Leakage-proof bottle cap

A technology for leaking bottle caps and bottle caps, which is applied in the field of bottle caps, can solve problems such as long convex 3 deviation, hidden dangers of beverage safety, air leakage, etc., and achieve the effect of preventing deviation and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

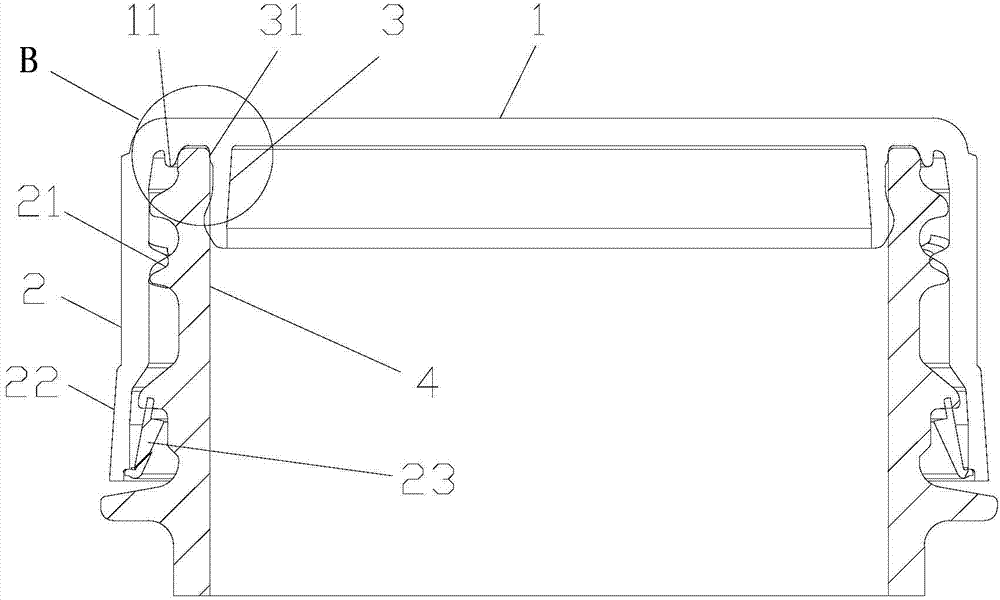

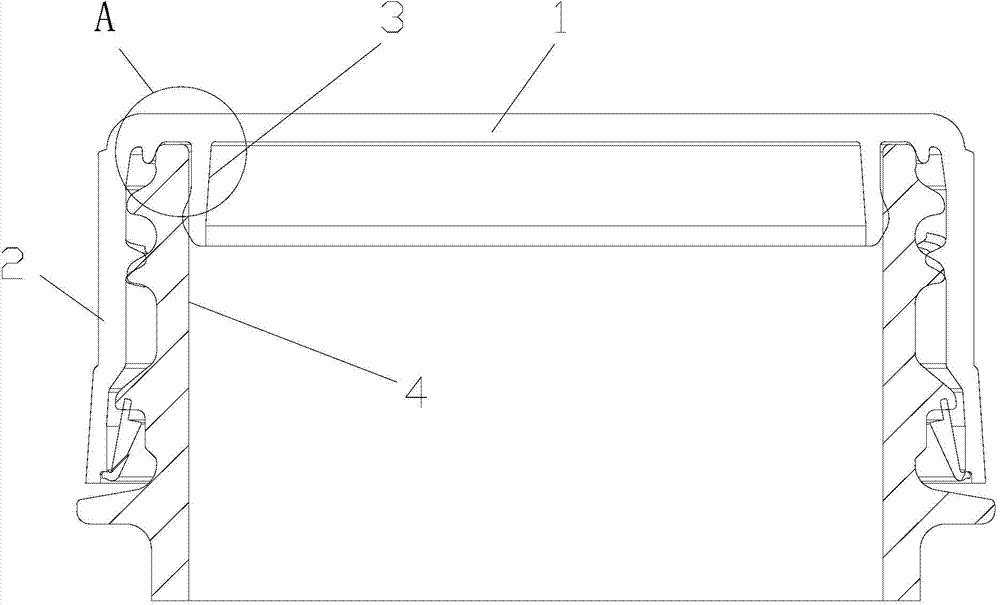

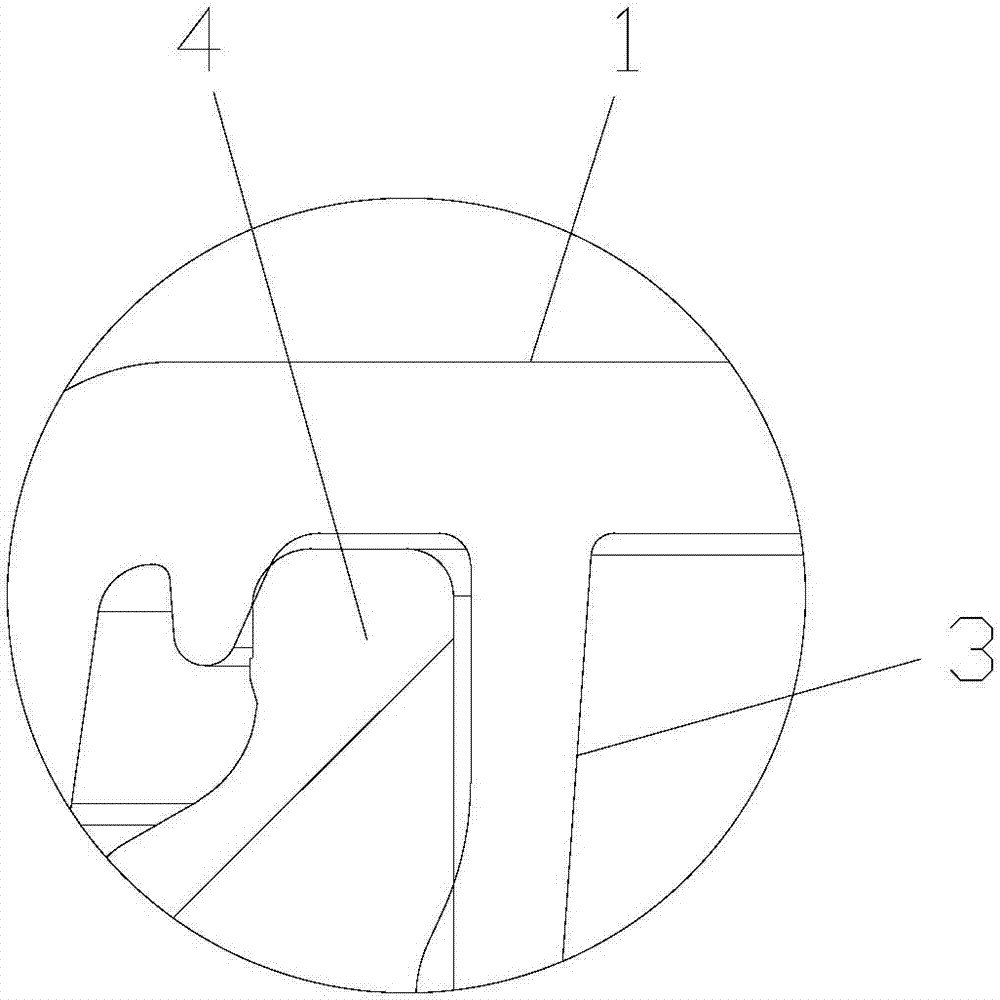

[0016] see image 3 and Figure 4 , which depicts the leak-proof bottle cap of the present invention, which includes a cover surface 1 and a peripheral wall 2 extending downward along the edge of the cover surface 1. On the inner top surface of the cover surface 1, there is concentrically arranged a downward extending and circumferentially closed The long protrusion 3 has a sealing part 31 on the outer periphery of the upper end of the long protrusion 3 that is tightly fitted with the inner edge of the upper end of the bottle mouth 4 . The leak-proof bottle cap of this embodiment also includes a leak-proof ring 11 arranged on the inner top surface of the cover surface 1 and between the peripheral wall 2 and the elongated protrusion 3, and the upper end of the bottle mouth 4 is pressed against the leak-proof ring 11 and the Between the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com