Breathable shoe sole with slip-resistant device

A technology of anti-skid device and anti-skid block, which is applied in the direction of sole, footwear, application, etc., can solve the problem of anti-skid of shoes, and achieve the effect of good anti-skid, large friction and avoiding heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

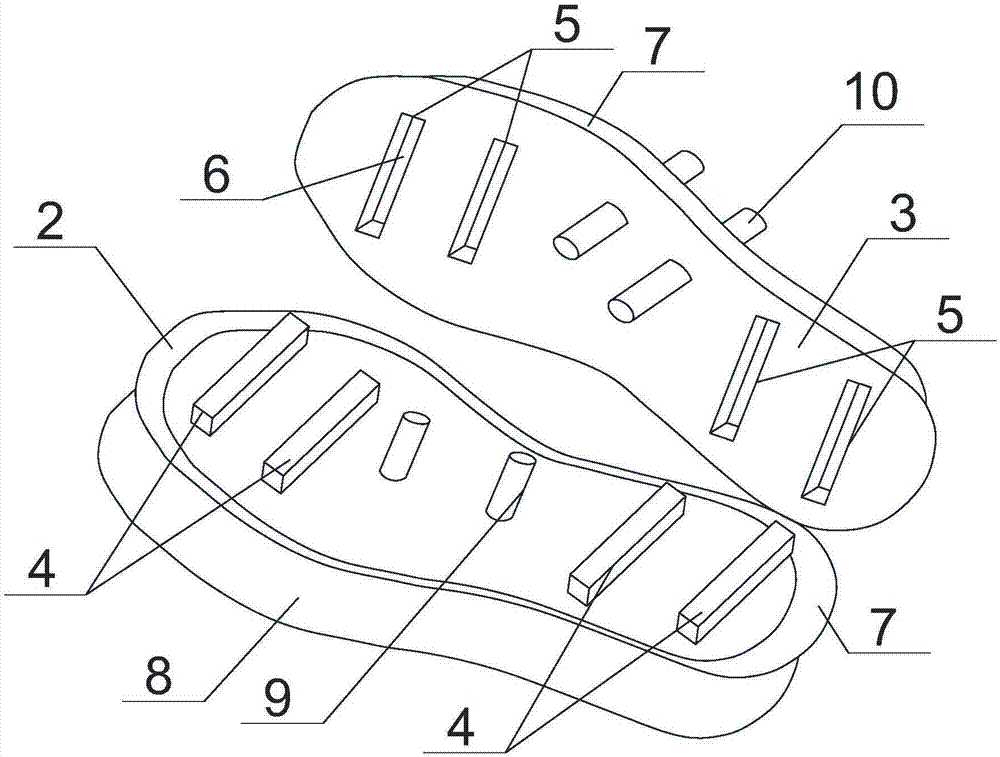

[0021] Such as figure 1 , figure 2 As shown, the present invention is provided with the breathing sole of anti-skid device, comprises the sole body 1 that ventilation device is installed, and described sole body 1 comprises the bottom layer that contacts with ground, and described bottom layer comprises upper bottom layer 2, upper bottom layer 2 below connection. The lower bottom layer 3, the lower surface of the upper bottom layer 2 is provided with a downwardly protruding first anti-slip block 4, the lower surface of the lower bottom layer 3 is provided with a downwardly protruding second anti-slip block 5, and the second anti-slip block 5 is internally provided with The groove 6 for the first anti-skid block 4 to be fully inserted into the second anti-skid block 5 , the inner wall of the groove 6 is covered with an adhesive layer bonding the first anti-skid block 4 .

[0022] The implementation of the present invention is as follows: in the initial state, the lower bottom...

Embodiment 2

[0024] Based on embodiment 1, rubber rings 7 are arranged on the lower surfaces of the upper bottom layer 2 and the lower bottom layer 3 , and the rubber rings 7 are evenly arranged around the edges of the lower surfaces of the upper bottom layer 2 and the lower bottom layer 3 . The rubber ring is to slow down the wear speed of the upper bottom layer and the lower bottom layer except the anti-skid block. The rubber ring also has a certain anti-skid effect.

Embodiment 3

[0026] Based on the above-mentioned embodiment, the ventilation device includes an air cushion layer 8 positioned above the upper bottom layer 2, the upper bottom layer 2 is provided with a first air duct 9 communicating with the air cushion layer 8, and the lower bottom layer 3 is provided with a first air duct 9 connected to the first air duct layer. 9 communicates with the second air duct 10, the first air duct 9 and the second air duct 10 are all in communication with the outside world. The diameter of the second air-guiding tube 10 is greater than that of the first air-guiding tube 9 , and when the upper bottom layer 2 and the lower bottom layer 3 are connected, the first air-guiding tube 9 is inserted into the second air-guiding tube 10 . The tube lengths of the first air guide tube 9 and the second air guide tube 10 are less than the heights of the first anti-slip block 4 and the second anti-slip block 5 respectively. The first air guide tube and the second air guide tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com