Display device and pixel circuit and display driving method thereof

A pixel circuit, bias current technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of only light-emitting stage, LCD display driving method without compensation stage, etc., to achieve the effect of fast data input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

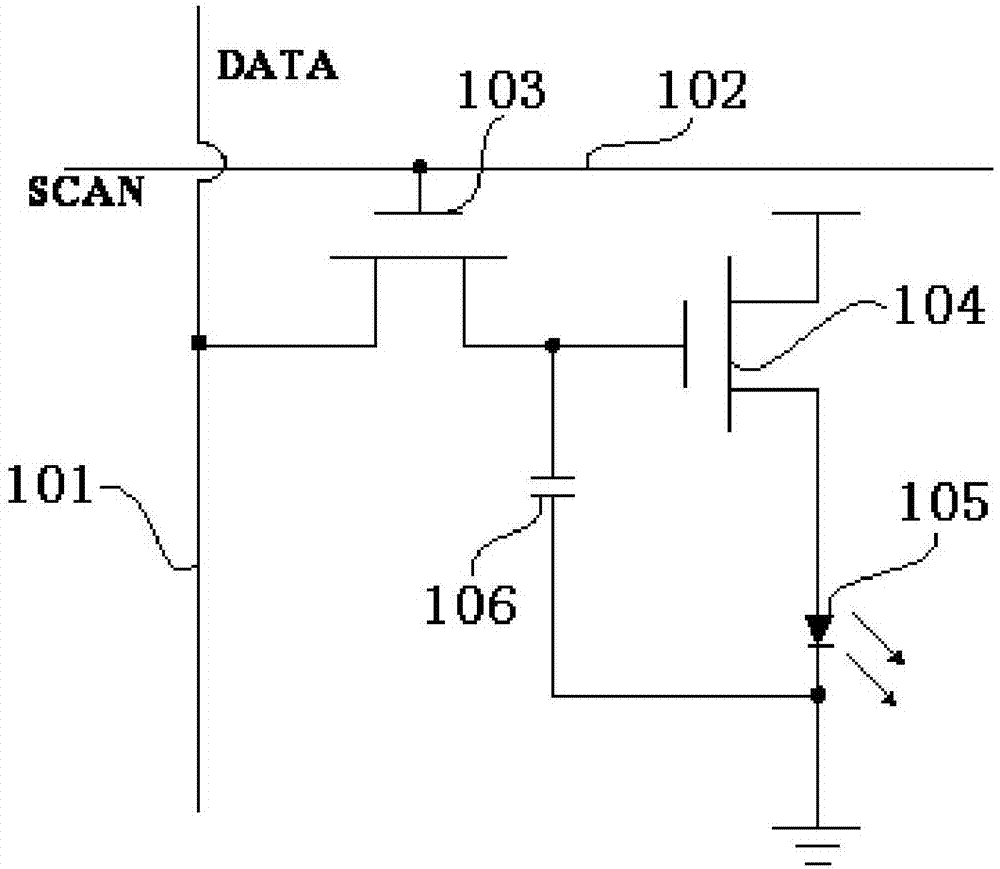

[0052] Please refer to Figure 4 , this embodiment provides a pixel circuit, including a light emitting element 40 , a driving transistor 41 , a first switching transistor 42 , a second switching transistor 43 , a first capacitor 44 and a second capacitor 45 .

[0053] The control electrode of the driving transistor 41 is coupled to the storage node 47 , the first electrode is coupled to the bias current terminal, and the second electrode is coupled to the light emitting element 40 . When the light emitting element 40 is an OLED, the second electrode of the driving transistor 41 is coupled to the anode of the OLED, and the cathode of the OLED is coupled to the common electrode VSS.

[0054] The control electrode of the first switch transistor 42 is coupled to the first scanning signal terminal, the first electrode is coupled to the bias current terminal, and the second electrode is coupled to the storage node 47 .

[0055] The control electrode of the second switch transistor...

Embodiment 2

[0078] Please refer to Figure 7 , this embodiment provides another pixel circuit, including a light emitting element 70 , a driving transistor 71 , a first switching transistor 72 , a second switching transistor 73 , a first capacitor 74 and a second capacitor 75 .

[0079] The control electrode of the driving transistor 71 is coupled to the storage node 77 , the first electrode is coupled to the bias current terminal, and the second electrode is coupled to the light emitting element 70 . When the light emitting element 70 is an OLED, the second electrode of the driving transistor 71 is coupled to the anode of the OLED, and the cathode of the OLED is coupled to the common electrode VSS.

[0080] The control electrode of the first switch transistor 72 is coupled to the first scanning signal terminal, the first electrode is coupled to the bias current terminal, and the second electrode is coupled to the storage node 77 .

[0081] The control electrode of the second switch tran...

Embodiment 3

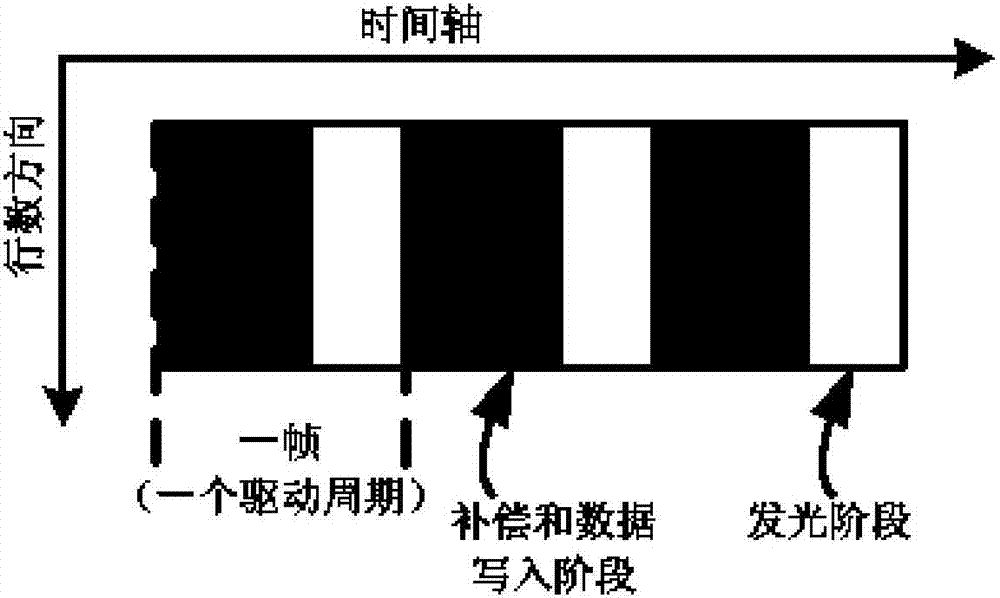

[0102] Please refer to Figure 10 , corresponding to Embodiment 1, this embodiment provides a display device, including a display panel 102 , a data driving circuit 103 and a gate driving circuit 106 .

[0103] The display panel 102 is composed of N*M pixel circuits 101 provided in Embodiment 1 arranged in a matrix, where N is the number of rows of the display panel 102, M is the number of columns of the display panel 102, and M and N are positive integers .

[0104] The data drive circuit 103 includes M bias current lines 104 and M data signal lines 105, and the bias current lines 104 are respectively connected to the bias current terminals of the pixel circuits 101 in each column (that is, the bias current terminals of the same column of pixel circuits are connected to to the same bias current line) for providing bias current and driving voltage to the pixel circuit 101; the data signal line 105 is respectively connected to the data signal end of each column of pixel circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com