Waste incineration device

A garbage incineration and garbage technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of unstable combustion temperature, incomplete combustion, environmental pollution, etc., achieve complete and complete combustion, and realize the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a garbage incineration device, which can realize harmless treatment of garbage.

[0024] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

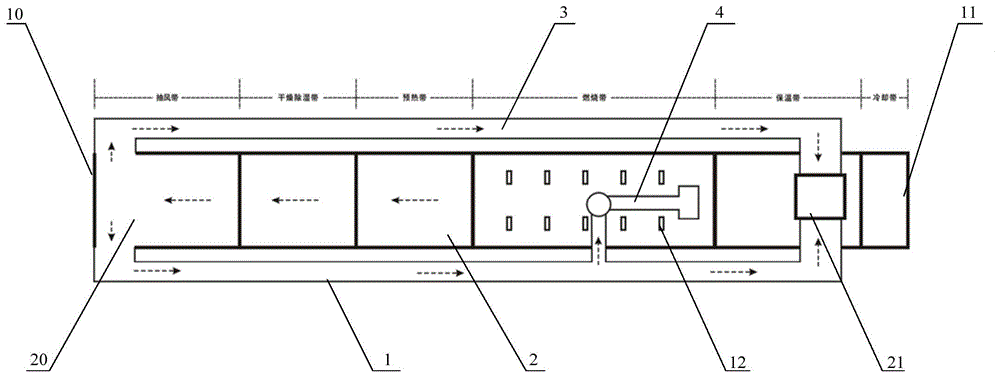

[0025] A garbage incineration device provided by an embodiment of the present invention includes a kiln body;

[0026] There is a furnace chamber in the kiln body along the conveying direction of burnt bricks, and an air duct that communicates with the inlet and outlet of the furnace chamber and surrounds the furnace chamber;

[0027] The kiln body is also provided with a fan that drives the air in the furnace cavity to flow from the outlet to the inlet, and further drives into the air duct;

[0028] The kiln body is provided with garbage drop holes corresponding to the high temperature section of the furnace cavity.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com