Differential stop device for vehicle

A high-speed, vehicle-use technology, applied in the direction of differential transmission, control device, transmission, etc., can solve the problems of not being able to get enough power from restricted tires, unable to get out of trouble, and unable to achieve on-demand distribution of power, etc. The effect of easy escape of the vehicle, simple structure, high reliability and widening spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

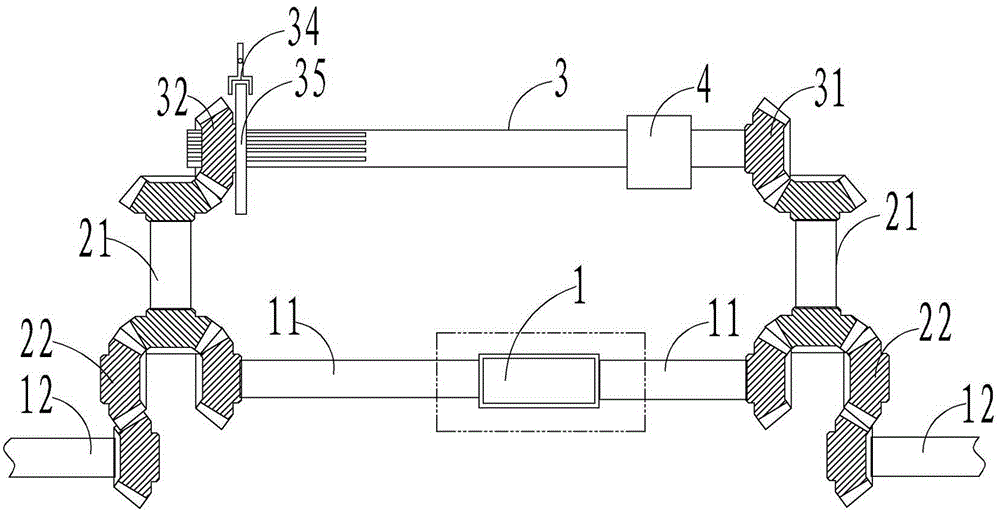

[0064] Embodiment one: if figure 1 As shown, the power output shaft 11 of the differential 1 meshes with the relay gear 22 through the gear at one end of the relay shaft 21, and the wheel shaft 12 meshes with the relay gear 22 after passing through, so that when the synchronous shaft is not working, the power is transmitted by the power The output shaft 11 is transmitted to the wheel shaft 12, and the rotation direction of the wheel shaft 12 is the same as that of the power output shaft 11; the shift fork 34 moves the shift fork piece 35 to move, so that the first interlocking gear 32 approaches the gear at the other end of the relay shaft 21 and After meshing, the two power output shafts 11 of the differential 1 are synchronized, so that the two axles 12 are also synchronized. At this time, the differential is functionally isolated, but power is still being transmitted, but the differential function is locked. ; The clutch 4 on the synchronous shaft 3 is optional and can be o...

Embodiment 2

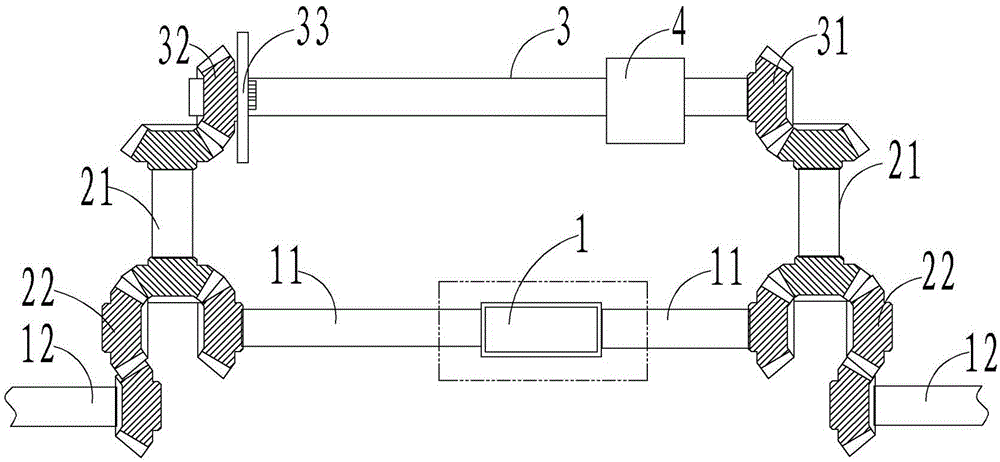

[0065] Embodiment two: if figure 2 As shown, the difference from Embodiment 1 is that the shift fork 34 and the shift fork piece 35 are replaced by a synchronizer 33, so that when the synchronizer is not working, one side of the first linkage gear 32 and the synchronizer 33 are connected to the same side. The wheel shaft 12 is synchronized, the other side of the synchronous shaft 3 and the synchronizer 33 is synchronized with the other side of the wheel shaft 12, and the synchronizer 33 is activated to link the first linkage gear 32 and the synchronous shaft 3 so as to synchronize the two wheel shafts 12. One end of the synchronizer 33 is clamped with the synchronous shaft 3, and the other end is fixedly connected with the first linkage gear 32. When the synchronization device is not started, the two ends (sides) of the synchronizer 33 rotate respectively. After the synchronizer 33 is activated, the linkage gear and the synchronization gear are locked. The shaft 3 achieves th...

Embodiment 3

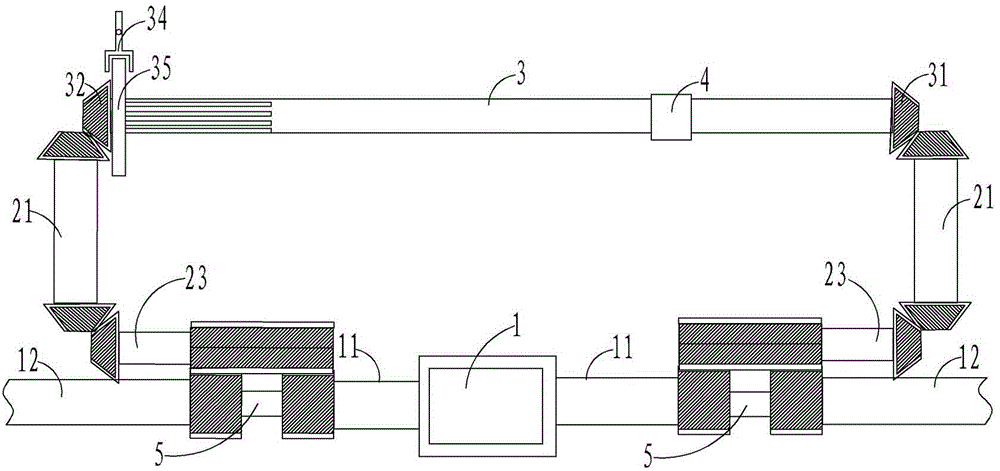

[0066] Embodiment three: as image 3 As shown, the difference from Embodiment 1 is that the wheel shaft 12 and the power output shaft 11 on the same side are meshed at one end of the same branch shaft 5, and the other end of the branch shaft 5 is connected to the second linkage gear of the synchronization device through the relay shaft 21 31 meshes with the first linkage gear 32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com