Control ring for a hydrostatical device

A control ring and control piston technology, which is applied to the components of the pumping device for elastic fluids, pump control, liquid fuel engines, etc., can solve problems such as leakage, and achieve the effect of simple connection and prevention of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Only two embodiments of the invention are shown and described below, simply by way of illustration of one mode of carrying out the invention. All illustrations are schematic.

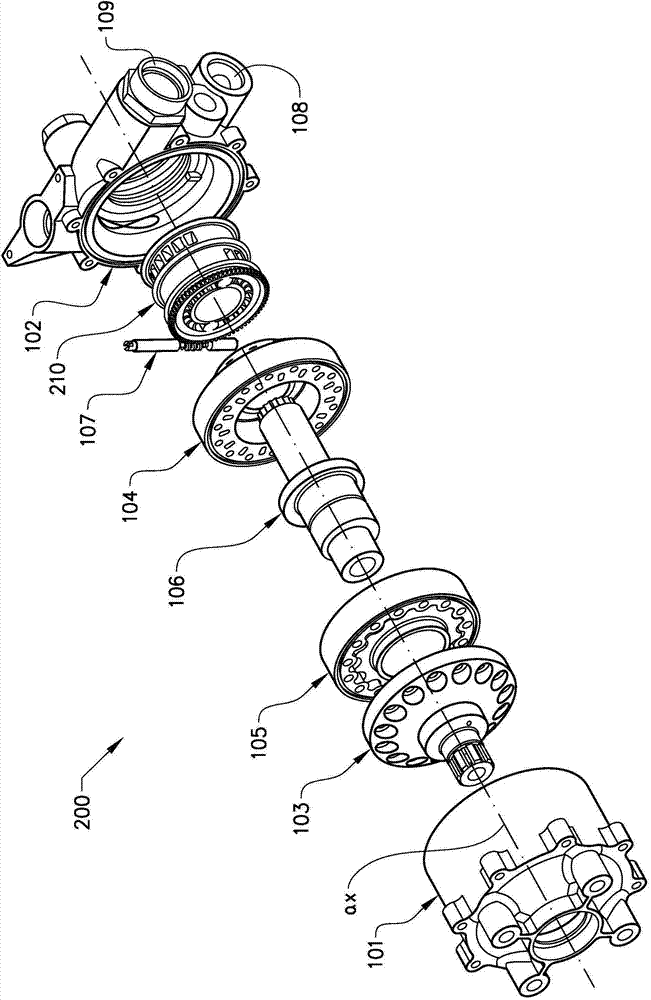

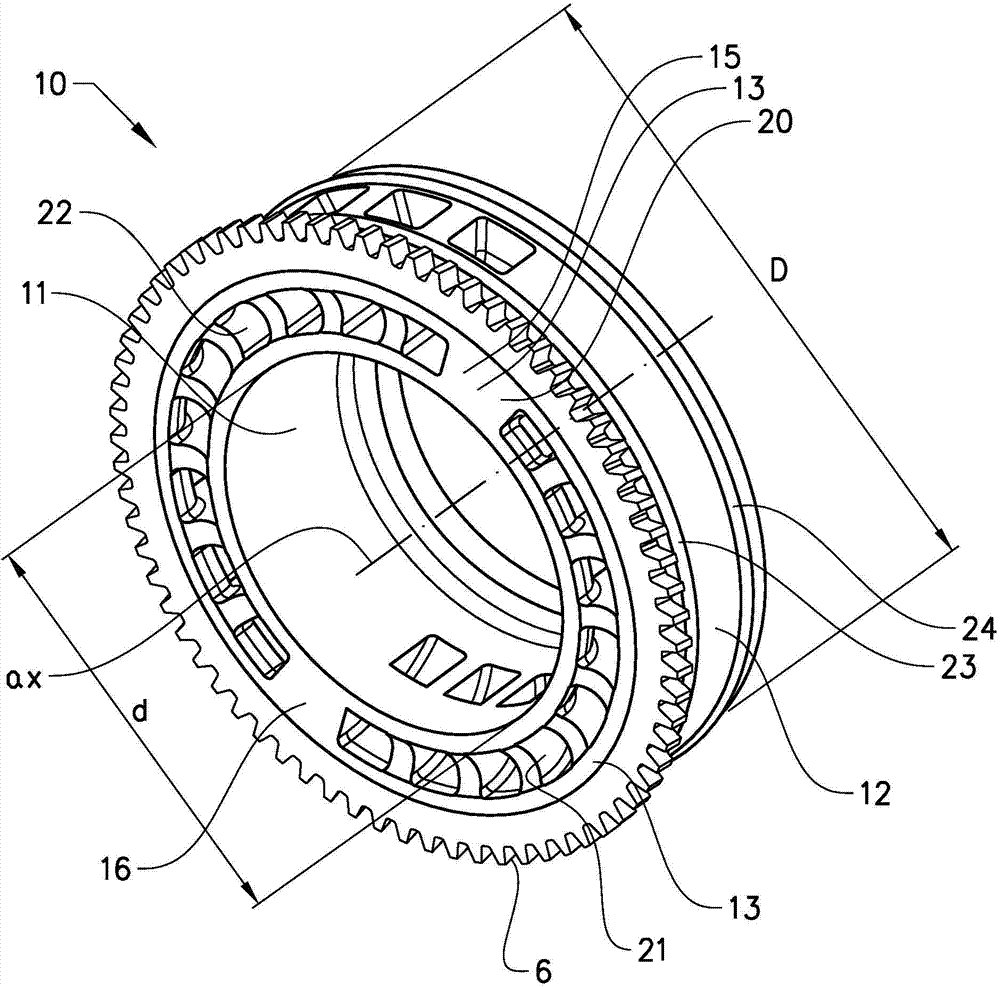

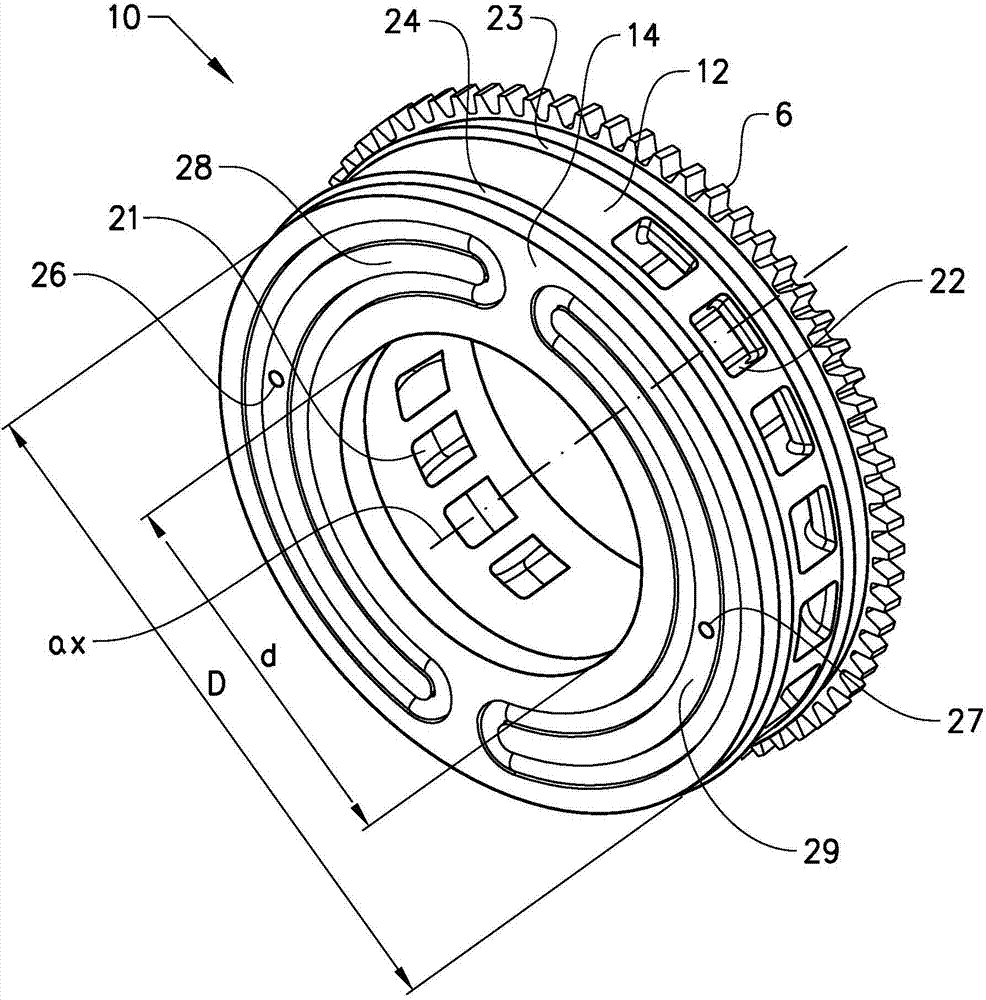

[0028] figure 1 A piston pump 200 is disclosed, in which the control loop 210 of the present invention is arranged. Piston pump 200 is disclosed as a gerotor pump. But the control ring 10, 210 of the present invention is compatible with any piston pump having a fixed pressure chamber. The piston pump 200 includes front and rear housings 101 , 102 , with front and rear plates 103 , 104 of the rotor set 105 arranged therebetween, on which the eccentric shaft 106 of the rotor set 105 and a control ring 210 are mounted. The rotor pack 105 is arranged between a front plate 103 and a rear plate 104, wherein the rear plate 104 is provided with supply ducts to connect the pressure chambers of the rotor pack with inlet 108 and outlet 109 in the rear housing.

[0029] In the illustrated embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com