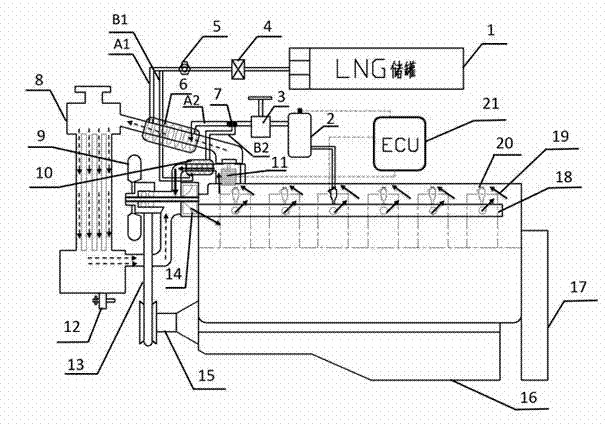

[0028] Such as figure 1 As shown, a system that utilizes LNG cold energy to reduce the cooling water temperature of a natural gas engine includes an LNG supply system, an engine cooling system and an engine body. In the LNG storage tank 1 , the pressure is 1.6 MPa, and the temperature is -162°C. It is necessary to raise the temperature and adjust the pressure of the liquefied natural gas LNG to meet the injection requirements of the natural gas nozzle 20 .

[0029] The liquefied natural gas in the LNG storage tank 1 enters the large circulation heat exchanger 6 through the large circulation LNG supply pipeline A1; enters the small circulation heat exchanger 10 through the small circulation LNG supply pipeline B1. Before LNG enters any heat exchanger, it must pass through the high-pressure cut-off valve 4 and the manual valve 5 to automatically cut off the connection between the LNG storage tank 1 and the LNG supply pipeline when the pipeline pressure increases abnormally.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com