A horizontal plate freezer

A technology of freezer and flat plate, which is applied in the direction of cooling machine, lighting and heating equipment, support, etc., which can solve the problems of long time occupation, expansion, low efficiency of freezer, etc., and achieve large production capacity, high efficiency, and small lifting stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

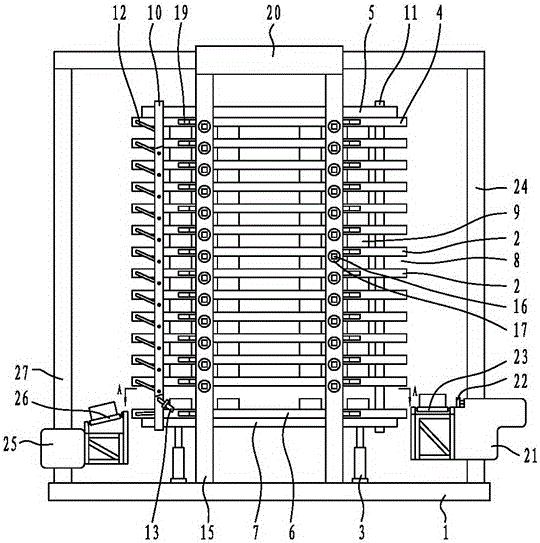

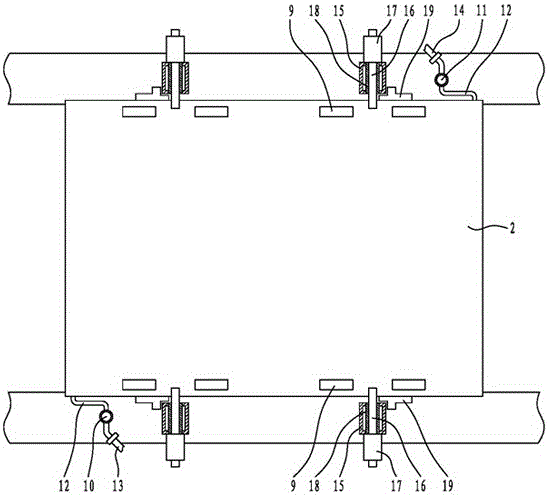

[0017] Embodiment 1: a kind of horizontal plate freezer (see figure 1 , figure 2 ), including the base part 1, the frozen plate 2 stacked above the base part 1 and its lifting device 3, the top plate 5 located above the top frozen plate 4, the bottom plate 7 located below the bottom frozen plate 6, and the space between adjacent frozen plates The frozen layer 8 and the equal-height block 9 on the two edges of the frozen layer 8, the height of the equal-height block 9 is the height of the frozen product, and the refrigerant hoses connected to the refrigerant inlet header 10 and the refrigerant outlet header 11 on the frozen plate 2 12. The refrigerant inlet header 10 and the refrigerant outlet header 11 are respectively connected to the refrigerant outlet pipe 13 and the refrigerant inlet pipe 14 of the refrigerating device. There are bolt posts 15 fixedly connected to the base part 1 on both sides of the stack of freezing plates 2. The bolt posts Corresponding to each frozen...

Embodiment 2

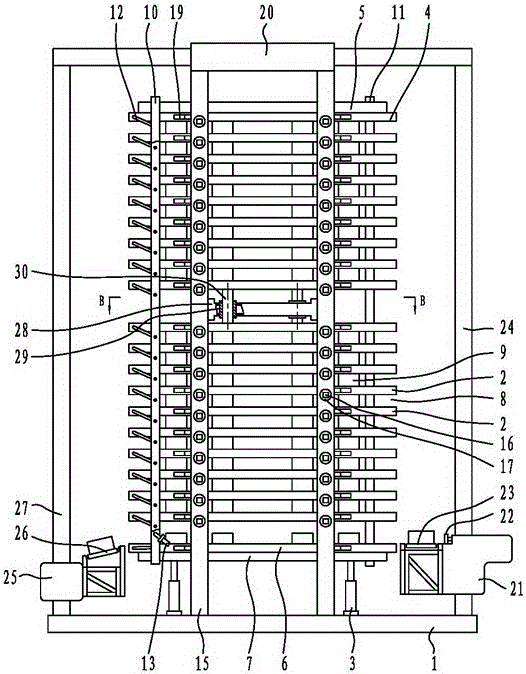

[0019] The difference from Embodiment 1 is: the bolt post 15 has an intermediate connecting frame 28 and the bolt post 15 is fixedly connected (see image 3 , Figure 4 ), the intermediate connecting frame 28 separates the stacked frozen flat plate 2 into upper and lower parts, the intermediate connecting frame 28 has a sliding sleeve 29 and the intermediate connecting frame 28 are fixedly connected, and the sliding sleeve 29 has a supporting sliding column 30, and the supporting sliding column The upper and lower end surfaces of 30 are respectively in contact with the frozen flat plates at the upper and lower ends of the supporting sliding column 30. The frozen flat plate and frozen products above the intermediate connecting frame 28 move up and down with the frozen flat plate below the intermediate connecting frame 28 through the supporting sliding column 30. The connecting frame 28 reduces the deformation of the latch column 15, keeps the relative position of the movable la...

Embodiment 3

[0021] The difference from Embodiments 1 and 2 is that there is a loading beam 31 fixedly connected to the bolt post 15 above the bolt post 15 (see Figure 5 ), the loading cylinder 32 is fixedly connected to the loading beam 31 on the loading beam 31, and the piston rod 33 of the loading cylinder 32 is connected to the top plate 5, which can increase the compressive force of the frozen layers of the upper layers of frozen plates and improve the pressure of the upper layers. Freezing efficiency of frozen products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com