Tangent type low-flow high-lift pump

A high-lift pump and low-flow technology is applied to non-variable pumps, pumps, components of pumping devices for elastic fluids, etc. It can solve problems such as high pressure, increased centrifugal pumps, and system hazards, and achieves The flow head curve is flat and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

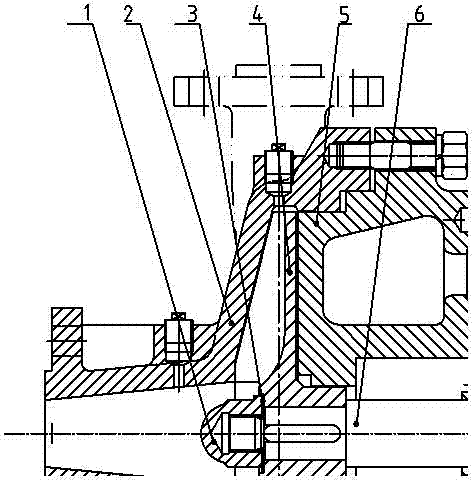

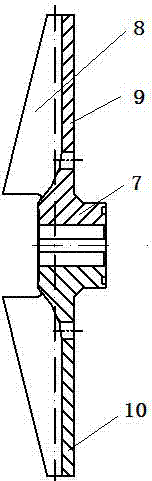

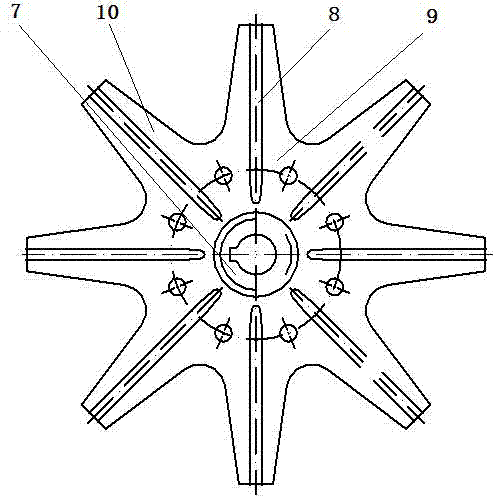

[0012] Below in conjunction with accompanying drawing, the present invention is further described:

[0013] A tangential small-flow high-lift pump, comprising a pump body 2, a pump cover 5, a pump shaft 6, an impeller 4, an impeller nut 1 and a gasket 3, a pump body 2, a pump cover 5, a pump shaft 6, an impeller 4, and an impeller The connection relationship between the nut 1 and the gasket 3 is the same as that of the prior art, so it will not be described in detail here. It is characterized in that the impeller 4 is composed of the impeller hub 7, blades 8, and blade support tooth plates. The blades are straight blades 8, and the impeller There are straight blades 8 in the circumferential array of the hub 7, and the blade supporting tooth plates are tooth-shaped. The blade supporting tooth plates are composed of support rings 9 and plate teeth 10 around the support rings. It is fixedly connected with the impeller hub 7, and the upper end is fixedly connected with the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com