Experimental device for research on rock high temperature thermal rupture under stress effect

A technology of stress action and experimental equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to quantitatively detect the distribution of cracks, destroy rock micro-damage structures, and be expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

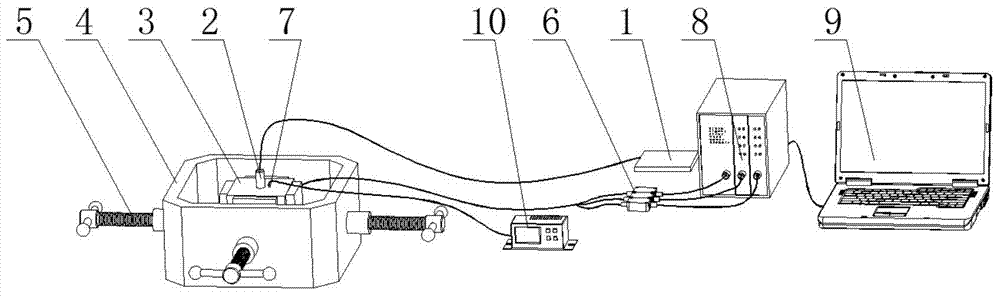

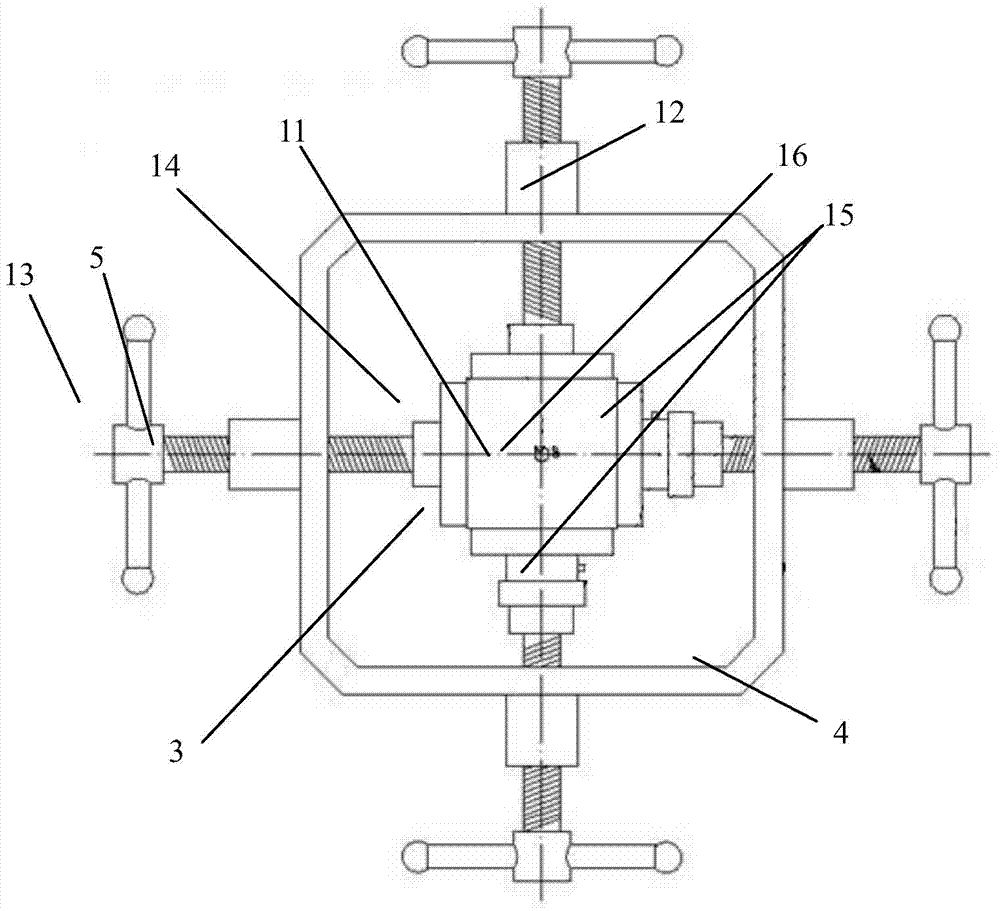

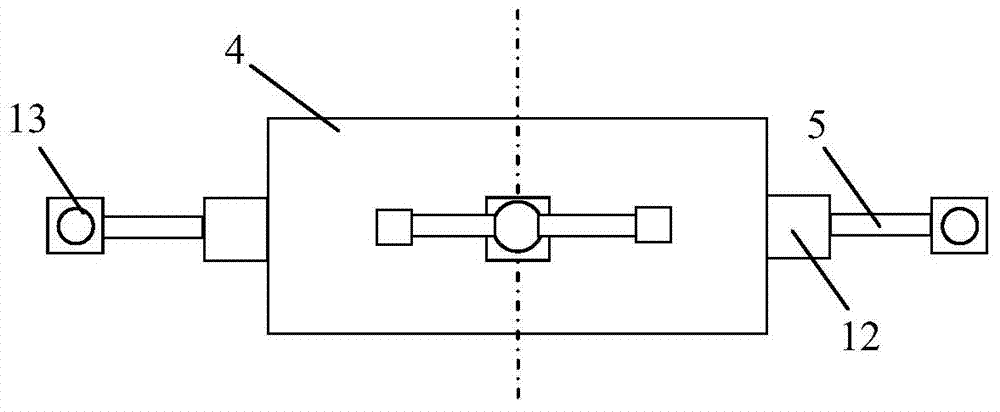

[0017] The experimental device for thermal fracture of rock under high temperature under stress, including heating system, core clamping system, crack detection system and temperature measurement system. The heating system is composed of a power supply 1 and a heating rod 2, one end of the heating rod 2 is connected to the power supply 1, and the other end is inserted into the rock core groove 11 filled with electrolyte to fully heat the rock core; in the rock core clamping system , the rock core 3 is located at the center of the rock core holder 4, applies horizontal stress to the surroundings of the rock core through the screw rod 5 and the jack nut 12 and fixes the rock core to prevent it from loosening. Fixed on the rock core holder 4, there is a steel block gasket 14 between the rock core 3 and the screw rod 5, which is used to ensure uniform stress on the rock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com