End executor of potted vegetable seedling supply mechanical hand

An end-effector and manipulator technology, applied in transplanting machinery, agriculture, applications, etc., can solve the problems of difficulty in timely completion, low efficiency of manual operations for seedling replenishment, inability to take out pot seedlings at the cotyledon stage, etc. The effect of technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

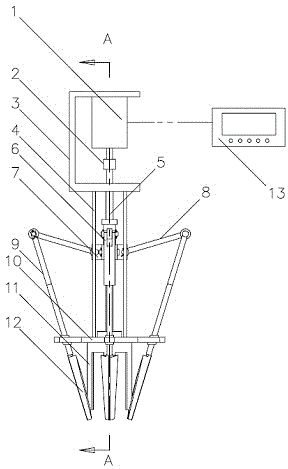

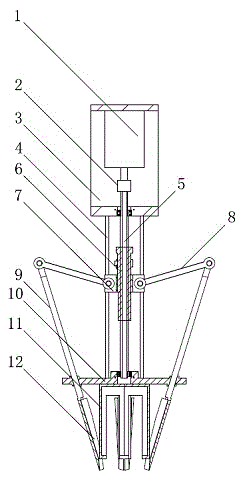

[0014] The product will be further described in conjunction with the accompanying drawings and examples below.

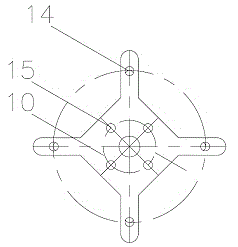

[0015] As shown in the figure, the end effector of the manipulator for potting vegetable seedlings includes a stepping motor 1, a coupling 2, a support plate 3, a support rod 4, a screw rod 5, a spiral sliding sleeve 6, a lifting block 7, a connecting rod 8, Guide rod 9, guide plate 10, seedling removal plate 11, seedling shovel 12, controller 13; support plate 3 is a "U"-shaped structure rotated 90 degrees; lifting block 7 is a "well"-shaped central opening structure, and the lifting block 7 is socketed and fixed on the spiral sliding sleeve 6, and the spiral sliding sleeve 6 forms a spiral fit with the screw rod 5; the lower end of the screw rod 5 is installed on the center of the guide plate 10 through a bearing, and the upper part of the screw rod 5 is installed on the support plate 3 through a bearing The center of the guide plate 10 is evenly provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com