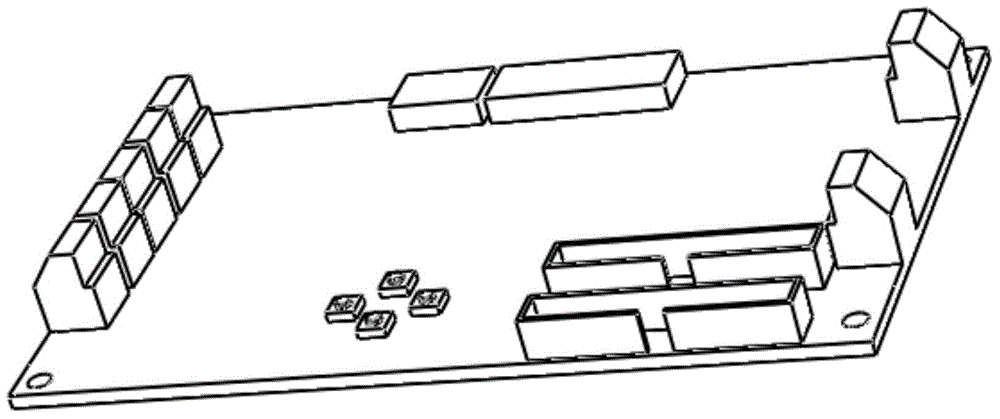

Test device for measuring plates for distributors of photovoltaic header boxes

A photovoltaic combiner box and testing device technology, which is applied in the direction of measuring devices, measuring electrical variables, and electronic circuit testing, can solve the problems of low efficiency and complex structure of the testing device, and achieve the goal of improving test efficiency, improving safety, and simplifying the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

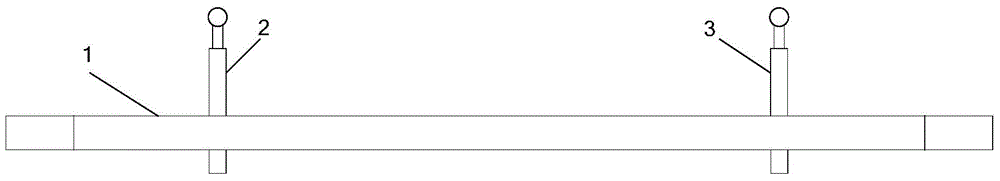

[0025] Such as figure 2 As shown, the test device of the present embodiment includes a base 1, an input test probe 2 and an output test probe 3, the input test probe and the output test probe are vertically fixed on the base, and the upper end of the input test probe is connected to the test probe to be measured. The bottom interface of the input terminal of the board is mated and inserted, the upper end of the output test probe is matched with the bottom interface of the output terminal of the board to be measured, the lower end of the input test probe and the output test probe are connected to the measurement wire, the input test probe and the output test probe The installation position of the needle matches the position of the input and output terminals of the board to be measured.

[0026] During the test, connect the interface at the bottom of the terminal of the board to be measured with the corresponding test probe, and plug the board to be measured into the test probe...

Embodiment 2

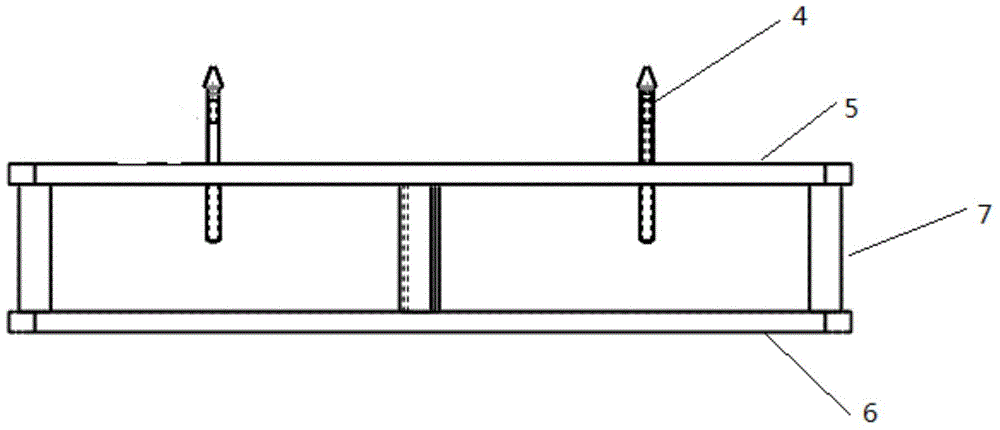

[0029] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, and the part that differs from it is: in this embodiment, a positioning probe 4 for accurately docking the measurement board is arranged on the base 1, and the installation position of the positioning probe is related to the measurement The mounting holes of the board correspond to each other, and at least two positioning probes are installed, and positioning probes are installed on both sides of the measurement board, and the number of positioning probes on both sides is not limited.

[0030] In addition, in this embodiment, the base is composed of upper and lower insulating panels 5, 6 and insulating pillars 7, and the insulating pillars are supported between the upper and lower insulating panels so that a certain gap is formed between the upper and lower insulating panels. Place the test leads connected to the test probes between the upper and lower insulation panels, so that the operat...

Embodiment 3

[0033] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 2. The difference is that the base adopts the structure of a layer of insulating panel. At this time, the test probes are inserted on the base, including the part located on the upper side of the insulating panel and the part located on the insulating panel. The part on the lower side of the panel, where the test probes are located on the lower side of the insulating panel, is connected with the measuring wires, so that the metal conductive part is located on the lower side of the plexiglass plate, which can prevent the wires from being exposed outside, thereby preventing the tester from Accidental electric shock accidents can also protect the personal safety of testers.

[0034] In addition, in this embodiment, an unlocking baffle 9 and a rack buckle 8 are arranged on the upper insulating panel of the base, and the unlocking baffle and the rack buckle here are used to fix the measuring boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com