Dehydrator for cooling tower

A cooling tower and blade technology, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of increased flow resistance, no reinforcement, large cooling water consumption, etc. Ability to adsorb and divert, avoid material costs, improve water removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

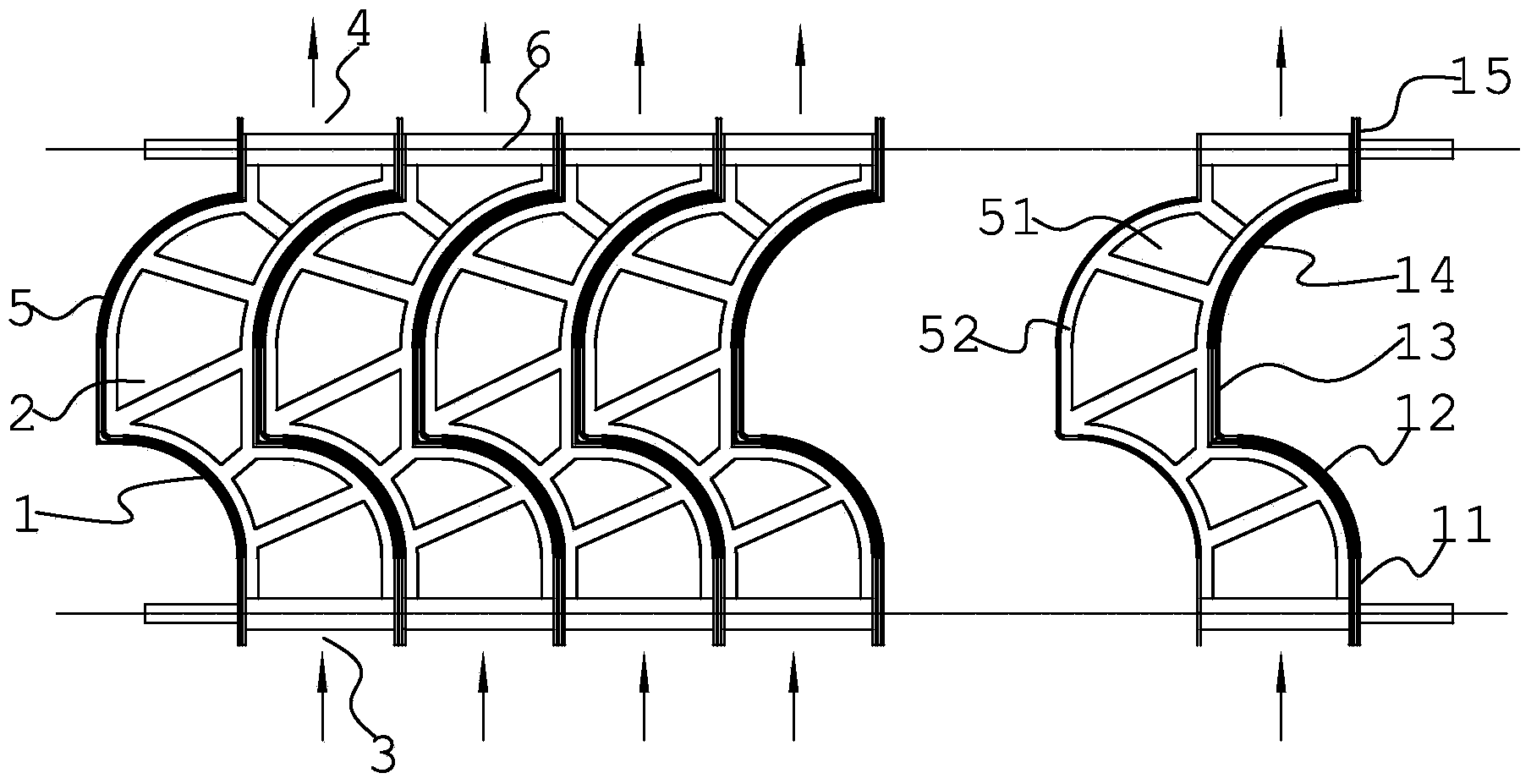

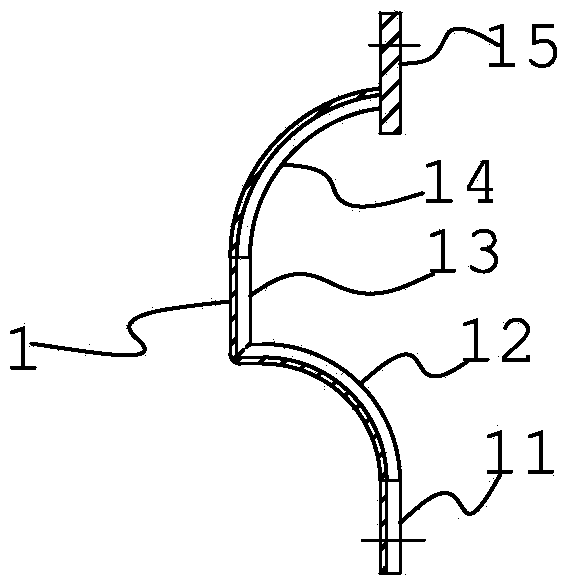

[0022] Such as Figure 1 to Figure 7 A water eliminator for a cooling tower is shown, including a plurality of blades 1; a curved channel 2 for air flow is formed between adjacent blades 1, and the curved channel 2 is a variable cross-sectional structure; the curved channel 2 The cross-sectional area of the middle part is smaller than the cross-sectional area of the upper and lower parts of the curved channel 2; further, the vertical section of the blade 1 includes a first straight line segment 11, a first arc-shaped curve segment 12, a second straight line segment 13 and The second arc curve segment 14; the first straight line segment 11 is located at the air inlet 3; the bending direction of the first arc curve segment 12 is opposite to the bending direction of the second arc curve segment 14; The curvature of an arc curve segment 12 is greater than the curvature of the second arc curve segment 14; the first arc curve segment 12 corresponds to the inner concave surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com