Preparation method of adsorbent for removing water molecules in hydrogen fluoride gas

A hydrogen fluoride gas and adsorbent technology, applied in the field of adsorbent preparation, can solve the problems of low water removal efficiency, moisture reduction, cumbersome operation, etc., and achieve the effects of high water removal efficiency, increased porosity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

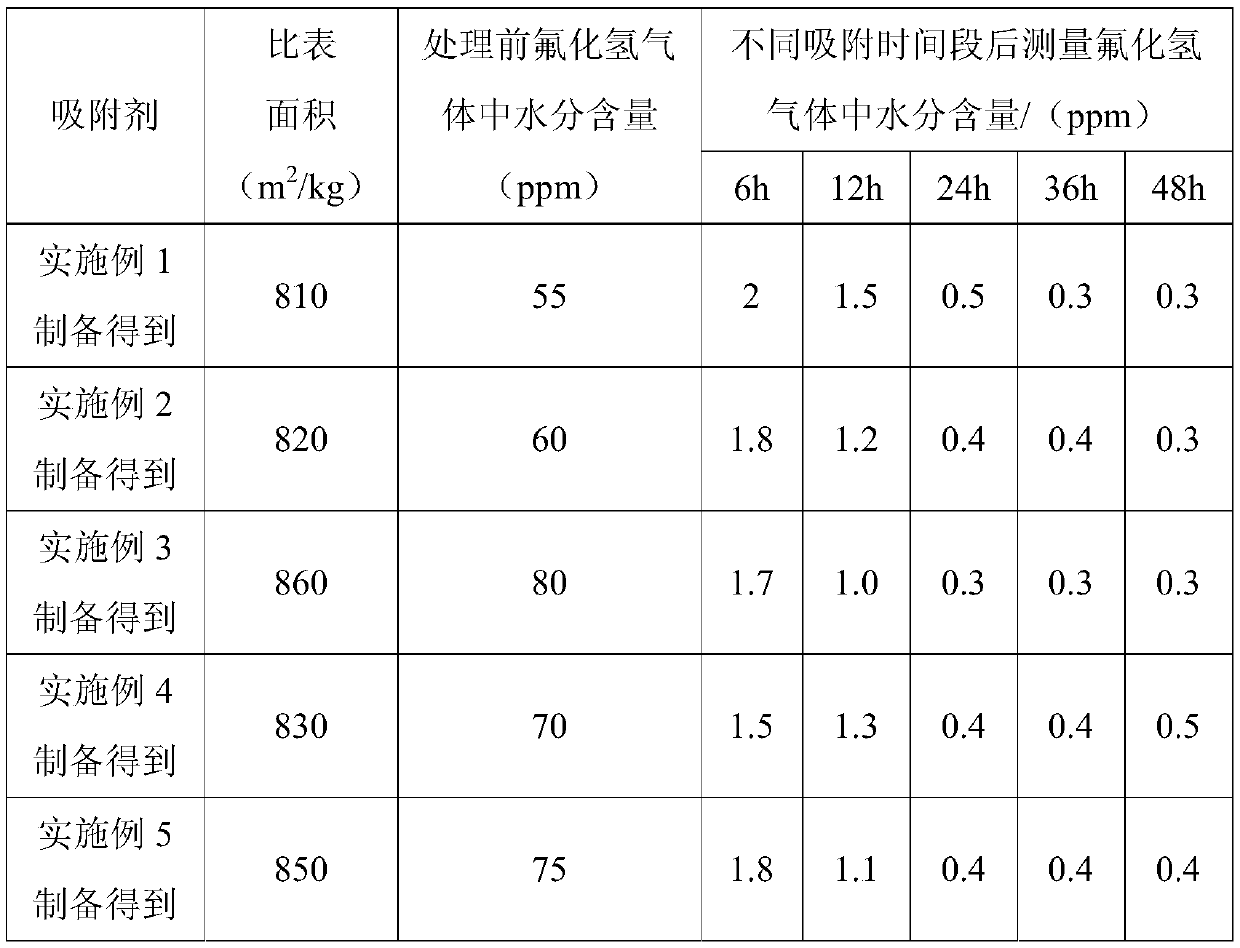

Examples

Embodiment 1

[0037] Example 1: (1) Weigh 0.2 kg of potassium fluoride powder and 5.0 kg of titanium fluoride powder, add 1200 g of ultrapure water and 250 g of sodium bifluoride, mix at a stirring speed of 300 rpm for 20 min, and place at 70 ° C Drying at low temperature for 50 minutes to obtain the fluorine-containing double salt particle molded body;

[0038] (2) sintering the fluorine-containing double salt particle molded body obtained in step (1) at 550° C. for 60 minutes to obtain the sintered fluorine-containing double salt particle molded body;

[0039] (3) The sintered fluorine-containing double salt particle molded body obtained in step (2) is ball milled to obtain an adsorbent product with an average particle diameter of 1200 μm.

Embodiment 2

[0040] Example 2: (1) Weigh 0.5 kg of potassium fluoride powder and 5.5 kg of titanium fluoride powder, add 1300 g of ultrapure water and 150 g of sodium bifluoride, mix at 350 rpm for 15 min, and then mix at 72 ° C Drying at low temperature for 45 minutes to obtain the fluorine-containing double salt particle molded body;

[0041] (2) sintering the fluorine-containing double salt particle molded body obtained in step (1) at 650° C. for 100 min to obtain the sintered fluorine-containing double salt particle molded body;

[0042] (3) The sintered fluorine-containing double salt particle molded body obtained in step (2) is ball milled to obtain an adsorbent product with an average particle diameter of 600 μm.

Embodiment 3

[0043] Example 3: (1) Weigh 0.8 kg of sodium fluoride powder and 4.5 kg of ferric fluoride powder, add 1400 g of ultrapure water and 500 g of potassium bifluoride, mix at a stirring speed of 400 rpm for 10 min, and then mix at 75 ° C Drying under high temperature for 40min to obtain the fluorine-containing double salt particle molded body;

[0044] (2) sintering the fluorine-containing double salt particle molded body obtained in step (1) at 750° C. for 20 minutes to obtain the sintered fluorine-containing double salt particle molded body;

[0045] (3) The sintered fluorine-containing double salt particle molded body obtained in step (2) is ball milled to obtain an adsorbent product with an average particle diameter of 300 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com