Axial expansion self-compensating device for aero-engine turbine part tester

An aero-engine and component testing technology, which is applied in the expansion compensation device for pipelines, engine testing, jet engine testing, etc., can solve the problems of cumbersome installation and disassembly, limited application scenarios, and low flexibility, so as to improve the service life , widen the application environment and avoid fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

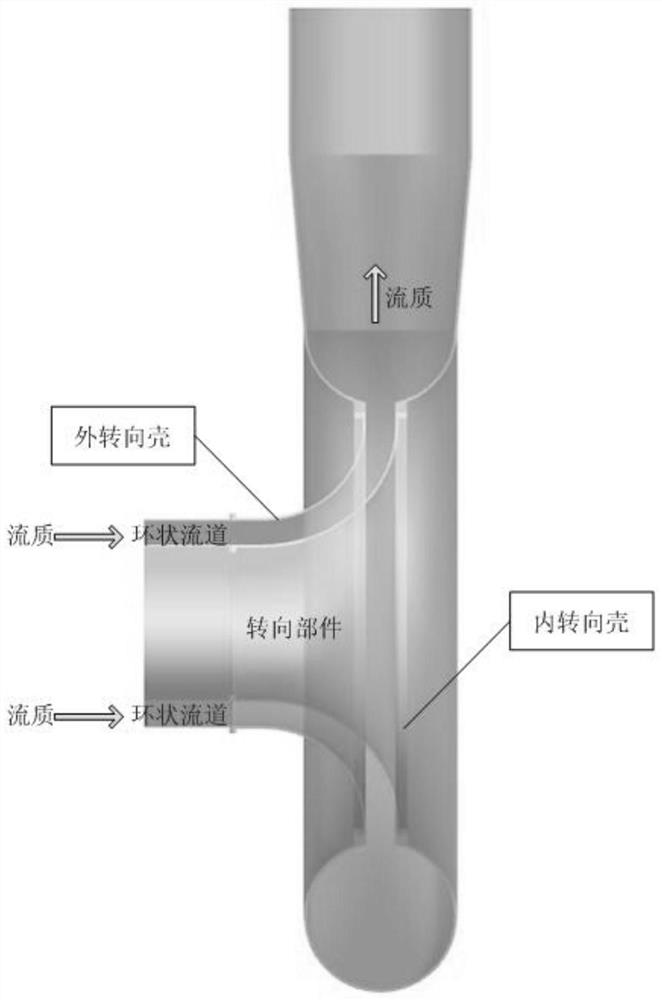

[0025] The turning parts of the annular flow channel generally include two turning sections inside and outside, and the common forms are as figure 1 .

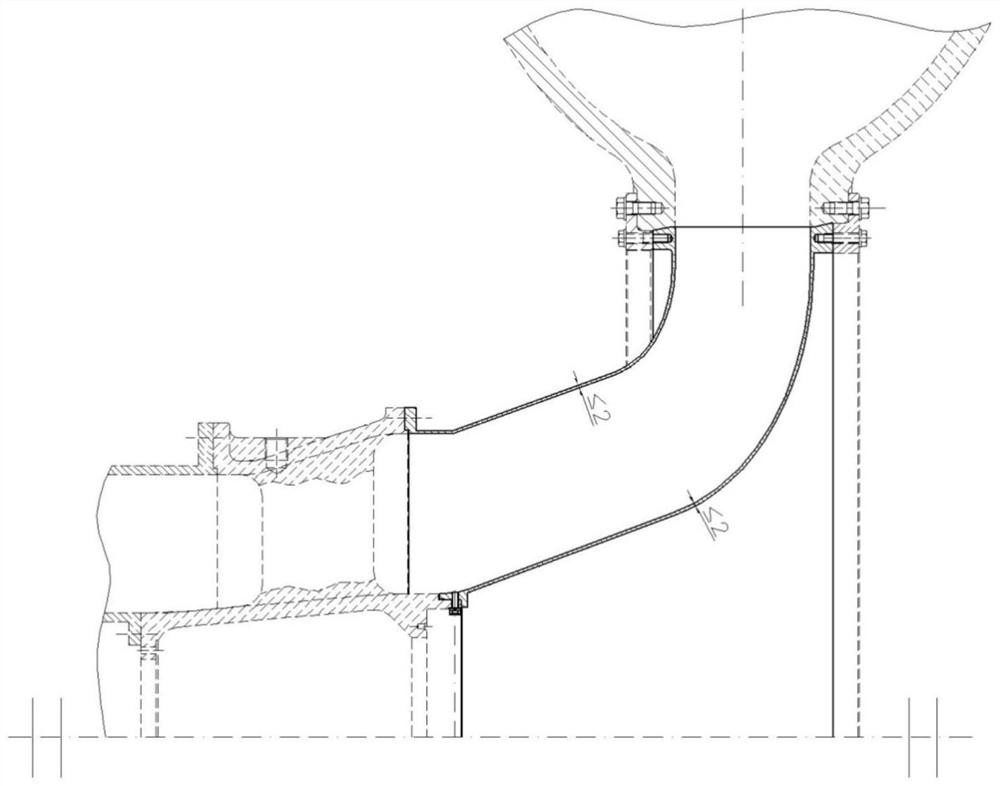

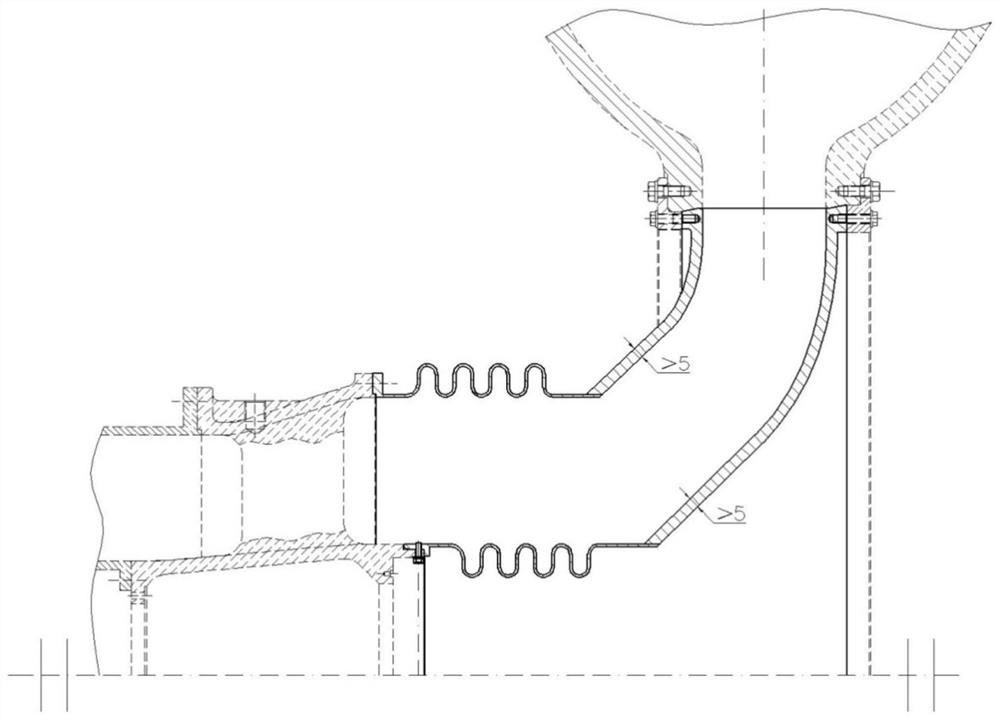

[0026] At present, the popular high-temperature and high-pressure steering parts on the market mainly adopt two methods: one is to use thin-walled steel plates with a wall thickness of no more than 2 mm to weld them, and use the deformation of the thin-walled parts to absorb the axial expansion of the test piece, such as figure 2 shown. The second is to use a thick-walled steel plate with a wall thickness of more than 5mm, and install an expansion joint at the front end of the steering section to absorb the axial expansion of the flow channel, such as image 3 shown.

[0027] figure 2 The main limitation of the structure shown is that due to the use of thin wall parts, the strength of the material limits its use conditions. According to practice, when the fluid pressure is higher than 350kPaA or lower than 20kPaA, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com