A semi-superjunction mosfet structure and manufacturing method thereof

A fabrication method and semi-superjunction technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as process capability limitations, expand application fields, increase trench depth, and achieve high withstand voltage capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

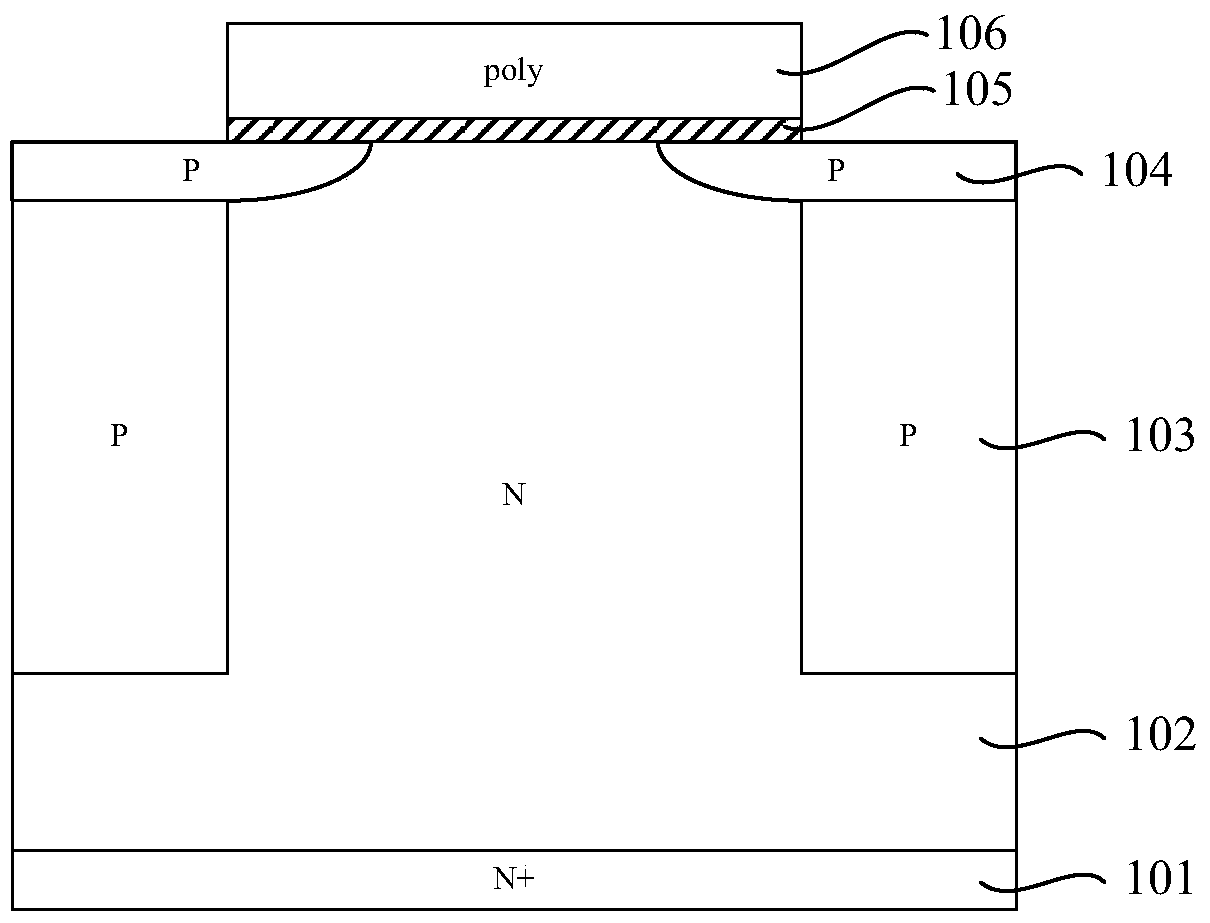

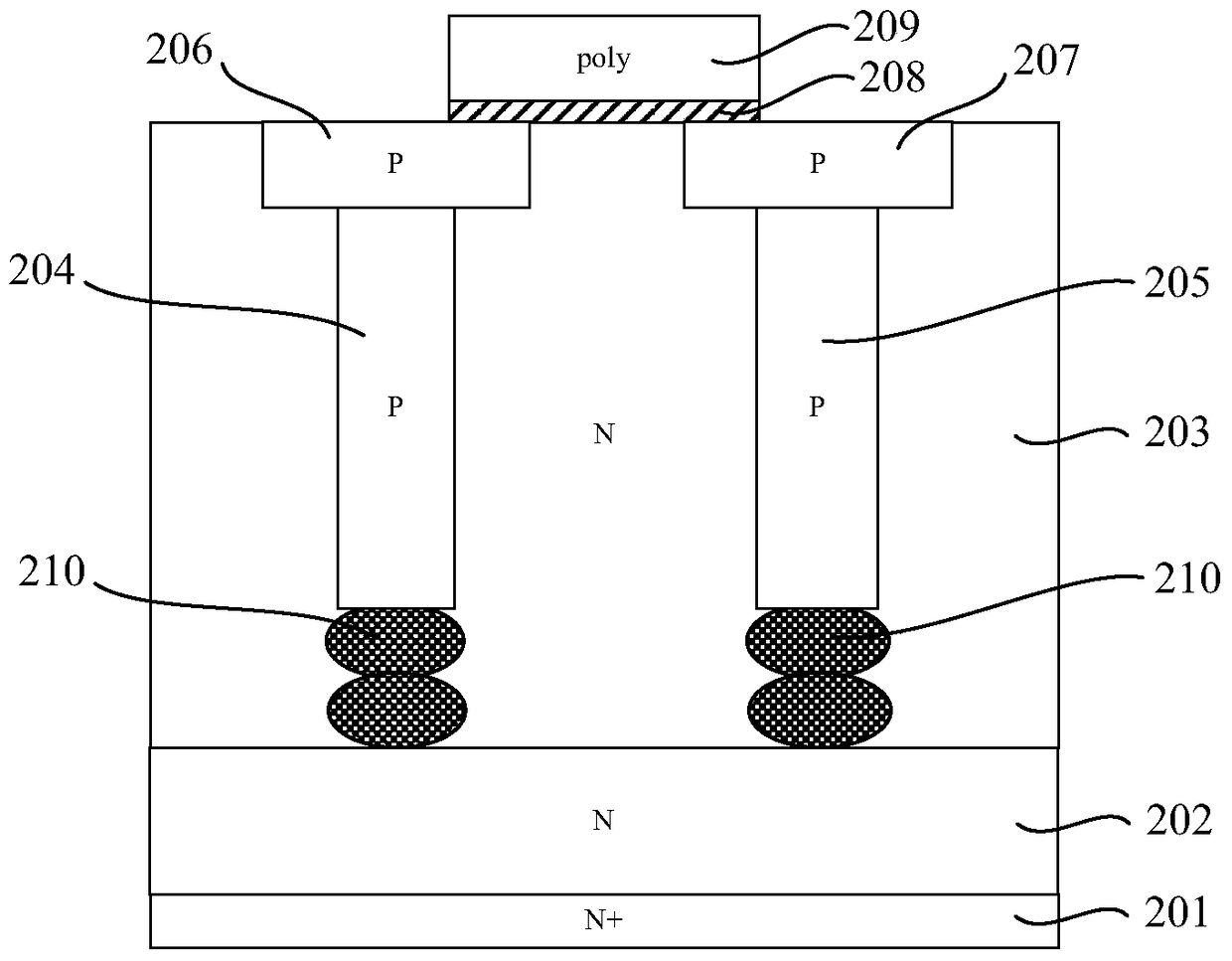

[0076] The present invention provides a semi-superjunction MOSFET structure, please refer to image 3 , shown as a schematic diagram of the structure, comprising at least one transistor cell comprising:

[0077] An N-type heavily doped substrate 201 and an N-type auxiliary layer 202 and an N-type drift layer 203 sequentially formed on the N-type heavily doped substrate 201;

[0078] A first P column 204 and a second P column 205 are formed in the N-type drift layer 203;

[0079] The first P-type body region 206 and the second P-type body region 207 are connected to the tops of the first P-pillar 204 and the second P-pillar 205 respectively, and the first P-type body region 206 and the second P-type body region 207 is located in the N-type drift layer 203;

[0080] A gate structure is formed on the surface of the N-type drift layer 203; the gate structure is located between the first P column 204 and the second P column 205, and both ends of the gate structure are connected t...

Embodiment 2

[0089] The present invention also provides a method for fabricating a semi-superjunction MOSFET structure, comprising the following steps:

[0090] See first Figure 5 , performing step S1: providing a semiconductor substrate sequentially comprising an N-type heavily doped substrate 201 and a first N-type epitaxial layer 215 from bottom to top, and performing P-type impurity implantation on the top of the first N-type epitaxial layer 215 , forming a first pair of P island structures 2101 arranged at intervals. Wherein, the part of the first N-type epitaxial layer 215 below the first pair of P-island structures serves as an N-type auxiliary layer of the semi-superjunction MOSFET.

[0091] then see Figure 6 , performing step S2: forming a second N-type epitaxial layer 216 on the surface of the first N-type epitaxial layer 215, and performing P-type impurity implantation in the second N-type epitaxial layer 216 to form a second pair of P island structure 2102 ; the second pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com