Method of preparing basic chromium sulfate tanning agent from chromite sulfuric acid leachate

A technology of chromium sulfate tanning agent and leachate, which can be used in small hide/big hide/leather/fur treatment, small hide/big hide/leather/fur chemical treatment, tanning treatment, etc. It can solve iron removal difficulties, etc. problem, to achieve the effect of complete iron removal, good use effect and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The following preparation method of sulfuric acid leaching solution of chromite ore is as follows: grind chromite ore into particles, add sulfuric acid into the reactor, and then add sulfuric acid. The liquid-solid ratio of sulfuric acid and mineral powder is (1-4): 1mL / g, 60-160 rev / min, heat up, at a temperature of 90-160°C, add a catalyst for acidolysis reaction, the reaction temperature is 110-170°C, the reaction time is 1-8h, filter the reaction solution, remove the filter residue, and obtain chromium iron ore sulfuric acid leaching solution.

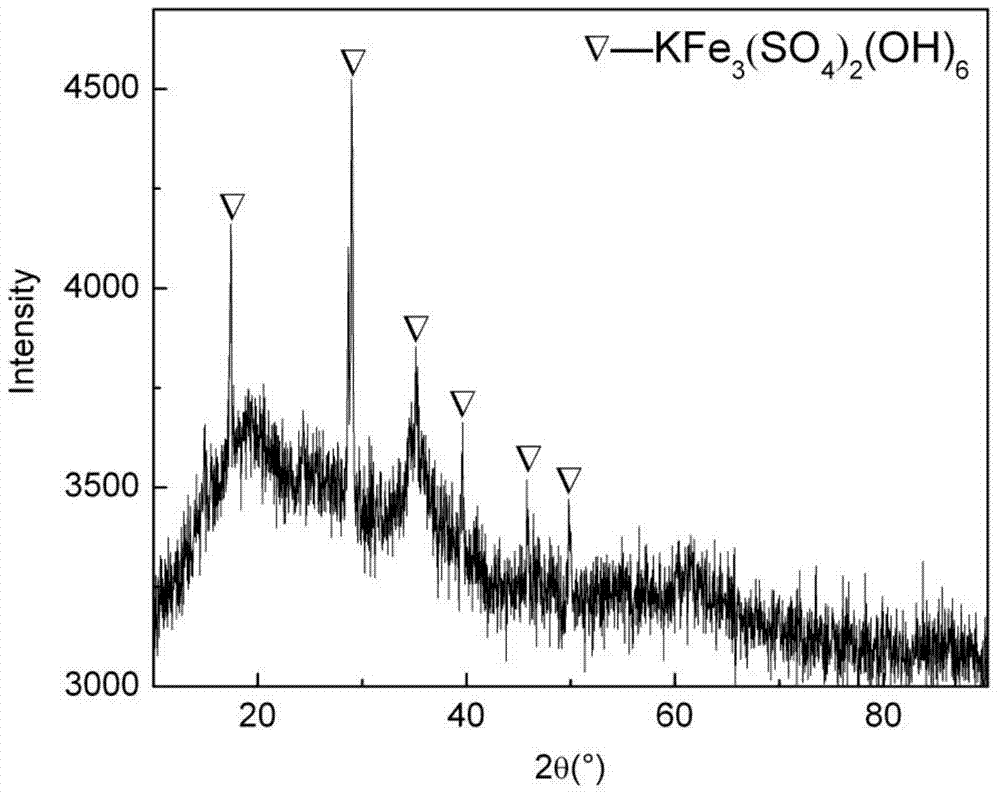

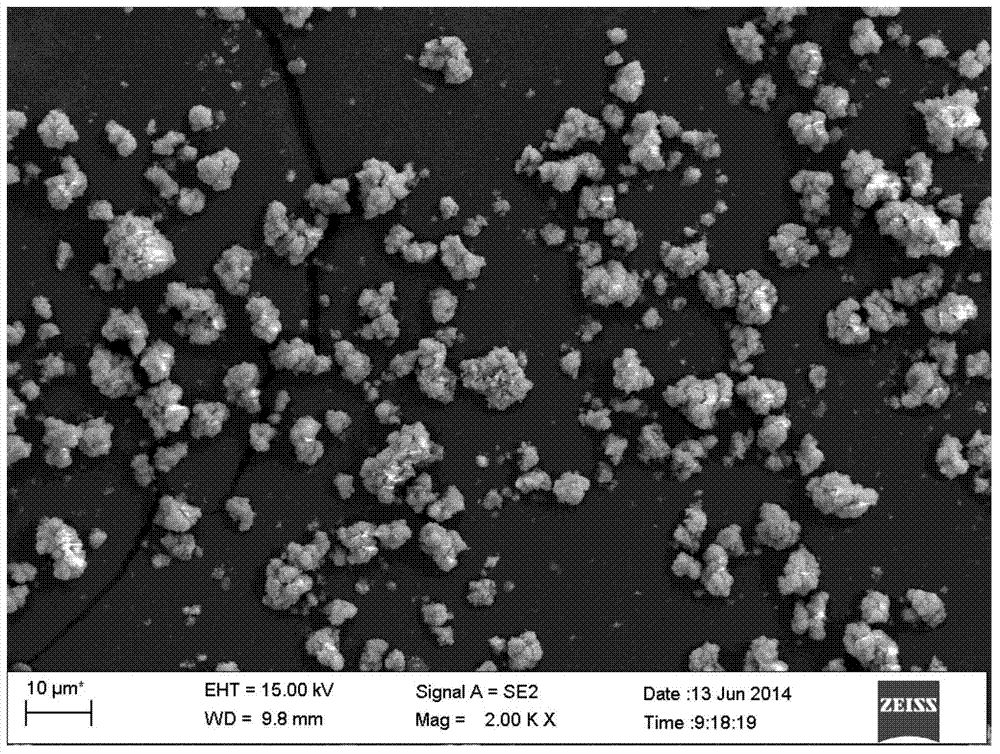

[0051] The used chaosite seed crystals and goethite seed crystals have a mass purity of >97% and a powder particle size of <74 μm.

Embodiment 1

[0053] Using 500mL chromite sulfuric acid leaching solution as raw material, the concentration of metal ions in the leaching solution is [Cr 3+ ]=26.4g / L, [Fe 3+ ]=13.2g / L, [Mg 2+ ]=3.7g / L, [Al 3+ ]=4.5g / L.

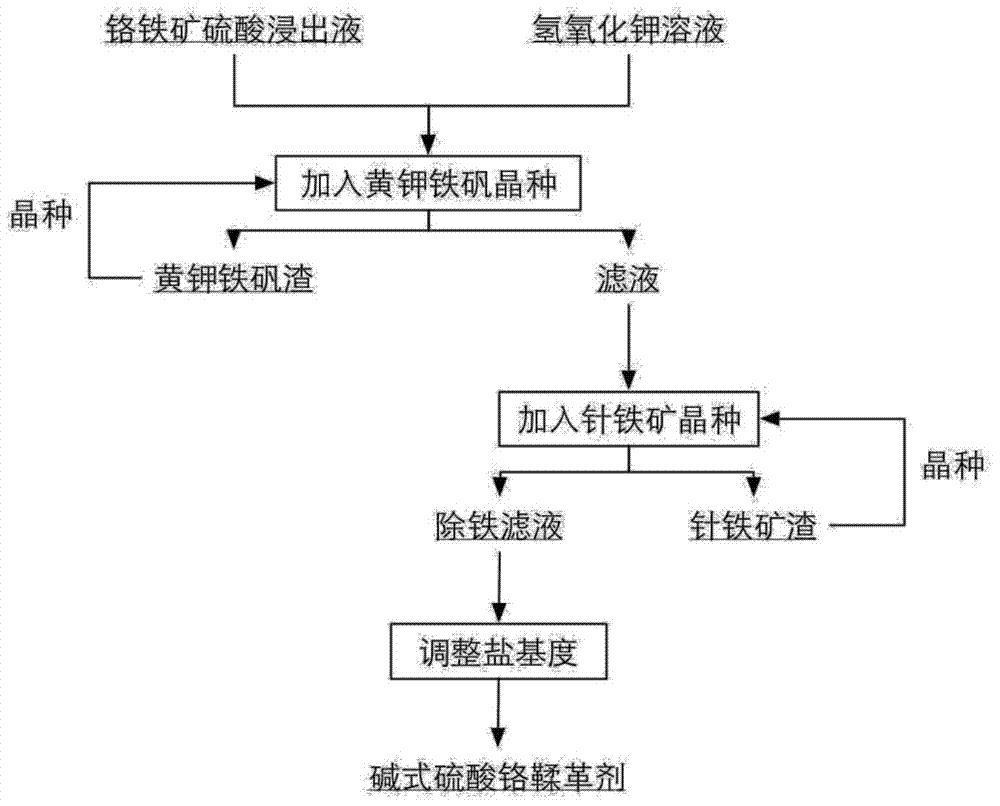

[0054] use as figure 1 The schematic diagram of the process of preparing basic chromium sulfate tanning agent by chromite sulfuric acid leaching solution shown, the present embodiment prepares the method for basic chromium sulfate tanning agent by chromite sulfuric acid leaching solution, and concrete steps are as follows:

[0055] Step 1: Inject the chromite sulfuric acid leaching solution into the reactor, turn on heating and stirring, the stirring speed is 2400rad / s (arc per second), raise the temperature of the leaching solution to 90°C, and slowly drop 2.5mol / L into the reactor Potassium hydroxide solution until the pH value of the solution reaches 2.3 and remains unchanged for at least 1 min;

[0056] Then pour 2.5g of jarosite seed crystal powder into the reac...

Embodiment 2

[0066] Using 500mL chromite sulfuric acid leaching solution as raw material, the concentration of metal ions in the leaching solution is [Cr 3+ ]=30.7g / L, [Fe 3+ ]=19.8g / L, [Mg 2+ ]=5.2g / L, [Al 3+ ]=6.6g / L.

[0067] The present embodiment prepares the method for basic chromium sulfate tanning agent by chromite ore sulfuric acid leaching liquor, concrete steps are as follows:

[0068] Step 1: Inject the chromite sulfuric acid leaching solution into the reactor, turn on heating and stirring at a stirring speed of 1800rad / s, raise the temperature of the leaching solution to 85°C, and slowly add 3mol / L sodium hydroxide solution dropwise into the reactor to the solution The pH value reaches 1.7 and remains unchanged for at least 1 minute;

[0069] Pour 1g of jarosite seed crystal powder into the reactor, keep the stirring speed at 1800rad / s for aging reaction for 150min, and monitor the pH value of the solution by dropping the above-mentioned sodium hydroxide solution in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com