Loudspeaker magnetic circuit structure

A loudspeaker and magnetic circuit technology, which is applied in the field of loudspeakers, can solve the problems of increasing the thickness of the loudspeaker, difficulty in increasing the magnetic flux, and difficulty in obtaining the shape, etc., to achieve the effect of increasing the B value of the magnetic flux, increasing the B value of the magnetic flux, and solving the effect of large magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

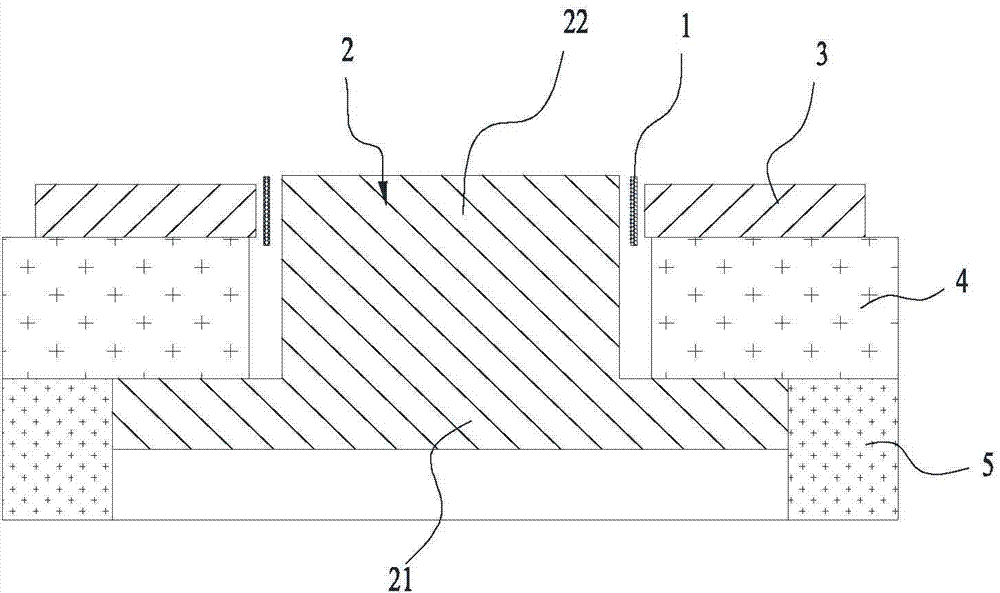

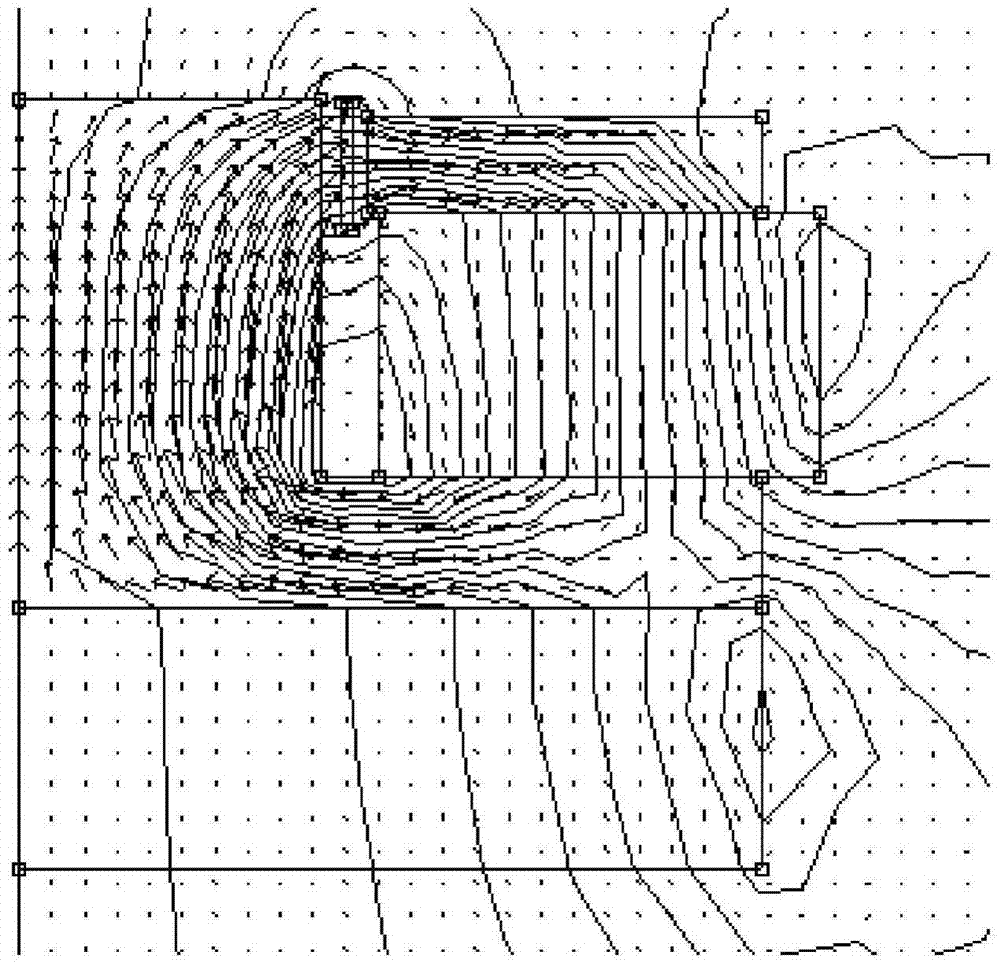

[0033] Such as figure 2 A loudspeaker magnetic circuit structure shown includes a voice coil 1, a T iron 2, a front splint 3, a main magnetic steel 4 and a first side magnetic steel 5, and the T iron 2 has a bottom plate 21 and a vertically protruding from the bottom plate 21. The cylinder 22, the main magnet 4, the front splint 3 and the voice coil 1 are all looped around the periphery of the cylinder 22, the main magnet 4 is stacked on the top surface of the bottom plate 21, the front splint 3 is stacked on the top surface of the main magnet 4; the voice coil 1 It is located between the socket of the front splint 3 and the outer wall of the cylinder 22, and a magnetic gap is formed between the voice coil 1 and the front splint 3 and the outer wall of the cylinder 22 respectively; The first side magnetic steel 5 is in close fit or clearance fit with the lower surface of the main magnetic steel 4 .

[0034] The main magnetic steel 4 is the main magnetic energy provider in th...

Embodiment 2

[0039] Such as Figure 4 Shown is Embodiment 2 of a loudspeaker magnetic circuit structure of the present invention. The differences between Embodiment 2 and Embodiment 1 are:

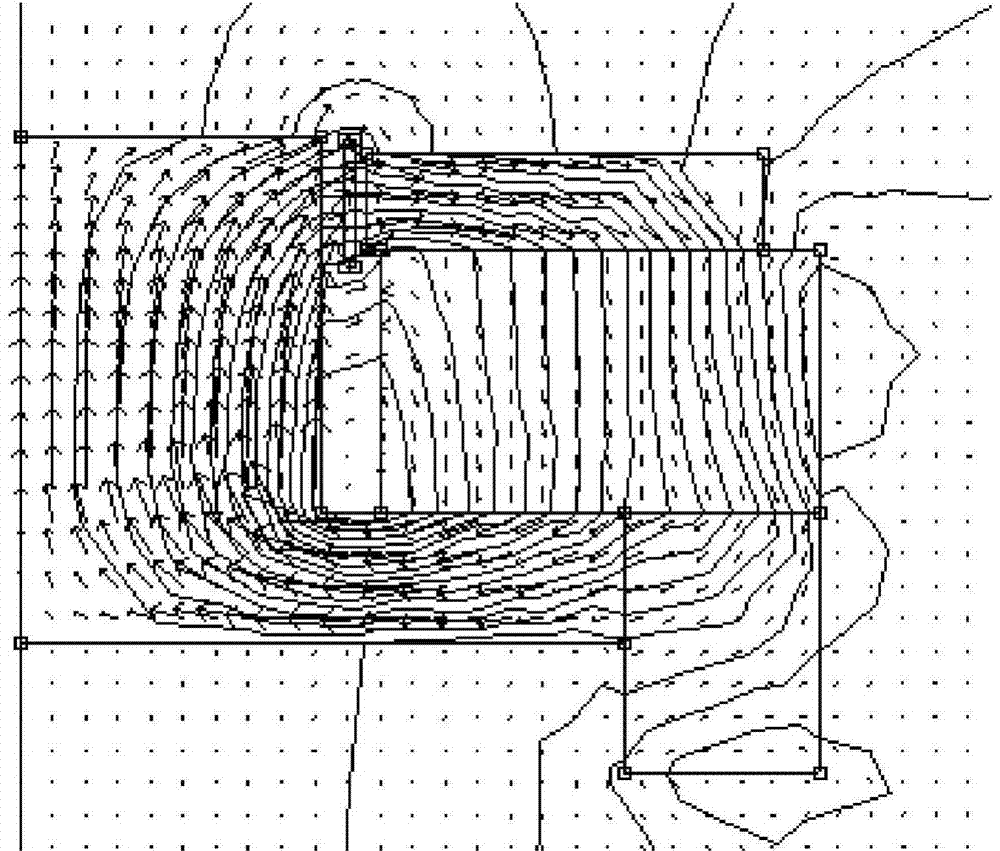

[0040] A first auxiliary magnet 6 is provided on the lower surface of the bottom plate 21 , and the first auxiliary magnet 6 closely fits or has a clearance fit with the inner wall of the pocket of the first side magnet 5 . The function of the first secondary magnet 6 is to increase the magnetic flux of the magnetic circuit, and at the same time, the first side magnet 5 can also reduce the magnetic flux leakage of the first secondary magnet 6 . The magnetic direction of each component after adding the first auxiliary magnetic steel 6 is as follows: Figure 8 As shown, the magnetic orientation of each component can also be as Figure 8 Contrary to what is shown in .

[0041] If the first secondary magnetic steel 6 is lower than the first side magnetic steel 5, the speaker can be made thinner as a who...

Embodiment 3

[0044] Such as Figure 9 Shown is Embodiment 3 of a loudspeaker magnetic circuit structure of the present invention. The difference between Embodiment 3 and Embodiment 2 is:

[0045] The top surface of the cylinder 22 is provided with a second secondary magnetic steel 7, which is located in the top surface of the cylinder 22, to avoid affecting the magnetic gap formed between the T iron 2 and the main magnetic steel 4, the second The auxiliary magnetic steel 7 can increase the magnetic flux, and can further reduce the flux leakage between the T iron 2 and the main magnetic steel 4 . The second secondary magnetic steel 7 is all round or rectangular, or other arbitrary polygonal shapes, and the circular or rectangular shape is better for increasing the magnetic flux B, and its magnetic field line circuit diagram is as follows Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com