Mitigation of Vapor Cloud Explosions by Chemical Suppression

A vapor cloud explosion and inhibitor technology, applied in the field of mitigating vapor cloud explosion through chemical suppression, can solve problems such as destruction and explosion equipment, and achieve the effects of reducing consequences, reliable methods, and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

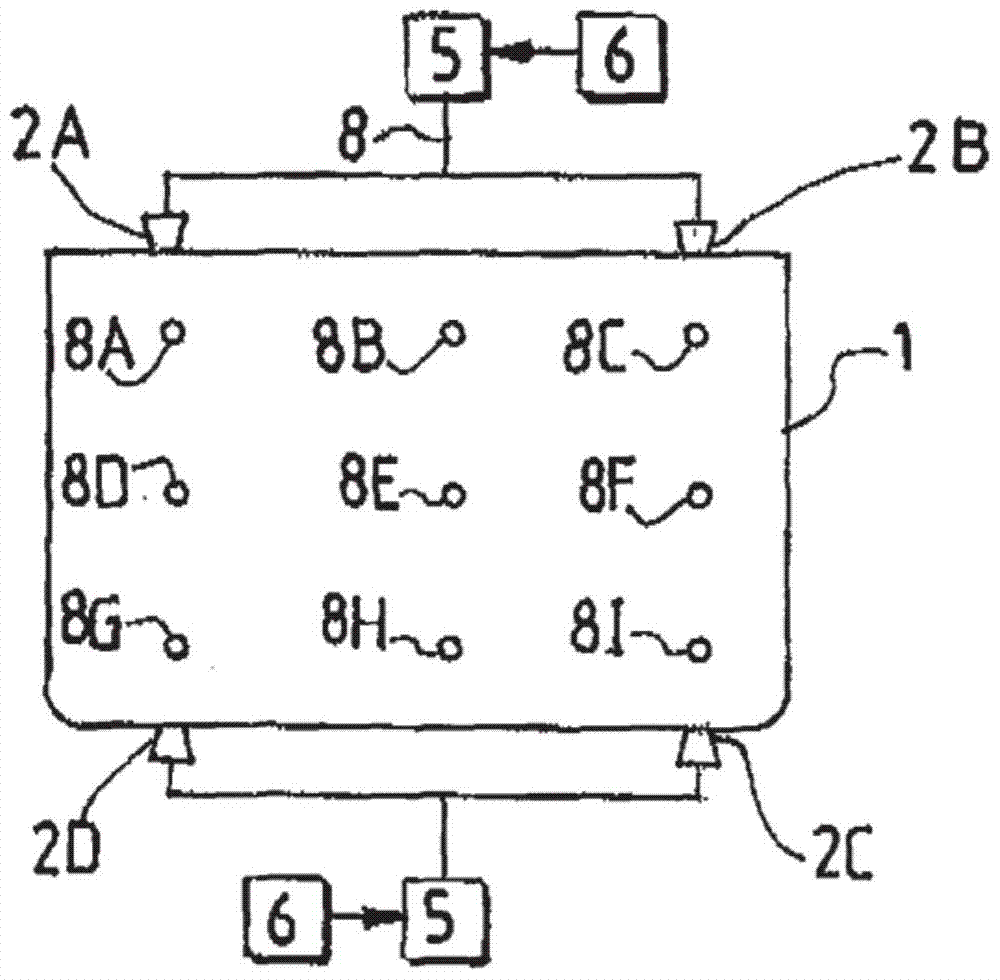

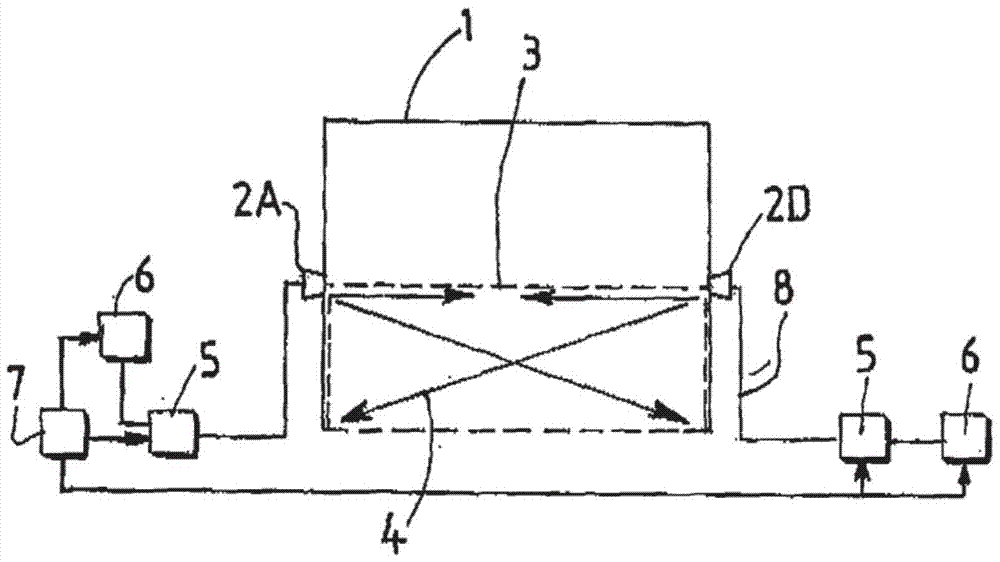

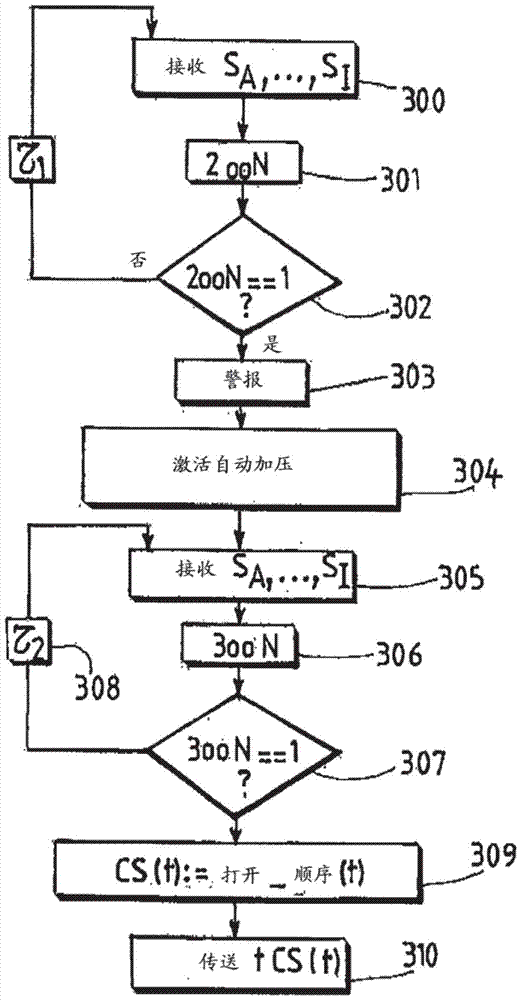

[0116] Where flammable gases are present include utilities, chemical and petrochemical manufacturing plants, petroleum refineries, metallurgical industries, breweries, paint and varnish manufacturing, offshore operations, printing, semiconductor manufacturing, pharmaceutical manufacturing, and aerosol can filling operations Processed as a raw material, product or by-product in many industrial applications, including In addition, flammable gases are released through leaks in above-ground or underground piping systems or leaks of flammable liquids. The present invention is very attractive for refineries and petrochemical plants.

[0117] A refinery can consist of multiple units.

[0118] The invention can be applied, for example, to three units of an oil refinery, eg, steam cracker unit, butadiene separation unit, aromatics unit, etc.

[0119] Each unit has been divided into several processing areas. Each unit can have, for example, 1 to 4 processing zones.

[0120] Each pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com