Circulating type automatic iron removing machine

A circulating type iron remover technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of magnetic medium adsorption accumulation, inability to clean in time, unfavorable adsorption of iron impurities, etc., to improve adsorption capacity , Simple structure, complete effect of iron removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the invention will be further described below in conjunction with the accompanying drawings and embodiments.

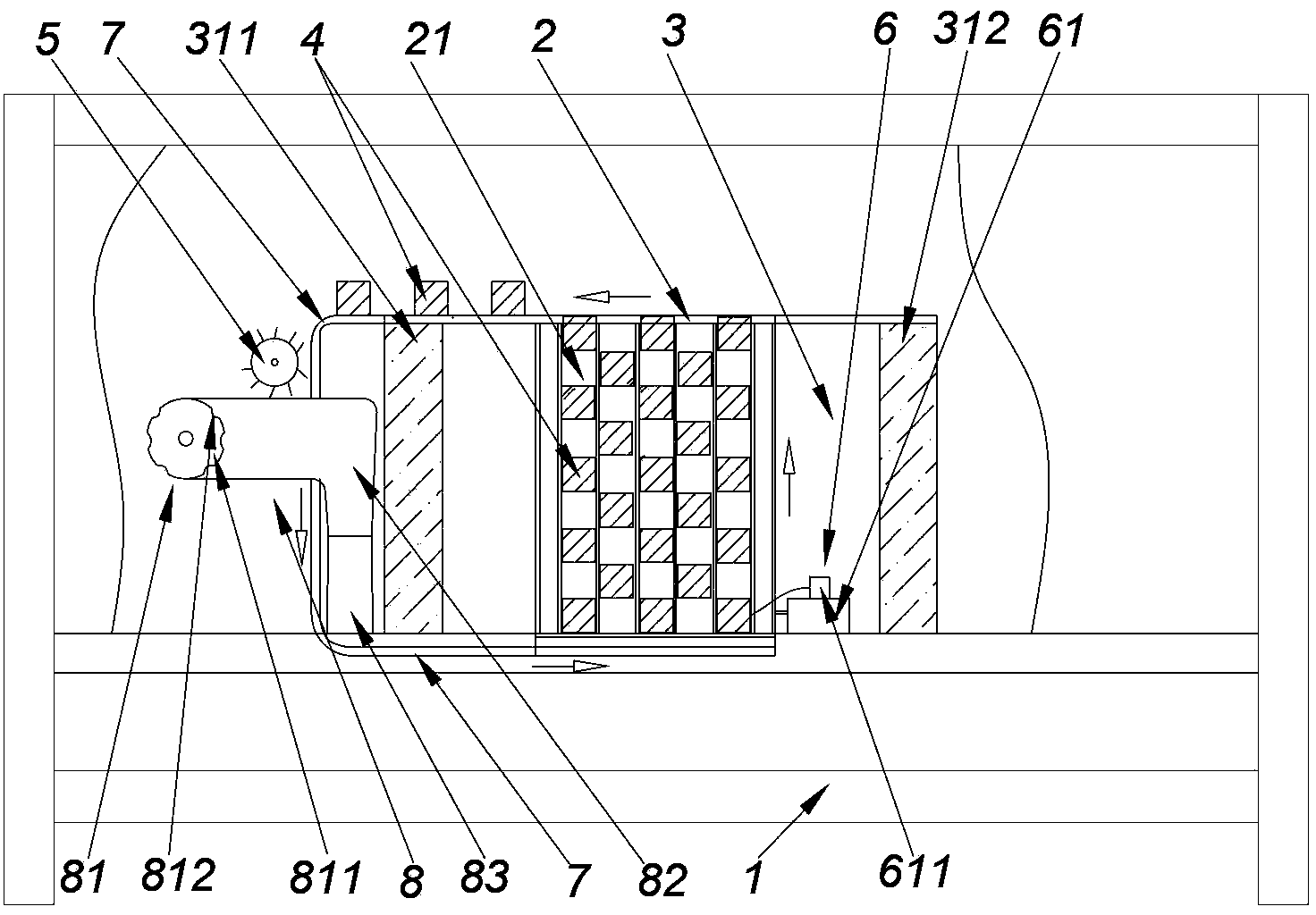

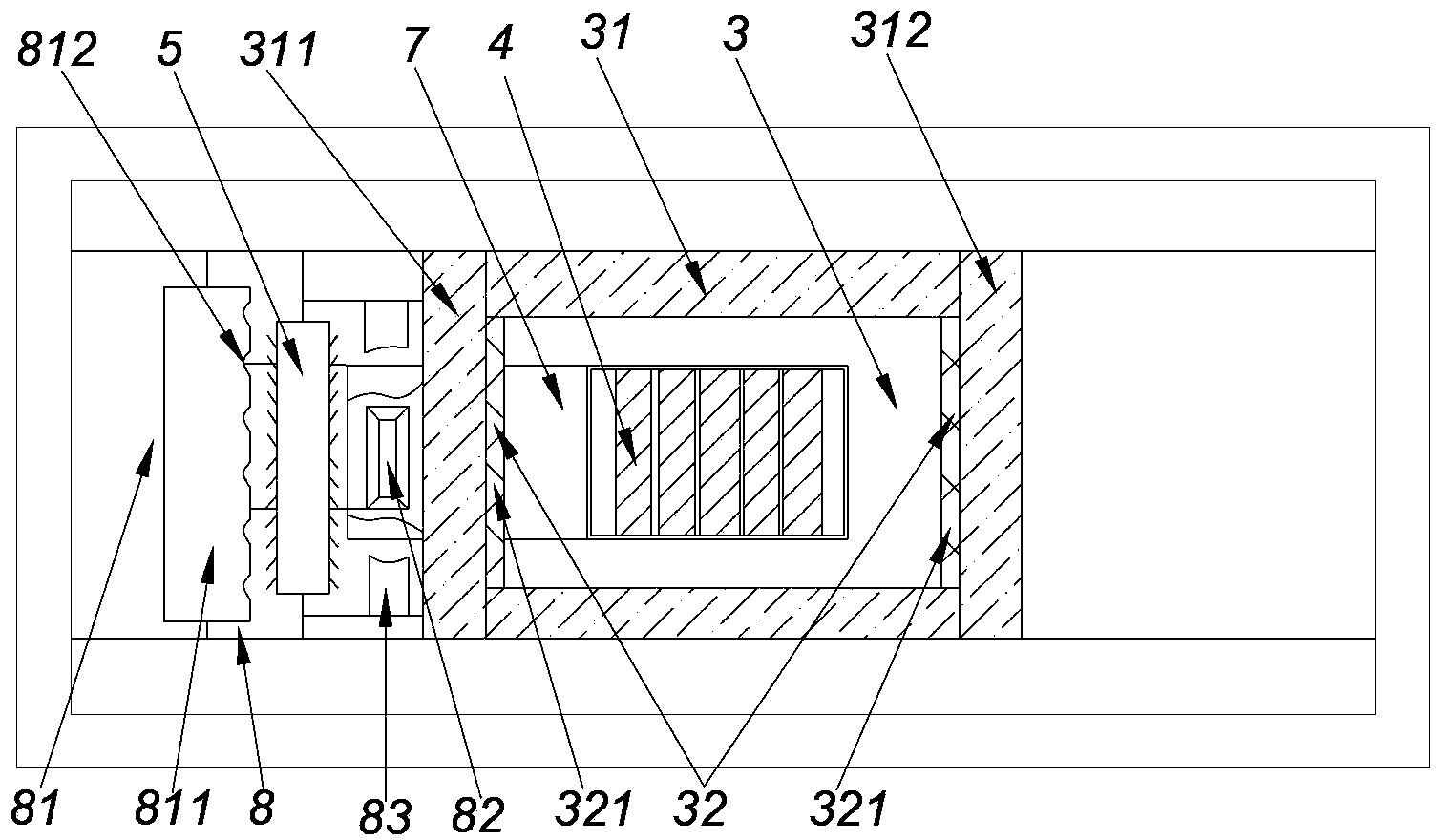

[0019] Such as figure 1 , 2 As shown, the iron remover of this embodiment includes a frame 1, on which a working chamber 2 and a magnetic region 3 are installed, the working chamber 2 is surrounded by the magnetic region 3, and the surroundings of the magnetic region 3 are closed by four soft magnetic bodies 31. Up and down openings, a set of permanent magnet groups 32 are arranged on the soft magnet 31, and the permanent magnet group 32 includes a pair of permanent magnets 321 with different poles facing each other. The permanent magnets 321 are respectively arranged on the left soft magnet 311 and the right soft magnet 312. Above, the permanent magnet 321 will generate a magnetic field in the magnetic zone 3, and the non-named magnetic poles between the permanent magnets 321 form a closed magnetic circuit with continuous magnetic flux circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com