Directly under backlight device

A backlight and direct-type technology, which is applied in the field of direct-type backlight devices, can solve the problems of insufficient brightness, high cost, uneven tube brightness, etc., and achieve the effect of suppressing uneven tube brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

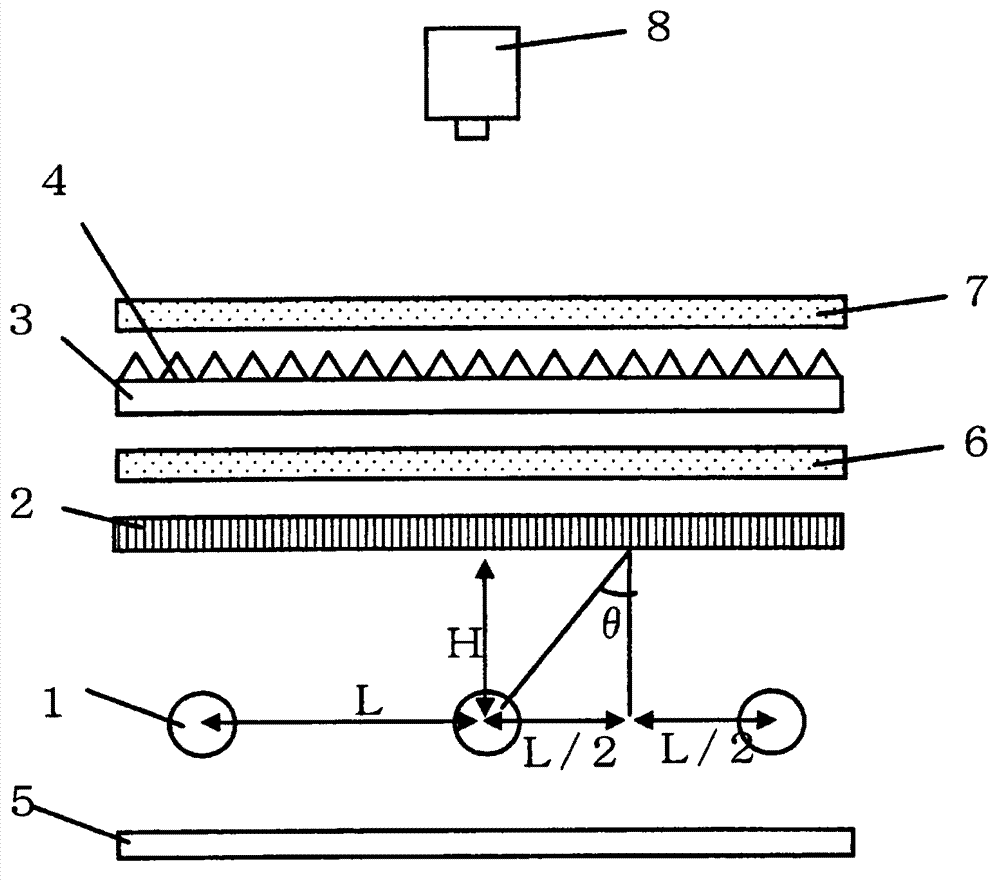

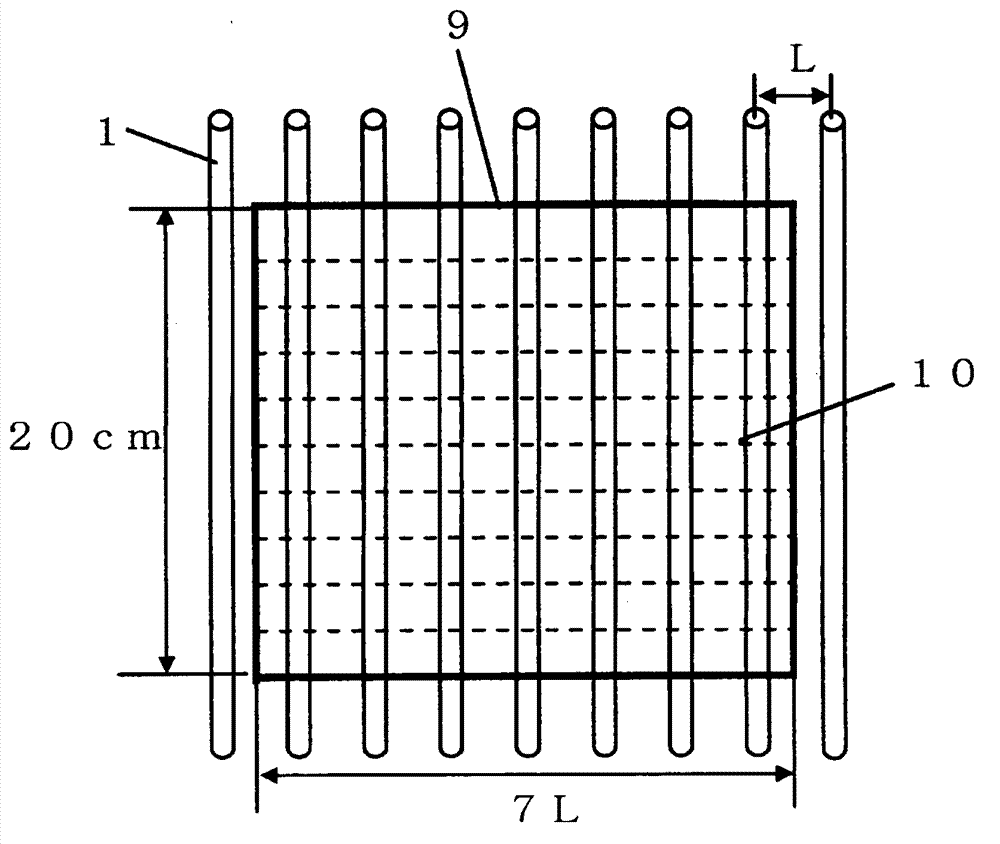

Method used

Image

Examples

Embodiment 1

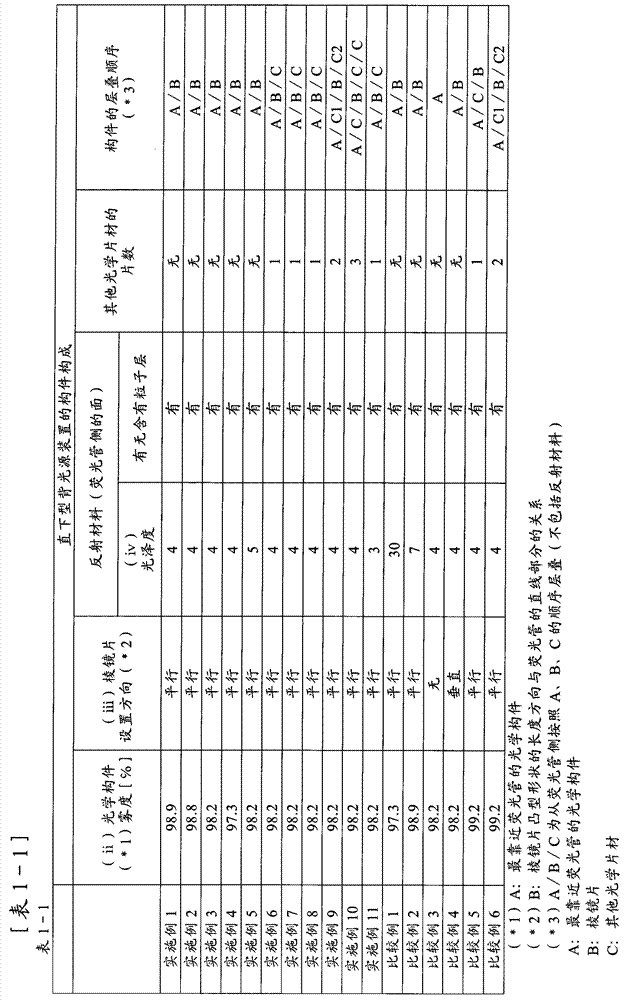

[0138] In the configurations A to D below, the evaluation was performed using the above-mentioned devices 1, 2 and 3.

[0139] A: Clarex (registered trademark) DR-III C-A DR-80C (manufactured by Nitto Plastic Industry Co., Ltd.)

[0140] B: vikuiti BEFIII 90 / 50T (manufactured by 3M Corporation, convex shape: triangle with vertex angles at right angles, pitch of convex shapes: 50 μm) (set in parallel direction)

[0141] C: None

[0142] D: Lumirror (registered trademark) E6QD (manufactured by Toray Co., Ltd., thickness 188 μm)

[0143] Stacking order: A / B.

Embodiment 2

[0145] In the configurations A to D below, the evaluation was performed using the above-mentioned devices 1, 2 and 3.

[0146] A: Sumipex E (registered trademark) RM804S (manufactured by Sumitomo Chemical Co., Ltd.)

[0147] B: vikuiti BEFIII 90 / 50T (manufactured by 3M Corporation, convex shape: triangle with vertex angles at right angles, pitch of convex shapes: 50 μm) (set in parallel direction)

[0148] C: None

[0149] D: Lumirror (registered trademark) E6QD (manufactured by Toray Co., Ltd., thickness 188 μm)

[0150] Stacking order: A / B.

Embodiment 3

[0152] First, a 32-inch LCD TV (manufactured by Hitachi, Ltd., Wooo (registered trademark) UT32-Hv700B), which has a plurality of convex shapes extending in one direction on the surface opposite to the fluorescent tube side, was obtained. A resin plate with a thickness of 2 mm and a convex shape whose longitudinal direction is parallel to the linear direction of the fluorescent tube. For this resin plate, the haze value based on JIS K7136 (2000) when light is incident from the fluorescent tube side at the time of mounting before disassembly is 98.3%, and the incident surface is directly rotated 90° from this state, and measured in the same manner, As a result, the haze value was 98.1%.

[0153] Taking the average value, the haze value of this resin plate was 98.2%.

[0154] Next, after cutting this resin plate into a size that can be installed in the above-mentioned devices 1 to 5 (hereinafter abbreviated as a concave-convex pattern resin plate), evaluation was performed usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com