Connecting rod and air compressor with the connecting rod

A technology of connecting rods and connecting parts, which is applied to connecting rods, mechanical equipment, machines/engines, etc., can solve problems such as lack of practicability, mismatched specifications, and easy shaking, etc., achieving remarkable practicability, high applicability, and Work smooth and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

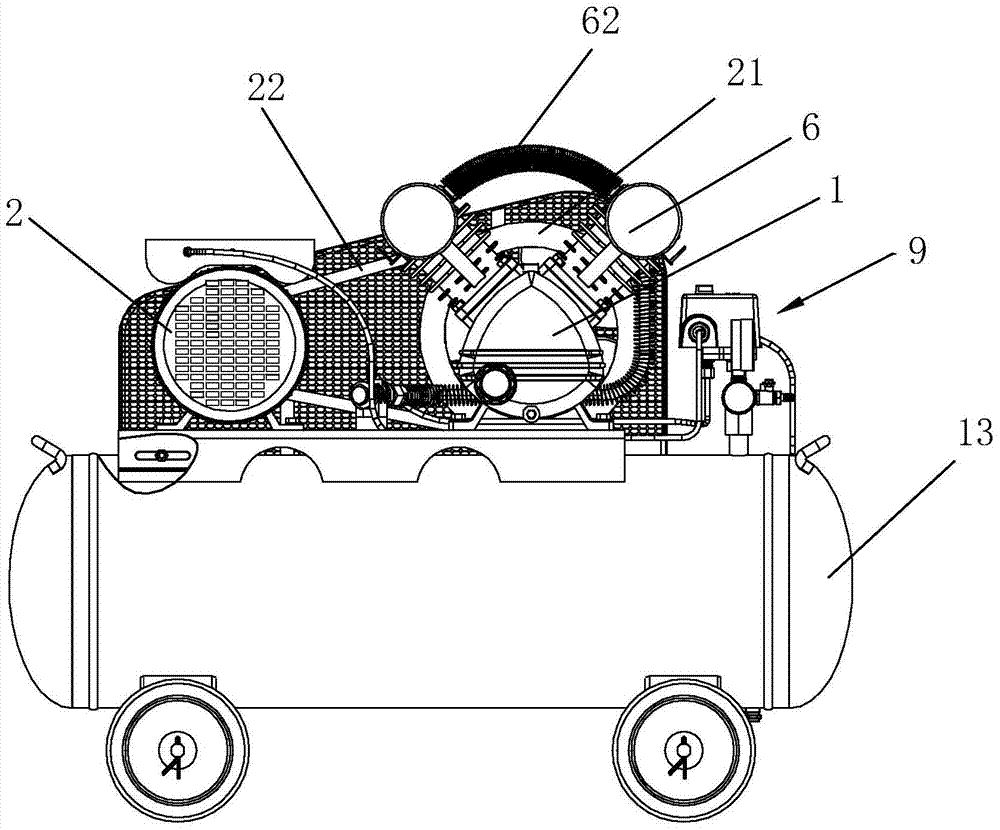

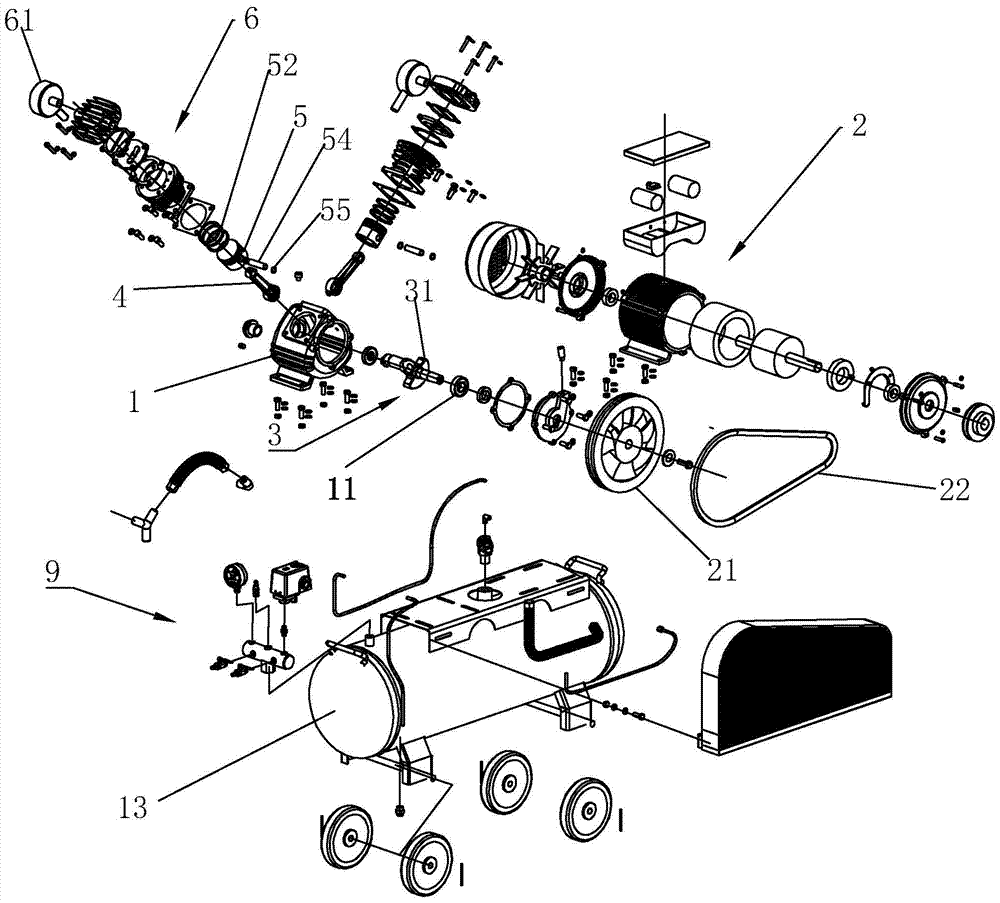

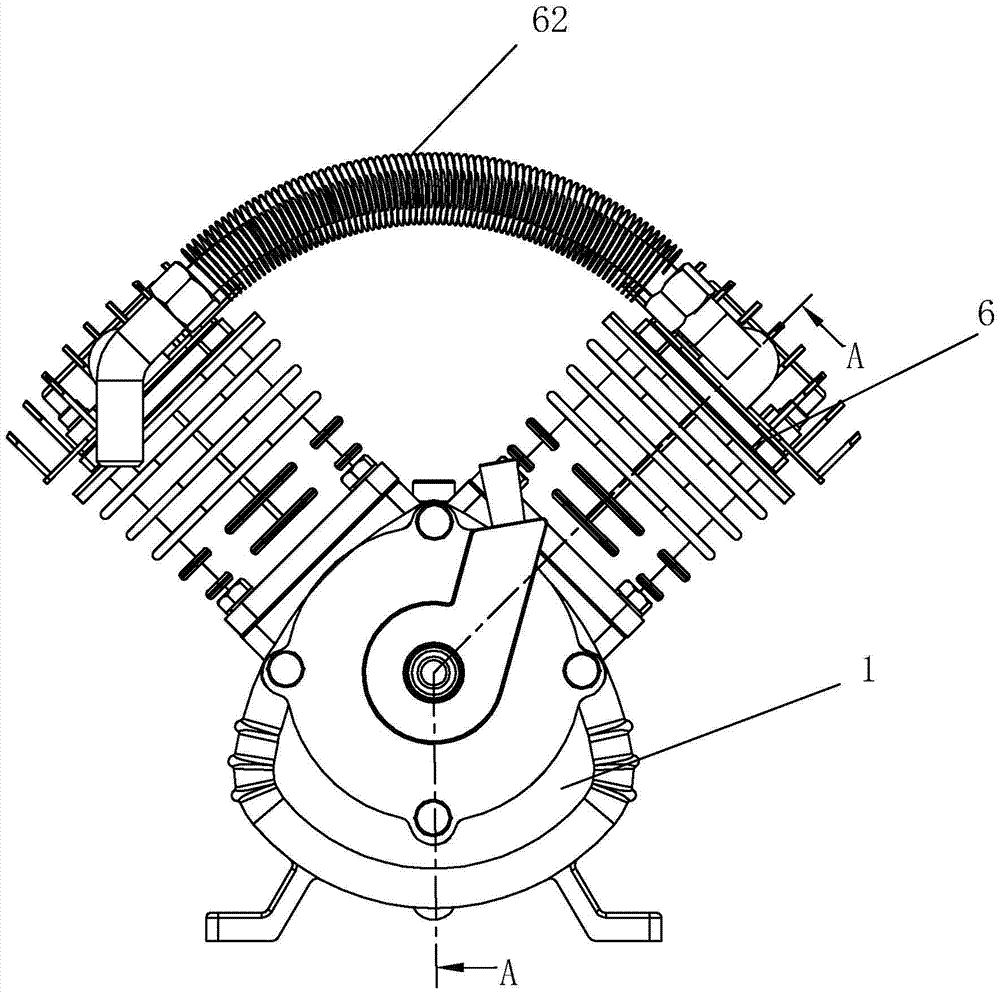

[0036] A connecting rod 4, the connecting rod 4 includes a large end 42, a small end 41 and a connecting portion 43, the connecting portion 43 is connected to the large end 42 and the small end 41 and is integrally arranged, and the large end 42 is provided with an axial thickness adjustment Adjusting mechanism, this adjusting mechanism comprises adjusting ring 7, and the inner wall of adjusting ring 7 is provided with thread, and the surface of big end 42 is provided with the screw thread that axially is arranged, and adjusting ring 7 is threadedly connected with big end 42, so only needs to rotate adjusting ring 7 just The axial movement of the adjustment ring 7 on the big end 42 can be realized, and then the adjustment of the axial thickness can be realized until the adjustment ring 7 conflicts with the crank arm 31. Preferably, both sides of the big end 42 are provided with an adjustment ring 7, In this way, the connecting rod 4 will not have a biased phenomenon, and the wh...

Embodiment 2

[0038]The difference between the connecting rod 4 of this embodiment and that of Embodiment 1 lies in the difference in the limit mechanism. Others are the same as in Embodiment 1. The limit mechanism of this embodiment includes a top block 82, wherein the top block 82 is elliptical and is located on the adjustment ring 7 Between the jack block 82 and the connecting portion 43, a threaded rod 821 is provided on the top end 42, and a threaded hole cooperating with the threaded rod 821 is provided on the big end 42. Since the adjustment of the axial thickness is generally not very large, the adjustment of the top block 82 The length difference between the major axis and the minor axis is not much. The ratio of the preferred major axis to the minor axis length in this embodiment is 1.2:1. By rotating the top block 82 against the adjustment ring 7, the top block 82 is selected to be elliptical, and its edge It is an arc surface, and the transition is smoother when it is rotated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com