Air discharge monitoring system

A monitoring system, fan technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of air volume and absolute air pressure in abnormal working areas, affecting production, system failures, etc., to avoid unplanned The effect of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

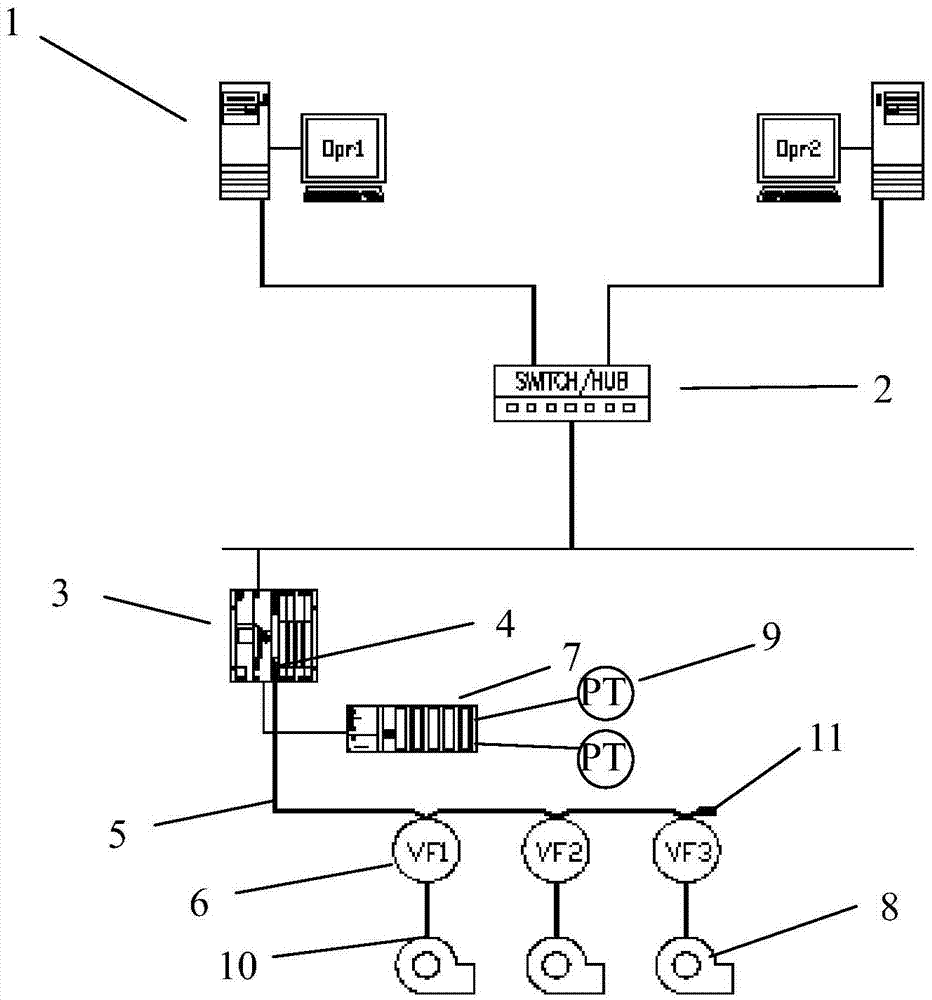

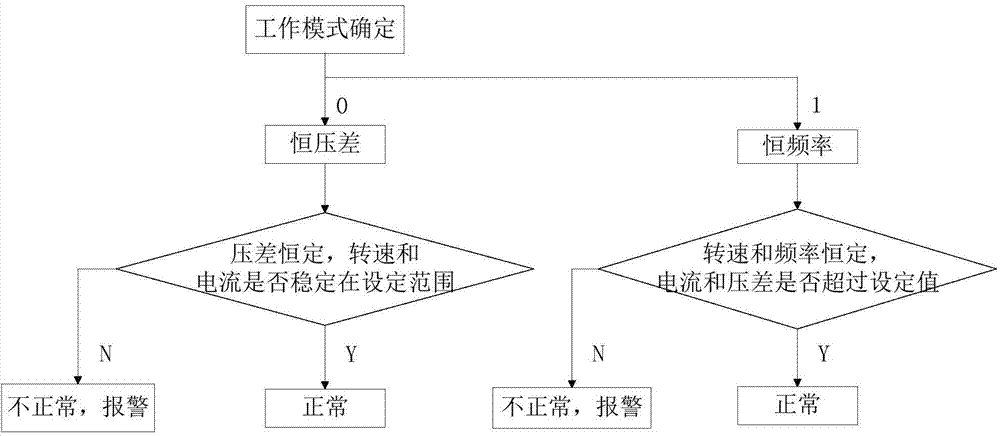

[0032] The present invention aims at the problem that sometimes the air pressure of the existing process equipment exhaust monitoring system is still sufficient to meet the set value requirements due to the blockage of the air pipe, but the air volume and absolute air pressure are both in the abnormal working area, resulting in system failures affecting production. Such as figure 1 As shown, an exhaust air monitoring system is provided, comprising:

[0033] Driver layer equipment for exhaust;

[0034] The processing layer device is used for judging whether the current pipeline is normal according to the relationship between the working parameters of the driving layer equipment and sending an alarm signal when the pipeline is abnormal.

[0035] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com