An aluminum alloy tray

A technology of aluminum alloy and aluminum alloy profiles, applied in rigid containers, containers, packaging, etc., can solve the problems of loose structure, difficult to clean, reduced strength, etc., and achieve the effect of reducing milling, stable structure and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

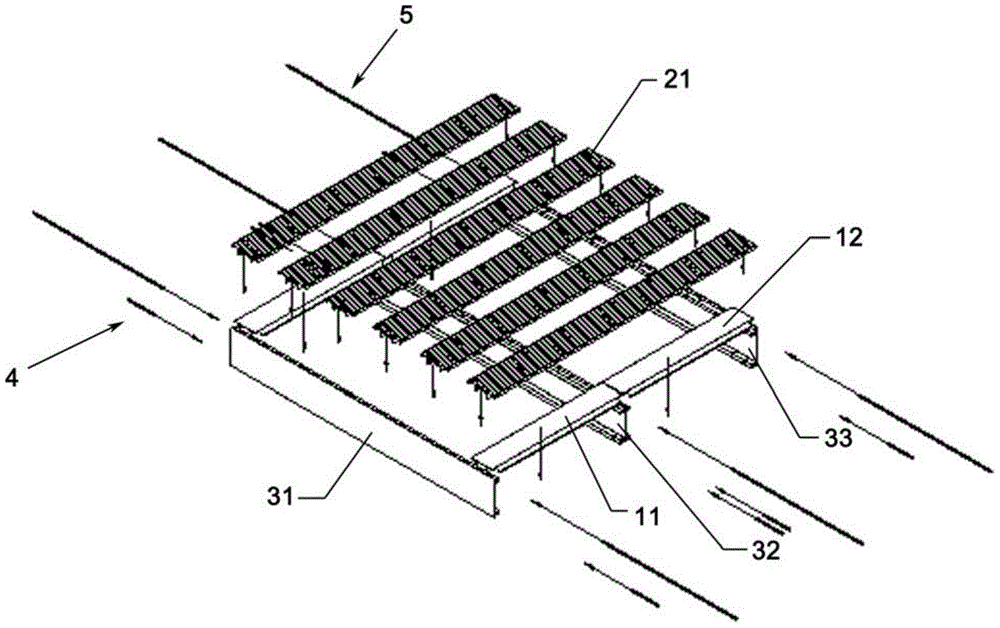

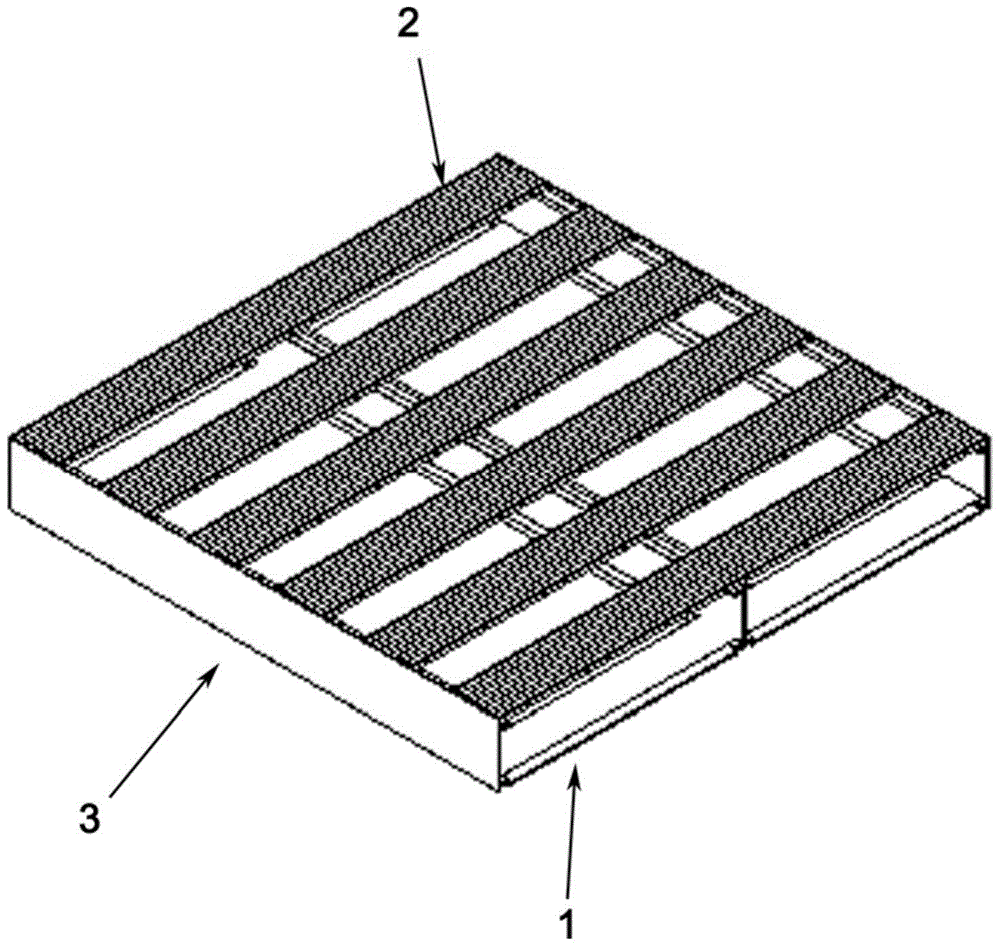

[0031] Such as figure 1 , figure 2 As shown, the present invention discloses an aluminum alloy tray, including a base extending along a first direction made of aluminum alloy profiles, a supporting platform and a connecting portion extending along a second direction perpendicular to the first direction, the connecting portion The lower end and the base, and the upper end of the connection part and the supporting platform are all connected by snap-fitting. There is no need for complicated processes such as welding and bonding, and the aluminum alloy tray can be easily disassembled and assembled only through a simple mechanical structure through a snap-fit method.

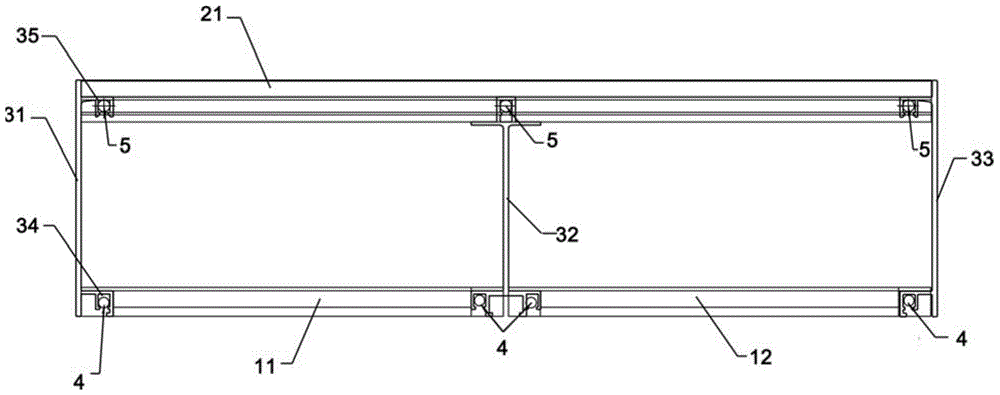

[0032] Such as figure 2 , image 3 , Figure 4 As shown, preferably, the connecting portion includes a first connecting plate, a second connecting plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com