Dehydrator used in cooling tower

A technology for cooling towers and water heaters, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc. Improve water removal efficiency, improve water removal effect, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

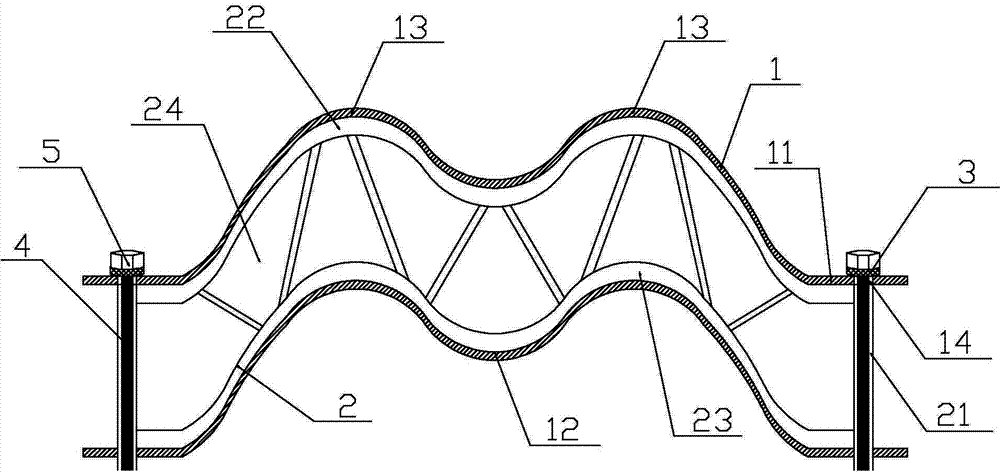

[0015] Such as figure 1 As shown, a water eliminator for a cooling tower is assembled from several water removal sheets 1, brackets 2, positioning rings 3, pull rods 4 and nuts 5. The water removal sheets 1 are corrugated, and the water removal sheets 1 include two Two ends 11, a central trough 12 and two crests 13 located on both sides of the trough 12, the bracket 2 is located between the two water removal sheets 1, the bracket 2 is composed of a column 21, an upper corrugated plate 22, a lower corrugated plate 23 and heat dissipation Holes 24, column 21 is located at both ends of the bracket 2, and the column 21 is a hollow structure, the cooling hole 24 is located between the upper corrugated plate 22 and the lower corrugated plate 23, the tie rod 4 pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com