Multi-hydraulic-cylinder driving type top-drive casing pipe feeding tool

A tool-feeding and driving technology, which is applied to drilling equipment, drilling equipment and methods, earthwork drilling and production, etc., can solve the problems of low operation efficiency, complicated operation, and high manufacturing costs, so as to improve the degree of automation and reduce manufacturing costs. Cost, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

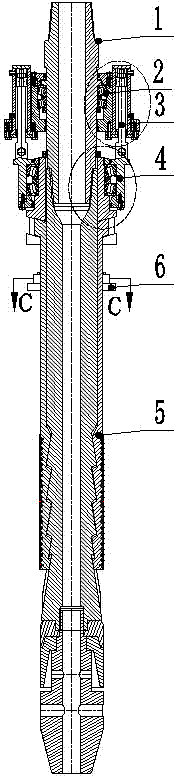

[0029] refer to figure 1 , a multi-hydraulic cylinder-driven top drive casing feeding tool, including a suspension mandrel 1, the suspension mandrel 1 is covered with a connection assembly 2, the lower end of the connection assembly 2 is fixedly connected with the hydraulic cylinder assembly 3 through bolts, and the hydraulic pressure The lower end of the cylinder assembly 3 is connected with the pin shaft of the transmission assembly 4, the lower end of the transmission assembly 4 is connected with the clamping assembly 5, and the clamping assembly 5 is fixed with an anti-collision ring 6 by external bolts;

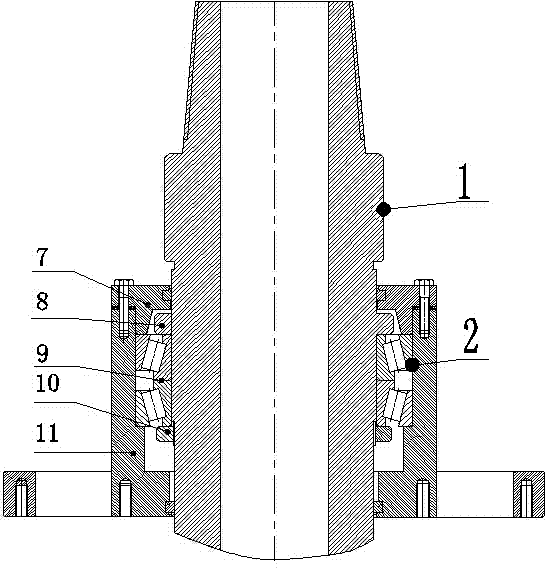

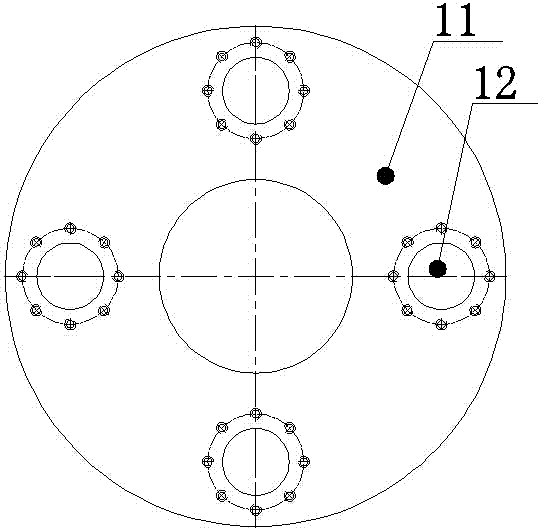

[0030] refer to figure 1 , 2 , The connection assembly 2 includes a small bearing end cover 7, a small tapered roller bearing 9, a small round nut 10, and a suspension tube 11. The diameter of the inner circular through hole of the suspension mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com