Electric connector and manufacturing method thereof

A technology for electrical connectors and manufacturing methods, which is applied to multiple injection molding electrical connectors and its manufacturing field, can solve the problems of inconvenient operation, many steps, and high manual assembly costs, and achieve simple manufacturing methods, low stamping difficulty, The effect of convenient injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

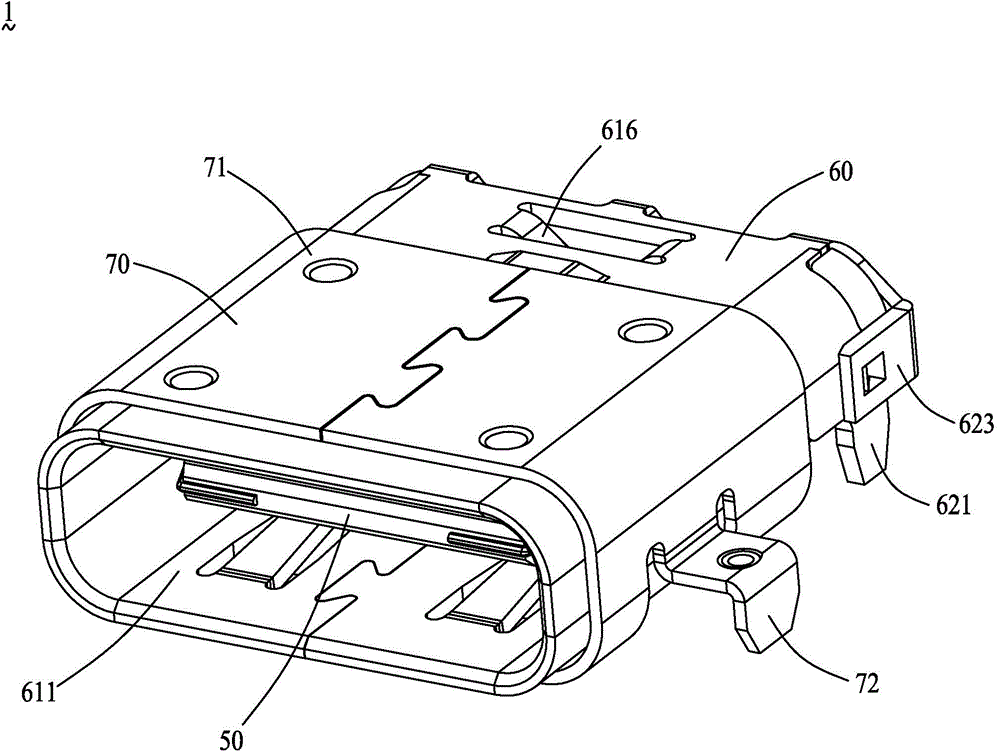

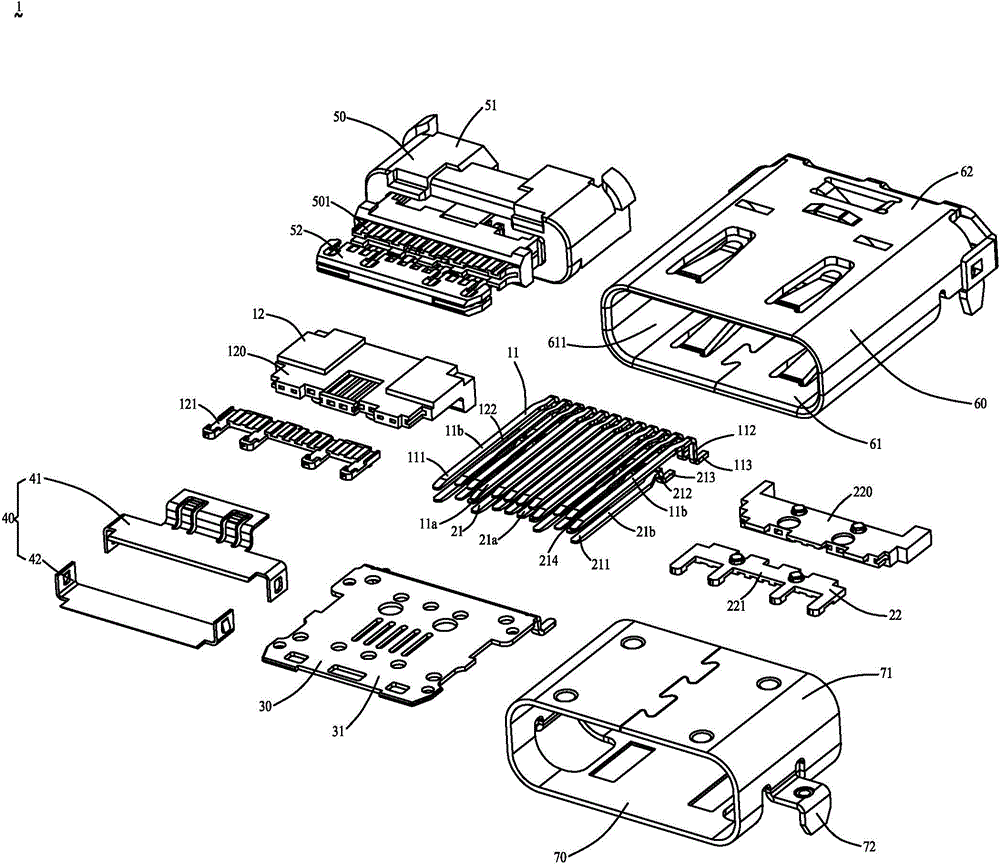

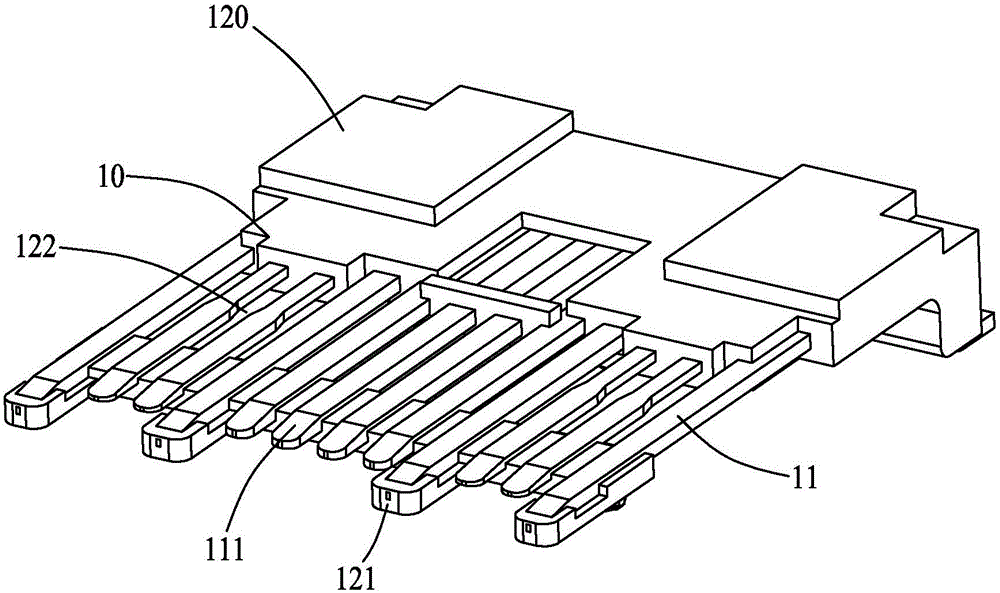

[0043] see Figure 1 to Figure 13 As shown, the electrical connector 1 of the present invention can be installed on an external circuit board (not shown) and can be mated with a mating connector (not shown). The electrical connector 1 includes an upper row of terminal assemblies 10, a lower row of terminal assemblies 20, a grounding piece 30 located between the upper row of terminal assemblies 10 and the lower row of terminal assemblies 20, injection molded on the upper row of terminal assemblies 10 and the lower row of terminals. The outer insulator 50 on the outside of the assembly 20, the inner metal shell 40 and the outer shell 60 fixed on the outer side of the outer insulator 50, and the waterproof shell 70 sleeved on the outer shell 60 to pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com