Pressure and quantity adjustable air jet type pulverized coal conveying fuel booster for rotary spiral conveyer

A technology of screw conveying and air jet flow, applied in the direction of fuel supply, combustion method, combustion equipment, etc., can solve the problems of reducing the combustion rate, unfavorable air circulation, and not reaching the maximum combustion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

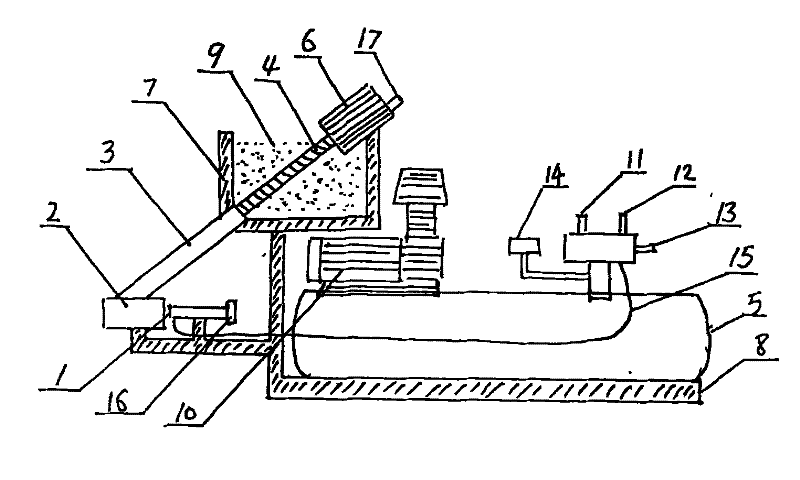

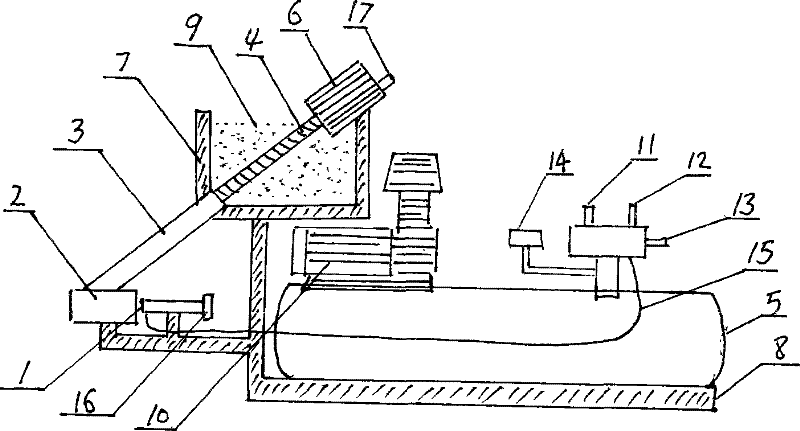

Image

Examples

Embodiment Construction

[0006] This fuel booster is suitable for burning coal on dry powder surface, and consists of a fuel tank, a rotating screw, a speed-regulating motor, a feeding pipe, a throat cavity, a nozzle, and an air pump. The rotating screw is driven by the matching speed-regulating motor to uniformly deliver the fuel from the fuel tank to the throat cavity through the delivery pipe. The flour is sprayed into the furnace in the form of mist, and burns rapidly and fully within 0-1 second. The so-called adjustable: coal burning volume, air injection volume, air pressure, similar to the preheating tool fuel blowtorch used by mechanics in northern my country in winter, this booster can change the flame shape by adjusting the air injection volume, air pressure, and coal burning volume when in use , so as to achieve the best effect.

[0007] The fuel booster is an independent mechanical device, which injects fuel into the furnace or stove for full combustion without changing the structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com