micro sample cell

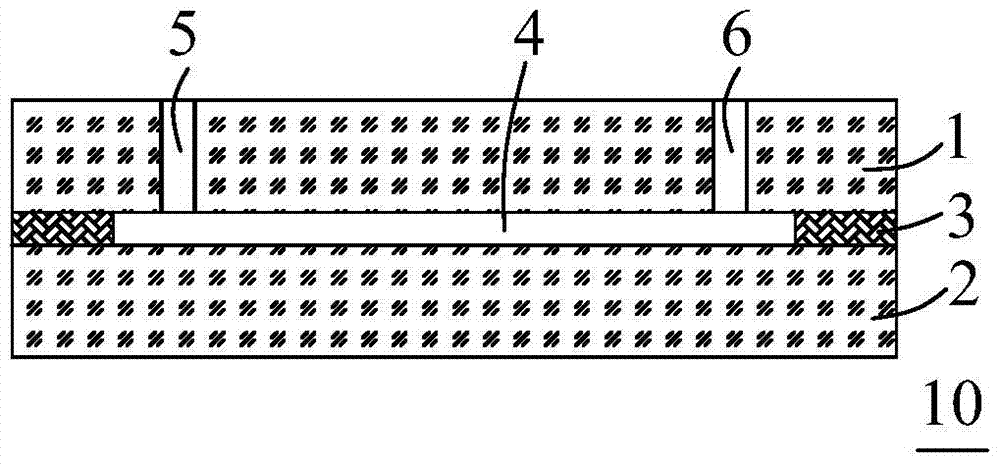

A kind of sample pool and trace technology, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inaccuracy of sample detection, increase the difficulty of cleaning, etc., to prevent detachment, small accommodating space, and easy disassembly. and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

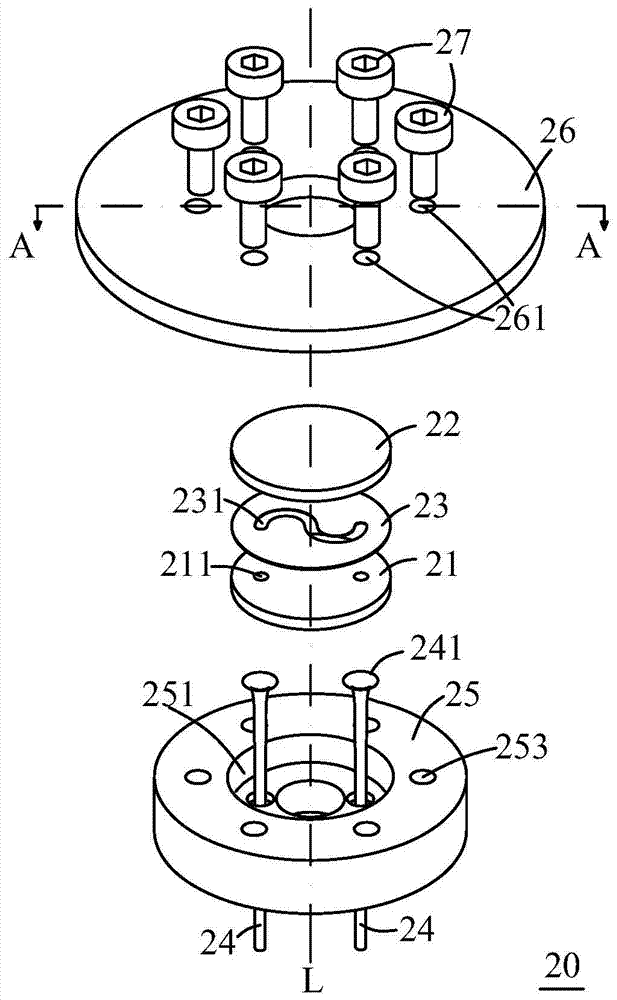

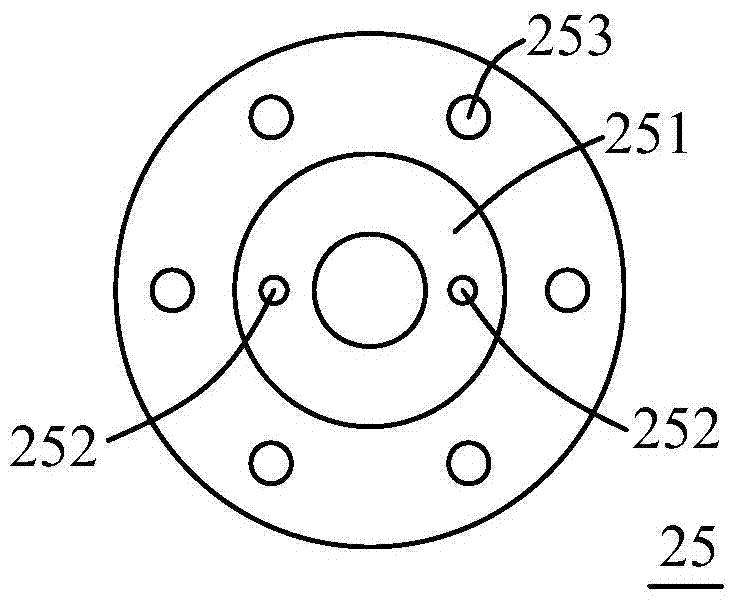

[0028] figure 2 is an exploded view of the micro sample cell according to the first embodiment of the present invention. Such as figure 2 As shown, the micro sample cell 20 includes a glass plate 21 , a glass plate 22 , a guide plate 23 , a guide tube 24 , a holding member 25 and a fixed cover 26 .

[0029] The glass plates 21, 22 are light-transmitting glass sheets with smooth surfaces made of calcium fluoride. There are two through holes 211 on the glass plate 21 . The deflector 23 located in the middle of the glass plates 21, 22 is a thin sheet made of polytetrafluoroethylene with a thickness of about 100 microns. The two smooth surfaces of the guide sheet 23 can make it closely adhere to the glass plates 21 , 22 . The guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com