Heat-sensitive ceramic heater assembly and its heater and mounting bracket

A technology of heat-sensitive ceramics and mounting brackets, applied in electric heating devices, heating elements, shapes of heating elements, etc., can solve the problems of no insulation fixation, easy to be pulled out, low safety, etc., to achieve convenient maintenance and high-quality thermal conductivity. , combined with a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

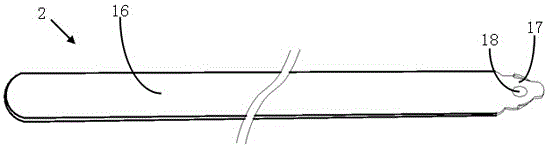

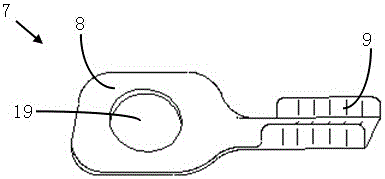

[0060] A heat-sensitive ceramic heater, the heat-sensitive ceramic heater includes a heating part and a mounting bracket composed of a heating strip and a connecting wire group, the heating strip includes a set of heating cores and two layers combined with the heating plane of the heating cores The radiator, the heating core includes heat-sensitive ceramic heating sheet 1, electrode sheet 2 and insulating paper 3, the insulating paper 3 tightly wraps the electrode sheet 2 and the heating sheet 1 clamped in the middle, the radiator It includes a heat conduction pipe body 4 and a heat dissipation fin 5, the heat dissipation fin 5 is combined on the heat dissipation surface 6 of the heat conduction pipe body 4, the joint portion of the covering surface of the insulating paper 3 is located on the non-heat conduction surface on the side of the thickness of the heating core, There is a connection piece 7 between the power lead-out surface of the heating strip and the connecting line ...

Embodiment 2

[0065]A heat-sensitive ceramic heater, the heat-sensitive ceramic heater includes a heating part and a mounting bracket composed of a heating strip and a connecting wire group, the heating strip includes two sets of heating cores and four layers combined with the heating plane of the heating core The radiator, the heating core includes heat-sensitive ceramic heating sheet 1, electrode sheet 2 and insulating paper 3, the insulating paper 3 tightly wraps the electrode sheet 2 and the heating sheet 1 clamped in the middle, the radiator It includes a heat conduction pipe body 4 and a heat dissipation fin 5, the heat dissipation fin 5 is combined on the heat dissipation surface 6 of the heat conduction pipe body 4, the joint portion of the covering surface of the insulating paper 3 is located on the non-heat conduction surface on the side of the thickness of the heating core, There is a connection piece 7 between the power lead-out surface of the heating strip and the connecting lin...

Embodiment 3

[0070] A mounting bracket for a heat-sensitive ceramic heater, the mounting bracket has a base body 12 and a cover plate 13, the upper end of the base body 12 is open, there are several small cavities inside, and the end portion has an outwardly extending mounting surface 21. There is a mounting hole 22 on the mounting surface 21 that is docked with the complete machine. The outer wall of the end of the base body 12 has an arc-shaped through hole 14 that can accommodate and lead out the power connection line. The upper part of the base body 12 There is a cover plate 13 on the end surface, and the side surfaces of the seat body 12 and the cover plate 13 are provided with docking, fixing and positioning devices for connection and adaptation.

[0071] The docking, fixing and positioning device includes two first positioning through holes 23 for connecting and fixing the heater and the cover plate 13 .

[0072] On both sides of the cover plate 13, there are first connecting surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com