Pile extracting construction method

A technology of pile position and pile alignment, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problem of incomplete removal of waste piles, and achieve the effect of easy pile lifting and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

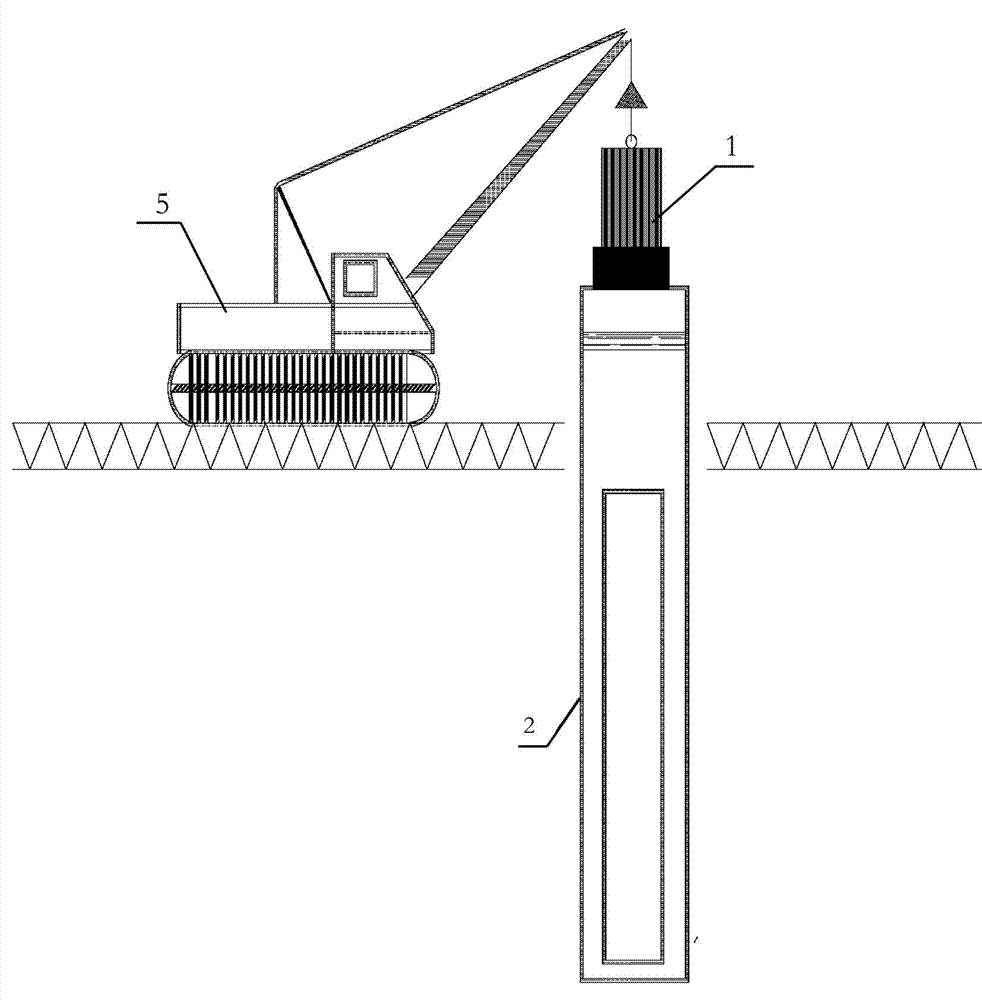

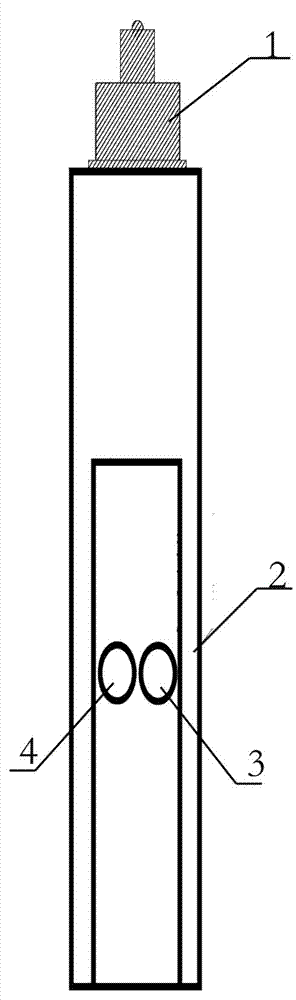

[0018] Example: see figure 1 A kind of construction method of extracting piles, it comprises the following steps:

[0019] 1) First use the seismic geophysical method to preliminarily determine the general position of the waste pile, then use a small auger to detect and determine the specific pile position, and then use an excavator to excavate a 1-meter-deep trench, and adopt conventional manual digging in the trench Pile construction technology Manual excavation with a diameter of 1000mm and a depth of 2 meters, while digging and supporting, digging to 2 meters below the surface and using steel brazing to find out the exact position of the square pile, and determine the pile position that needs to be pulled out.

[0020] 2) Considering the deep burial depth of the pile top, it is necessary to adopt moso bamboo tube support measures, and additionally equip water pumps for precipitation treatment. Considering that the distance between the piles is small, the jump-pull met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com