Pressure sensor calibration method and pressure sensor calibration device

A technology of pressure sensor and calibration method, applied in the direction of measuring device, measuring fluid pressure, instrument, etc., can solve the problems of accurate and reliable value of difficult value, loss of guiding significance for use, etc., to achieve the effect of strong versatility and safe and reliable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

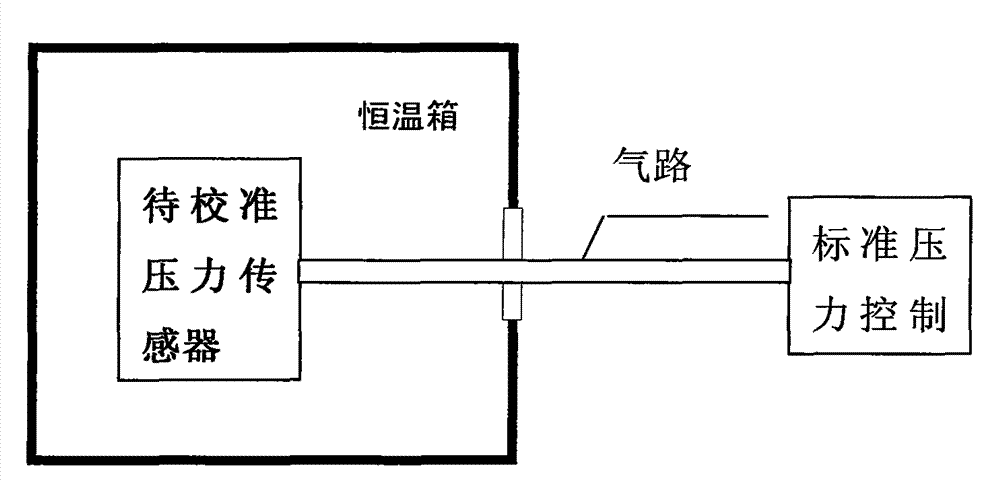

[0031] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not relevant to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

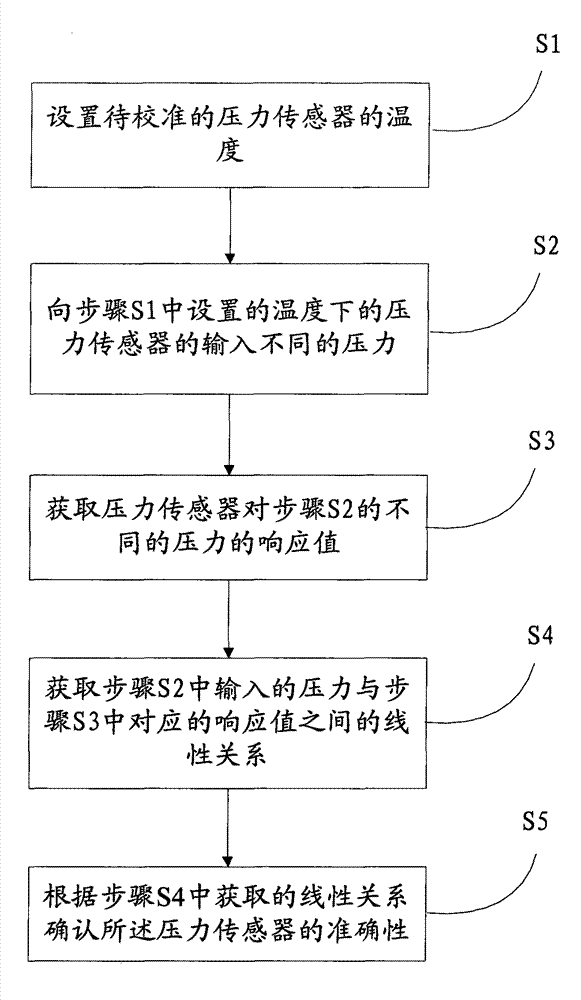

[0032] The invention provides a pressure sensor calibration method, such as figure 1 Shown, be pressure sensor calibration method of the present invention, this method comprises steps:

[0033] S1. Set the temperature of the pressure sensor to be calibrated.

[0034] Due to the large temperature difference of the pressure sensor used in different experimental sites and environmental tests, the staff can set it in combination with the actual work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com