Full-automatic centrifugal oil purifier

A centrifugal oil purifier technology, applied in liquid separation, separation methods, auxiliary equipment for liquid separation, etc., can solve the problems of inconvenient centralized management for users, inability of users to determine the cause of failure, failure to display, etc., to improve the degree of automation and service life, realize unattended automatic work, and avoid the effect of mechanical seal wear and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

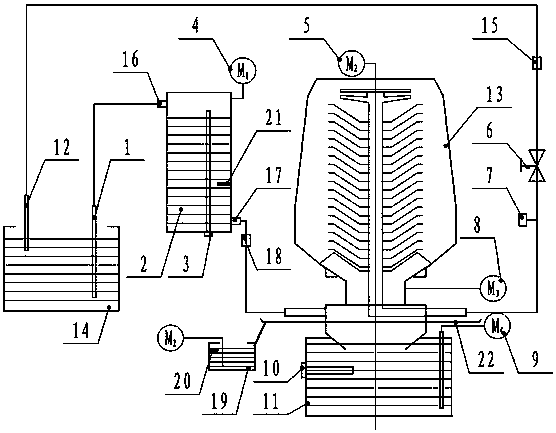

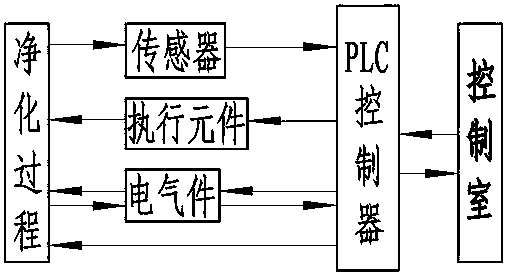

[0019] A fully automatic centrifugal oil purifier, the centrifugal oil purifier is connected with a PLC controller, the PLC controller is provided with a communication port, and the PLC controller is connected with the control room through the communication port to realize remote monitoring and control, which is convenient for users to centralize The body of the PLC controller is equipped with a touch screen and an audible and visual alarm. The touch screen can display the working status, oil outlet pressure and oil temperature in real time. In addition, the centrifugal oil purifier has protection functions such as air suction, high oil temperature, low flow, and leakage. When the above situations occur, the oil purifier will automatically stop, and the sound and light alarm will alarm. The cause of the fault will be displayed on the touch screen in real time, so that users can find out in time Fault, troubleshoot.

[0020] The centrifugal oil purifier includes a fuel tank 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com