A high-strength aluminum alloy high-thickness ratio net-shape isothermal forging die

An isothermal forging, aluminum alloy technology, applied in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of small high-to-thickness ratio, difficult to form high-to-thickness ratio forgings, poor high temperature fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 17075

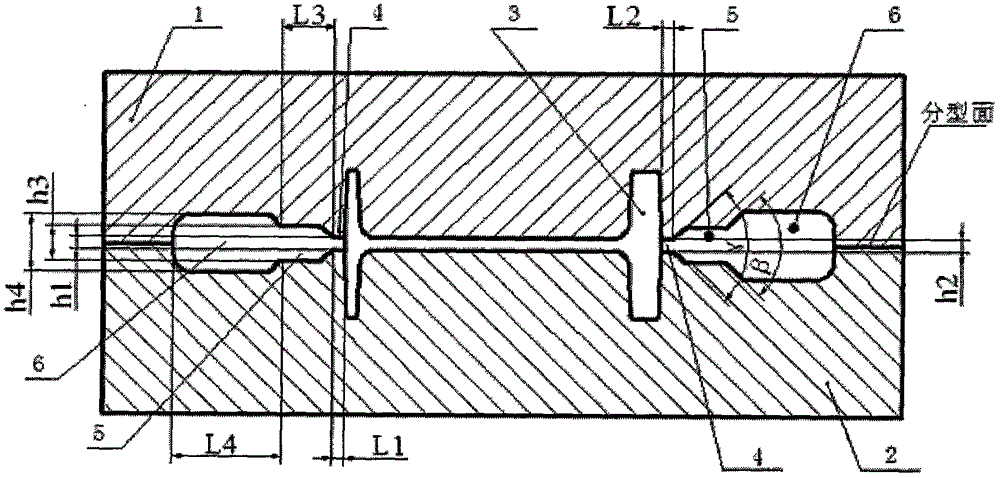

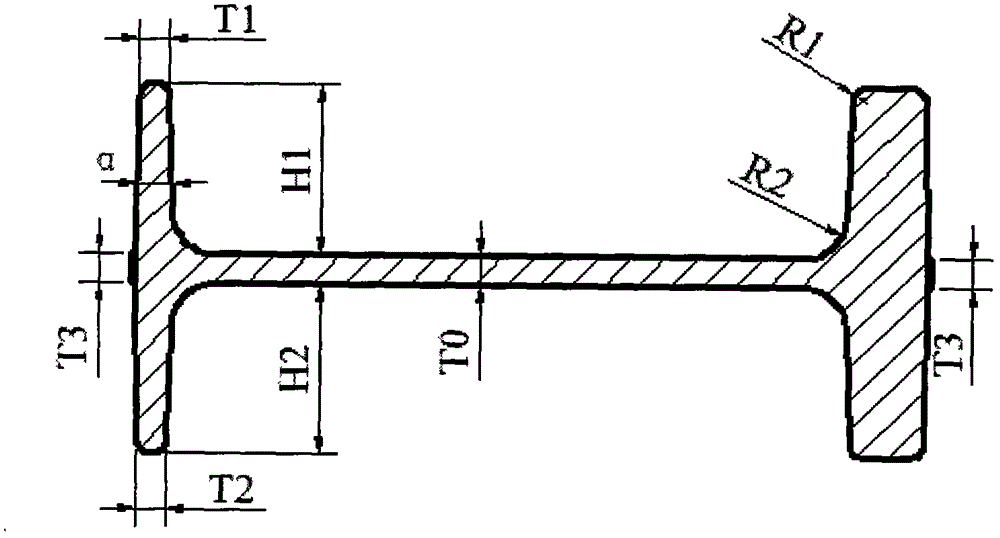

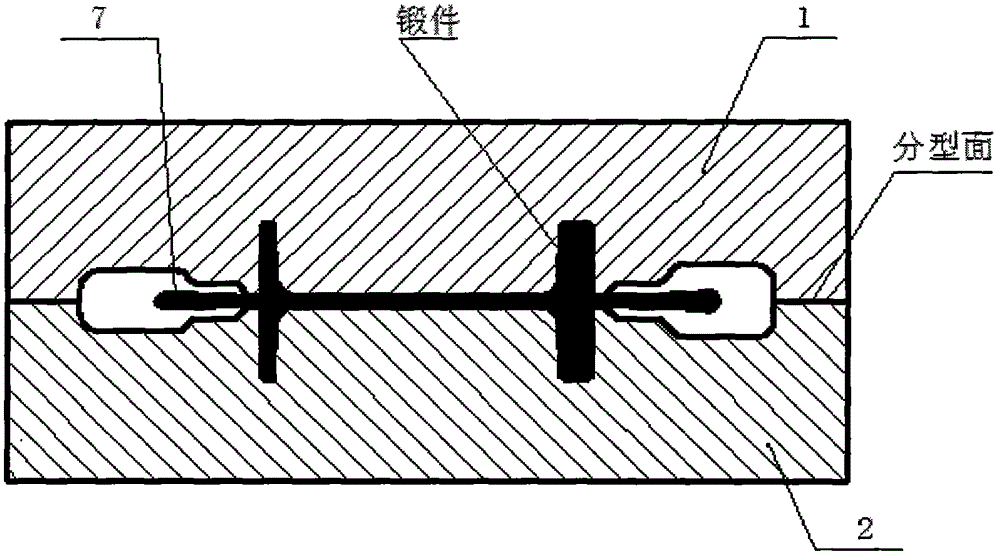

[0022] Example 1 7075 aluminum alloy forging die

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the 7075 aluminum alloy forging die includes an upper die 1, a lower die 2, and a forging cavity 3 located between the upper die 1 and the lower die 2, and an overflow cavity is arranged between the upper die 1 and the lower die 2, and the overflow The material chamber is composed of three areas, namely the damping control zone 4, the damping release area 5 and the overflow storage chamber 6. The heights of the three partitions of the overflow cavity are respectively: h1=h2=1.2mm, h3=6mm, h4=10mm. The width of each area of the overflow chamber meets the following requirements: L1=L2=1.5mm, L3=9mm, L4=19mm. The overflow chamber has two height transition steps with included angles β and γ, γ=60°, β=90°. The h1 and h2 are the heights of the left and right damping control bands 4 respectively, h3 is the height of the damping release zone 5, h4 is the he...

Embodiment 22024

[0025] Example 2 2024 aluminum alloy forging die

[0026] Such as Figure 5 As shown, a 2024 aluminum alloy forging die includes an upper die 1, a lower die 2, and a forging cavity 3 between the upper die 1 and the lower die 2, and an overflow cavity is arranged between the upper die 1 and the lower die 2, and the overflow The material chamber is composed of three areas, namely the damping control zone 4, the damping release area 5 and the overflow storage chamber 6. The heights of the three partitions of the overflow cavity are respectively: h1=h2=1.5mm, h3=6mm, h4=10. The width of each area of the overflow cavity is: L1=L2=1.8mm, L3=14mm, L4=27mm. The overflow chamber has two height transition step angles β and γ, the values of which are respectively: γ=60°, β=90°. The h1 and h2 are the heights of the left and right damping control bands 4 respectively, h3 is the height of the damping release zone 5, h4 is the height of the overflow storage chamber 6, and L1 and L2 ar...

Embodiment 36061

[0028] Example 3 6061 aluminum alloy forging die

[0029] Such as Figure 6 As shown, the 6061 aluminum alloy forging die includes an upper die 1, a lower die 2, and a forging cavity 3 between the upper die 1 and the lower die 2, and an overflow cavity is arranged between the upper die 1 and the lower die 2, and the overflow The material chamber is composed of three areas, namely the damping control zone 4, the damping release area 5 and the overflow storage chamber 6. The heights of the three partitions of the overflow cavity are respectively: h1--h2=1.5mm, h3=4mm, h4=10. The width of each area of the overflow cavity is: L1=L2=1.5mm, L3=13mm, L4=28mm. The overflow chamber has two height transition step angles β and γ, the values of which are respectively: γ=60°, β=90°. The h1 and h2 are the heights of the left and right damping control bands 4 respectively, h3 is the height of the damping release zone 5, h4 is the height of the overflow storage chamber 6, and L1 and L2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com