Acoustical waterproof structure

A waterproof structure and acoustic technology, applied to transducers used underwater, can solve problems such as high cost, low output sound pressure, and difficulty in meeting high waterproof levels, and achieve the effect of preventing water from entering the inner cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

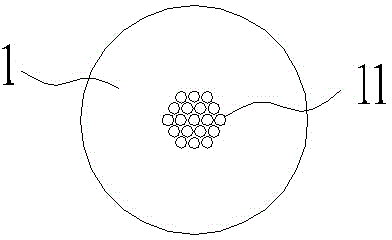

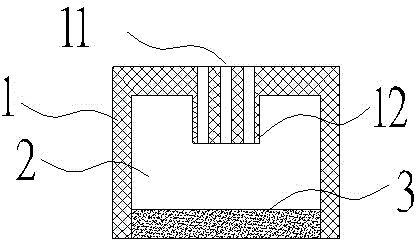

[0015] refer to figure 1 with figure 2 As shown, an acoustic waterproof structure includes an acoustic cavity main body 1 , an acoustic cavity 2 and a closed sound source 3 in the rear cavity.

[0016] Further, the acoustic cavity main body 1 is provided with an array of microholes 11 and a microhole sound guide post 12 .

[0017] Further, the acoustic cavity 2 is closed.

[0018] Further, the array of micro-holes 11 and the micro-hole sound guide post 12 form a breathable and waterproof array of micro-sound holes.

[0019] Principle of the present invention:

[0020] When working, the closed sound source 3 in the back cavity produces original audio vibrations, and the sound signal is amplified after the resonance of the sound cavity 2, and then emitted by the breathable and waterproof array micro-sound holes composed of the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com