Current detecting circuit and feedback control circuit applied to laminated control power supply and power supply

A technology of current detection circuit and control power supply, which is applied in the direction of measuring current/voltage, control/regulation system, measuring device, etc. It can solve the problem of idle waste of current detection device, and achieve the effect of simple circuit and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

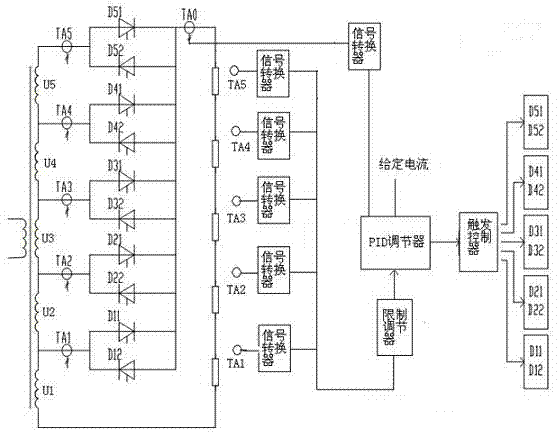

[0028] Embodiment 1: as figure 2 As shown, the purpose of this embodiment is to overcome the problem that at any working time in the prior art, only the current detection devices in two tap branches work at most, causing the current detection devices in the remaining tap branches to be idle and wasteful, and provide a A current detection circuit for a lamination control power supply that greatly reduces the current detection devices in each tap branch, and is used to detect the current when the lamination control power supply is working. The lamination control power supply includes a transformer, and the output terminal of the transformer There are 5 tap branches (the number of transformer taps can be 3, 4, 5, 6, 7 or even more in practical applications), which are respectively the first tap branch U1, the second tap branch U2, The third tap branch U3, the fourth tap branch U4, and the fifth tap branch U5 are used to output voltages of different levels, and each tap branch in...

Embodiment 2

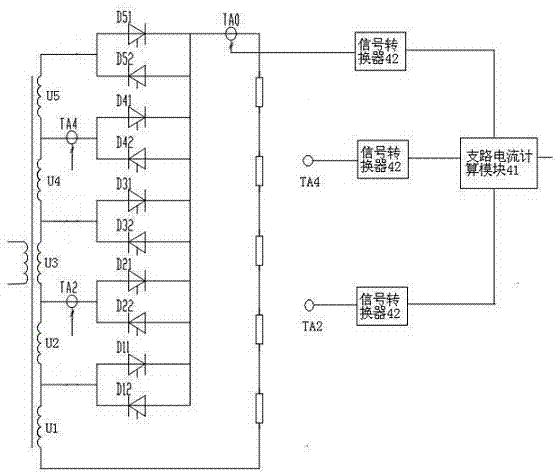

[0041] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that in some embodiments, the branch current detection devices TA2 and TA4 in the second tap branch U2 and the fourth tap branch U4 are connected in series, and,

[0042] Further, the output terminal of the total circuit current detection device TA0 is provided with a signal converter S0, and the output terminals of the two branch current detection devices TA2 and TA4 connected in series are provided with a signal converter S25. This is because only two adjacent tap branches in the laminated control power supply will be put into operation at the same time, and the branch current detection devices set at intervals will never work at the same time, but only one at most will work at the same time state, and in this implementation, the current transformer is used as the current detection device as in Example 1, and the internal resistance of the current transformer is very small, which can be regarded ...

Embodiment 3

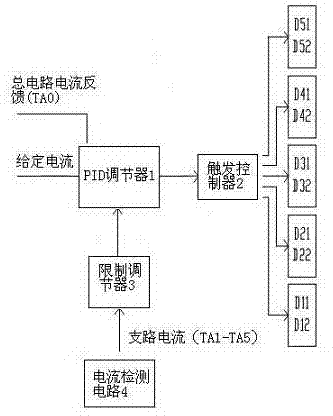

[0044] Embodiment 3: as image 3 As shown, this embodiment provides a feedback control circuit for lamination control power supply using fewer current detection devices, including a PID regulator 1, a trigger controller 2; a limit regulator 3 and The current detection circuit 4 described in Embodiment 2.

[0045] The two input terminals of the PID regulator 1 respectively input the given current and the total circuit detection current output by the total circuit current detection device TA0, the output terminal of the PID regulator 1 is connected with the trigger controller 2, and the output terminal of the trigger controller 2 is connected with the trigger controller 2. The voltage regulators in each tap branch of the laminated control power supply (the voltage regulator in the first tap branch U1 is an anti-parallel thyristor D11, D12, and the voltage regulator in the second tap branch U2 is an anti-parallel thyristor D21, D22, the voltage regulator in the third tap branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com