Delivery pump for cryogenic fuels

A low-temperature fuel and delivery pump technology, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, pumps, etc., can solve the problem of not being able to seal 100%, and achieve the effect of optimizing sealing and reducing fuel volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

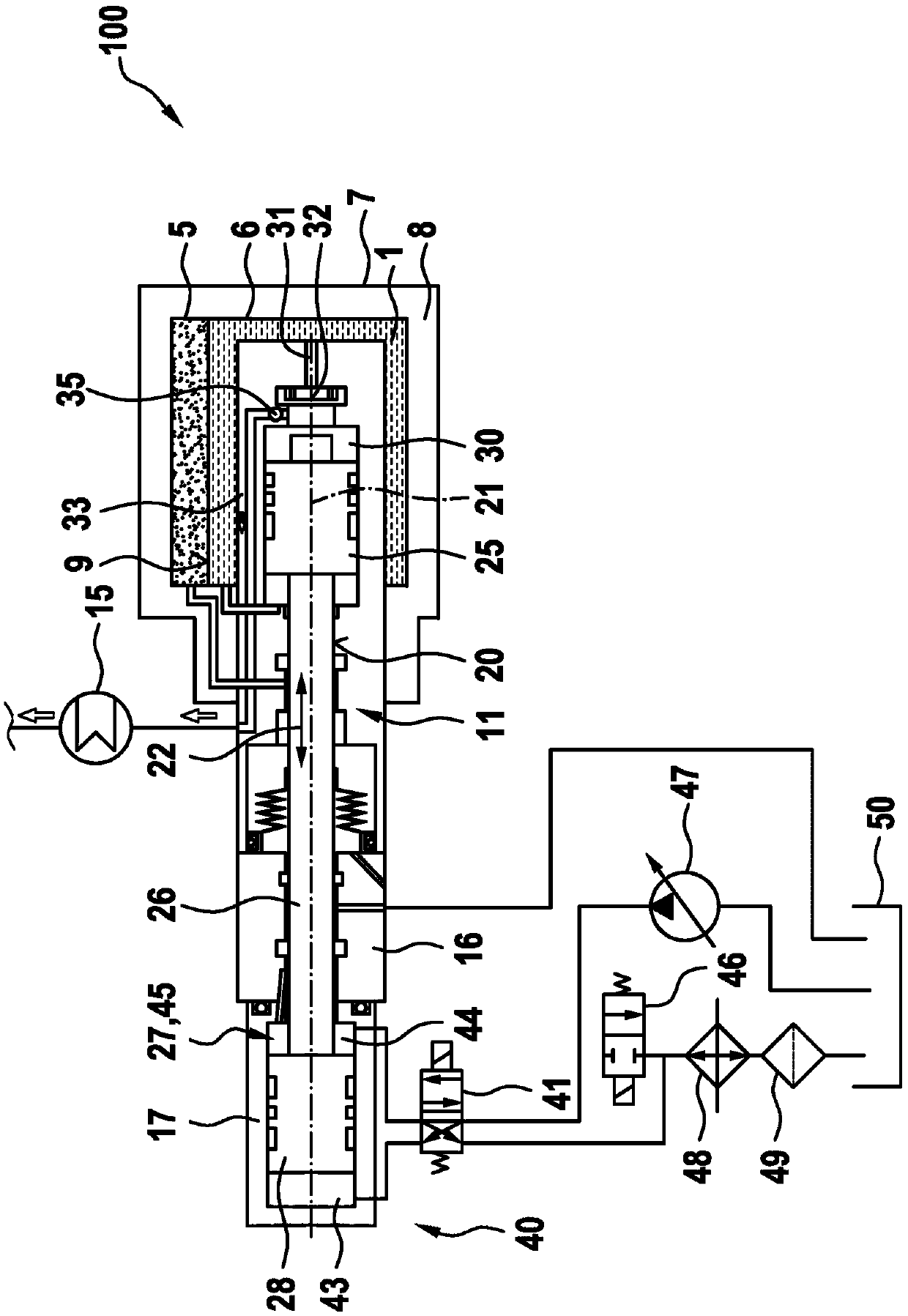

[0019] exist figure 1 A fuel delivery system 100 for cryogenic fuel 1 is shown in . The fuel 1 is in particular natural gas, and the fuel delivery system 100 is preferably used in an internal combustion engine of a motor vehicle.

[0020] The fuel delivery system 100 has a tank-type container 5 for storing fuel 1 cooled to, for example, -110° C. or lower. For this purpose, the box-like container 5 has an inner box 6 which is surrounded by an outer shell 7 in the form of an intermediate chamber 8 . The intermediate chamber 8 is usually evacuated in order to prevent heat transfer or heat input from the surroundings into the cooled fuel 1 . In the tank container 5 , in particular in the inner tank 6 , the liquid part of the fuel 1 reaches the filling level 9 . Above the fill level 9 the fuel 1 is present in the gaseous phase.

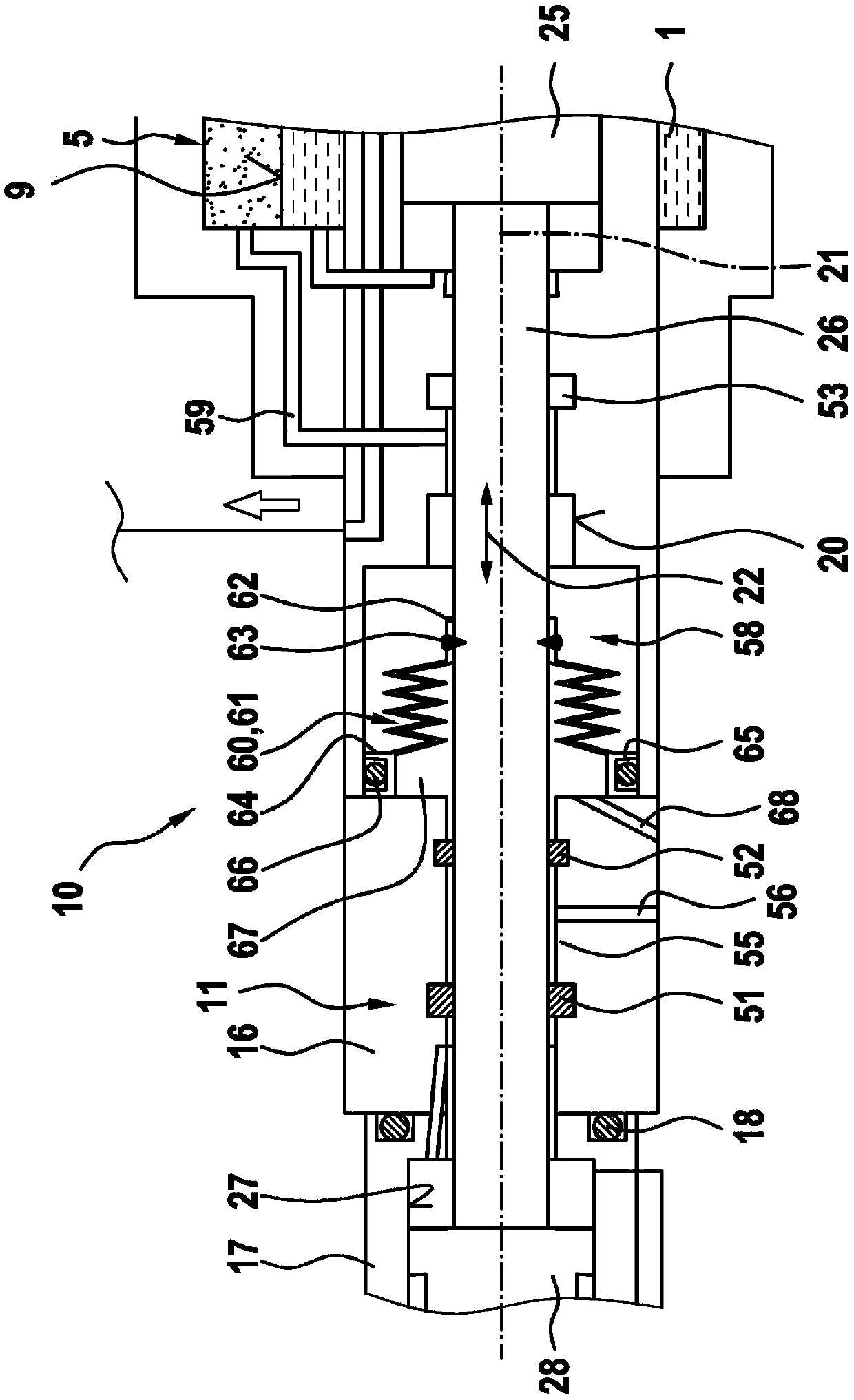

[0021] The tank container 5 , or its inner tank 6 and outer casing 7 , is passed through by a delivery pump 10 which has a pump housing 11 . In the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com