Under-pressure LNG flash experimental method

An experimental method and flash evaporation technology, applied in the investigation phase/state change and other directions, can solve the problems of jet fire, shortage, and high LNG storage pressure, and achieve the effects of reducing gasification loss, automatic data collection, and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

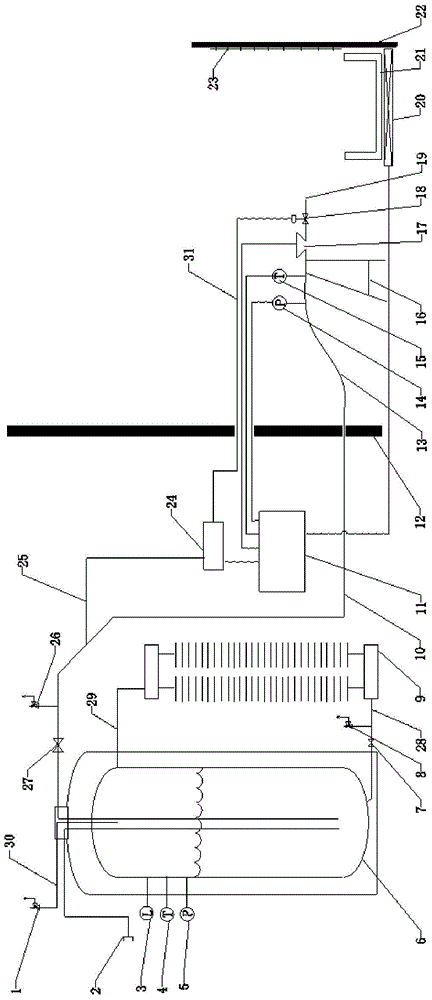

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0047] combine figure 1 As shown, the pressurized LNG flash experiment platform includes LNG storage and pressure regulating delivery device, LNG injection experiment device, measurement control device and safety protection device. in,

[0048] The LNG storage and pressure regulating delivery device is used to realize the storage of LNG, the regulation of pressure, and the delivery of LNG.

[0049] Specifically, the LNG storage pressure regulating delivery device includes an LNG storage tank 6 , a forced vaporizer 9 and a first LNG delivery pipeline 10 . The first LNG delivery pipeline 10 is made of low-temperature heat-insulating material.

[0050] An LNG storage tank filling pipeline 2 is connected to the LNG storage tank 6 for injecting LNG into the LNG storage tank. One end of the liquid filling pipeline 2 for the LNG storage tank is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com