High-elasticity healthcare insole

A high-elasticity and high-elasticity technology, applied in insoles, footwear, soles, etc., can solve the problems of high elasticity and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

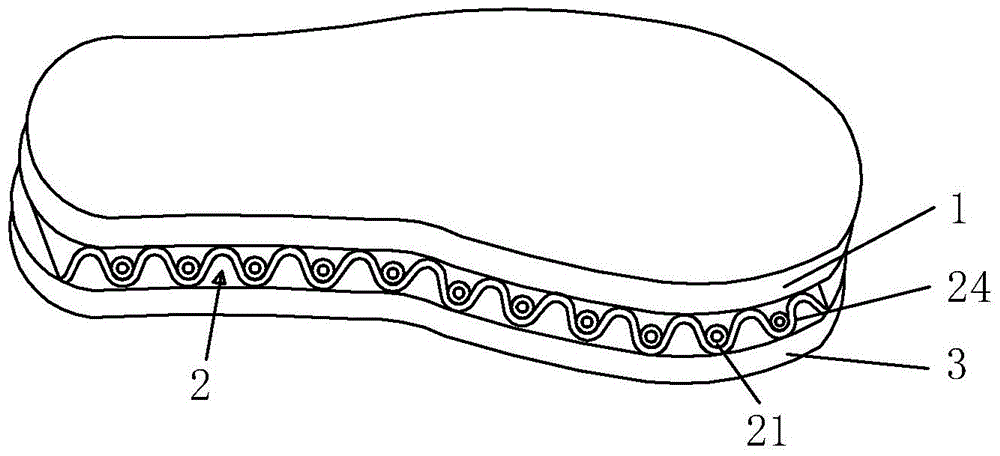

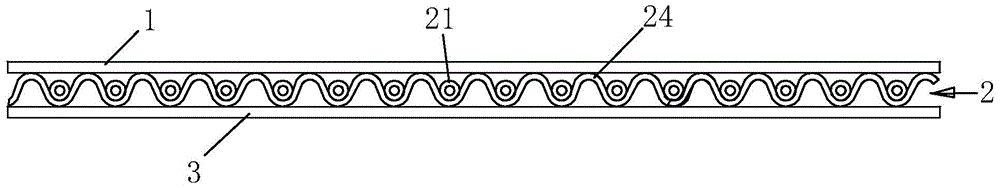

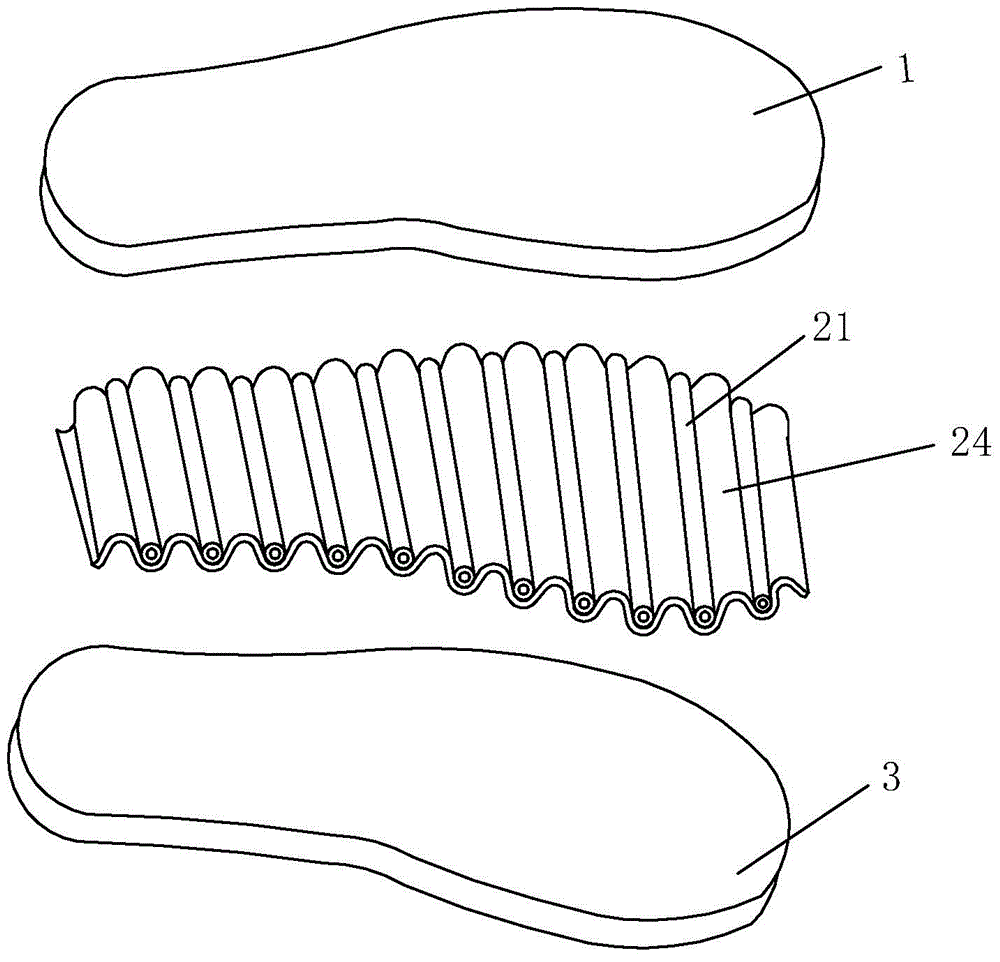

[0057] Such as Figure 1-3As shown, the insole is composed of an upper wear-resistant and breathable layer 1, a lower wear-resistant and breathable layer 3, and a middle highly elastic deformation layer 2. Composite, the heights of the compounded high elastic hose 21 and the wave-shaped high-elastic deformation layer 24 can be the same or different, and the high-elastic hose 21 and the wave-shaped high-elastic deformation layer 24 can be combined by the sum of deformation. Elasticity, with the characteristics of greater elasticity and more comfort.

[0058] The materials used in the upper wear-resistant and breathable layer 1 and the lower wear-resistant and breathable layer 3 include rubber, plastic, silica gel, sponge, woven cloth, real leather, non-woven fabric, synthetic leather, nylon, polyurethane, etc., which are characterized by breathability and wear resistance. The middle highly elastic deformation layer 2 is a key technology, mainly through compound deformation to ...

Embodiment 2

[0062] Such as Figure 10 As shown, it is an improvement to embodiment 1. The improved part is in the middle high elastic deformation layer 2, and the middle high elastic deformation layer 2 is divided into the sole part, the center of the foot and the heel part, and there are wavy high elastic deformations at the sole part and the heel part Layer 24 and high elastic flexible pipe 21, and adopt solid layer 22 at the arch of the foot position, adopt the solid layer 22 to increase the intensity of middle highly elastic deformation layer 2, in addition, the arch of the foot position is not the main position to producing elastic force. Other structures are all the same as in Embodiment 1.

Embodiment 3

[0064] Such as Figure 4-6 As shown, it is an improvement to Example 1, and the improved part is in the middle highly elastic deformation layer 2 .

[0065] The middle high elastic deformation layer 2 only uses the high elastic hose 21 instead of the corrugated high elastic deformation layer 24 . The specific structure is made up of several highly elastic hoses 21 arranged horizontally (if it is not possible to arrange vertically according to the shape of the feet), there is a gap 23 between the high elastic hoses and the high elastic hoses (there is no gap without deformation). 23 is 0.5-1.5 times the outer diameter of the high elastic hose, the gap 23 is related to the amount of deformation, and the amount of deformation is proportional to the elastic force. When the high elastic hose 21 is compressed and flattened, it occupies the space of the gap 23. There is no direct connection between the elastic hose and the highly elastic hose. If there is no gap 23 in the connection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer circle diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com