Waterproof joint of carbon fiber heating cables

A technology of carbon fiber heating and carbon fiber heating wire, which is applied in the direction of cable joints, cable accessories, cable installation, etc., can solve the problems of poor waterproof performance, narrow application range and other problems, achieve good thermal stability, scientific and reasonable design structure, and improve The effect of waterproof performance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

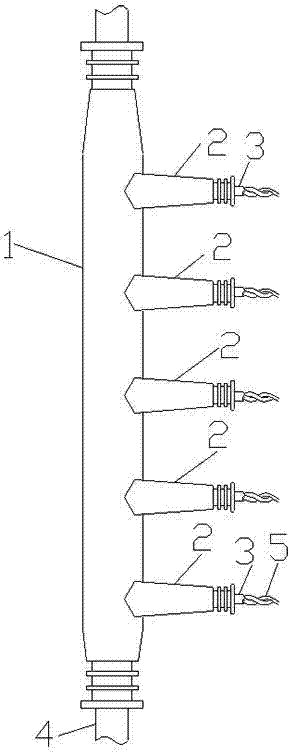

[0017] like figure 1 and Figure 4 As shown, a carbon fiber heating cable waterproof joint is mainly composed of a waterproof joint main body 1, several carbon fiber heating cables 3 and two power supply wires 4, several taps 2 are arranged on one side of the waterproof joint main body 1, power supply wires 4 and carbon fiber heating The cables 3 are respectively fixed inside the main body 1 of the waterproof joint and the tap 2. There are two carbon fiber heating wires 5 inside the carbon fiber heating cable 3. The two carbon fiber heating wires 5 are twisted to each other in a spiral shape inside the carbon fiber heating cable 3. 5. Several carbon fibers 51 are arranged inside.

example 2

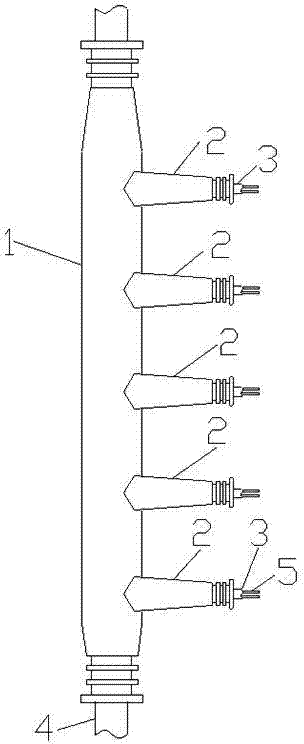

[0019] like figure 2 and Figure 4 As shown, a carbon fiber heating cable waterproof joint is mainly composed of a waterproof joint main body 1, several carbon fiber heating cables 3 and two power supply wires 4, several taps 2 are arranged on one side of the waterproof joint main body 1, power supply wires 4 and carbon fiber heating The cables 3 are respectively fixed inside the main body 1 and the tap 2 of the waterproof joint. Two carbon fiber heating wires 5 are arranged inside the carbon fiber heating cable 3. The two carbon fiber heating wires 5 are arranged parallel to each other inside the double-conducting carbon fiber heating cable 3. Several carbon fibers 51 are arranged inside.

example 3

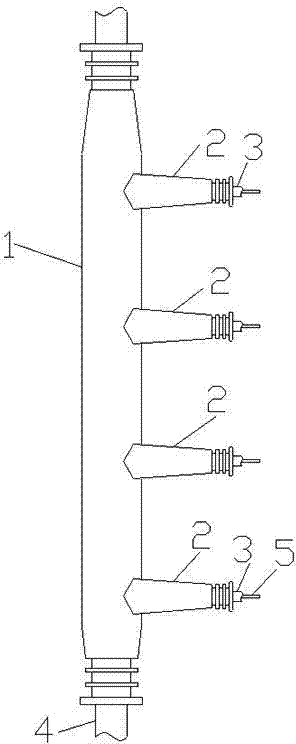

[0021] like image 3 and Figure 4 As shown, a carbon fiber heating cable waterproof joint is mainly composed of a waterproof joint main body 1, a carbon fiber heating cable 3 and two power supply wires 4, and an even number of taps 2, power supply wires 4 and carbon fiber heating cables are arranged on one side of the waterproof joint main body 1 3 are respectively fixed inside the main body 1 of the waterproof joint and the tap 2, a carbon fiber heating wire 5 inside the carbon fiber heating cable 3, and several carbon fibers 51 are arranged inside the carbon fiber heating wire 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com