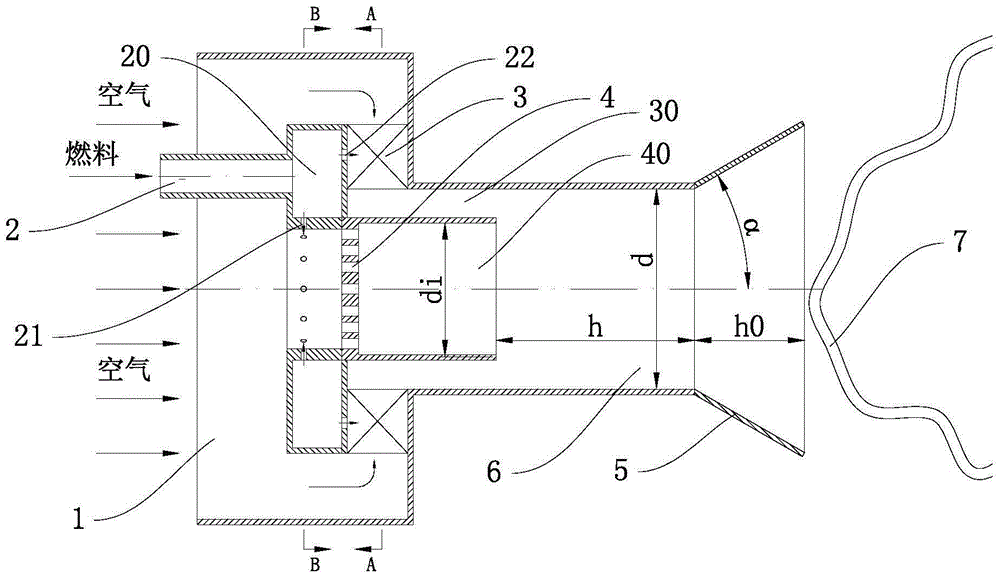

A low-swirl premix nozzle for a low-pollution combustor of a gas turbine

A technology of gas turbines and premixing nozzles, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as large flow resistance, achieve the effects of small flow resistance loss, reduce emissions, and increase flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

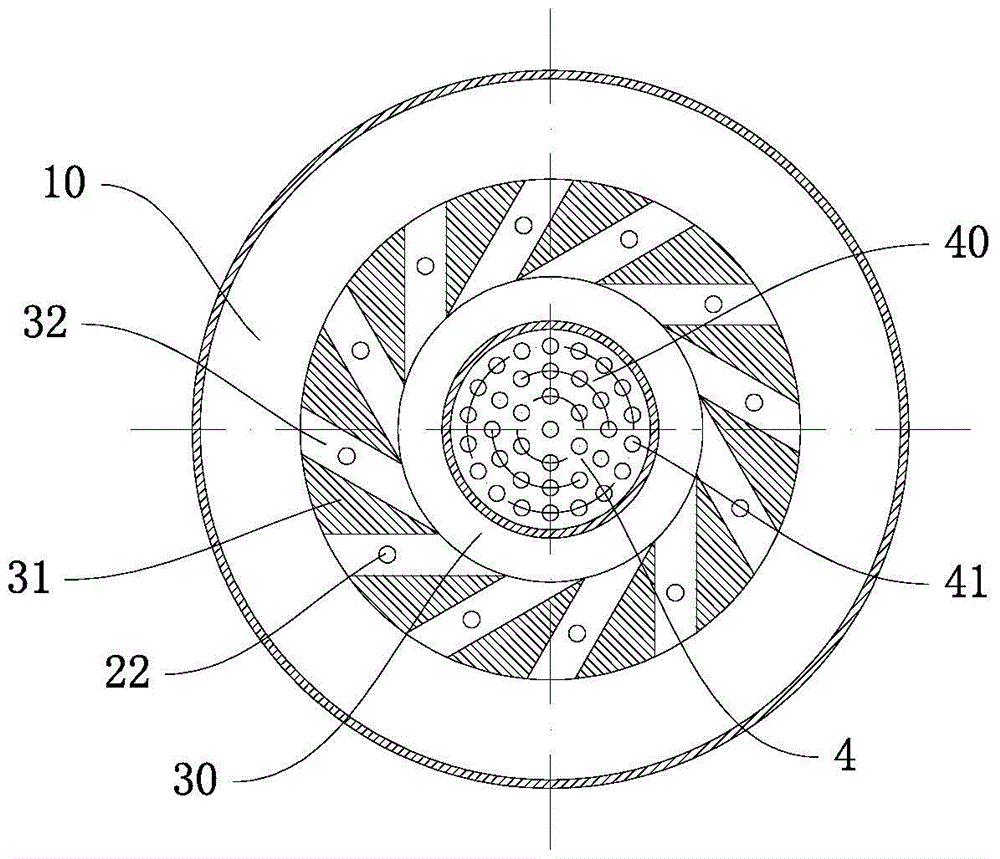

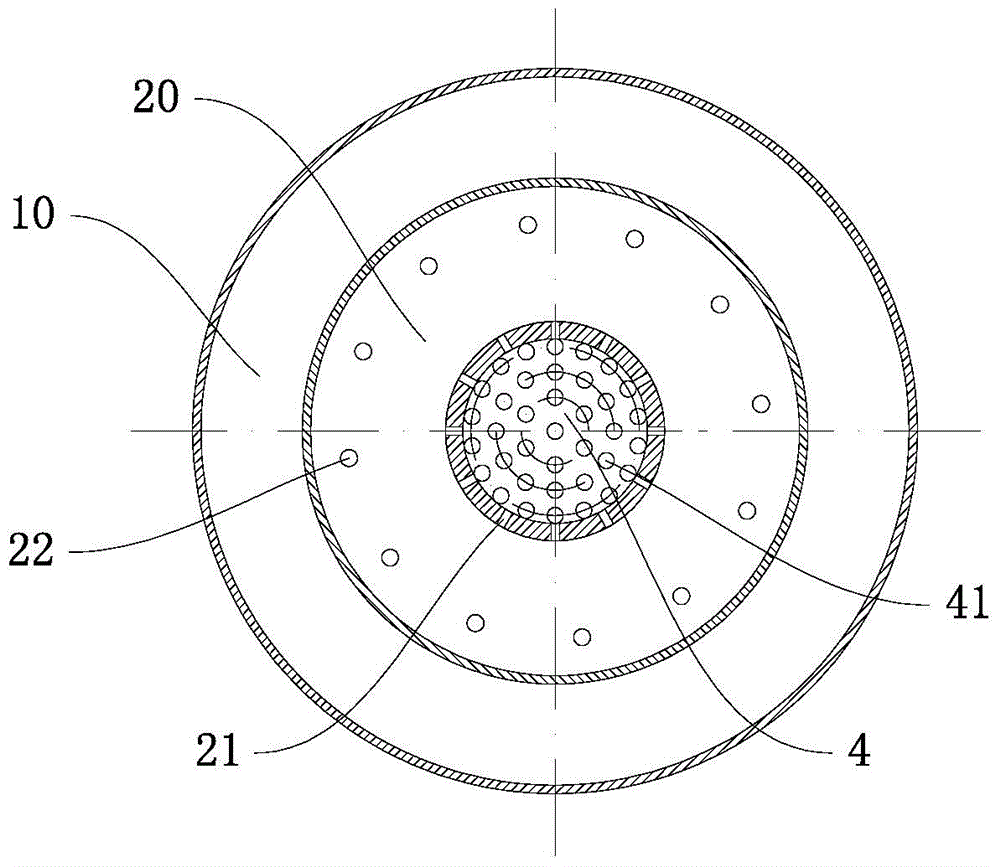

Method used

Image

Examples

Embodiment

[0028] Such as Figure 4 As shown, in the actual gas turbine combustor, an annular or tubular multi-nozzle arrangement structure with nozzles close to each other is usually adopted. The multi-nozzle structure can not only increase the heat load and load regulation ratio of the combustion chamber, but also ensure that when one nozzle is extinguished, the adjacent nozzles can re-ignite it to maintain a stable flame. As shown in the figure, in the specific arrangement, the low-swirl nozzle of the present invention can be used according to the structure of the actual gas turbine to form a gas turbine combustor with a multi-nozzle structure. The central nozzle is the on-duty nozzle 9; the outer side is the low-swirl nozzle 8 of the present invention, the nozzles are evenly arranged along the axial direction of the central nozzle, and the number of the outer nozzles is 4-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com