A poppet valve with a surface-modified surface of the valve head using a ni-cr-co-based alloy with high-temperature corrosion resistance

一种耐高温腐蚀、表面改性的技术,应用在升阀、阀细节、阀装置等方向,能够解决涂敷层破裂、热冲击抵抗性低、剥离等问题,达到优秀高温腐蚀耐性、提高耐高温腐蚀特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

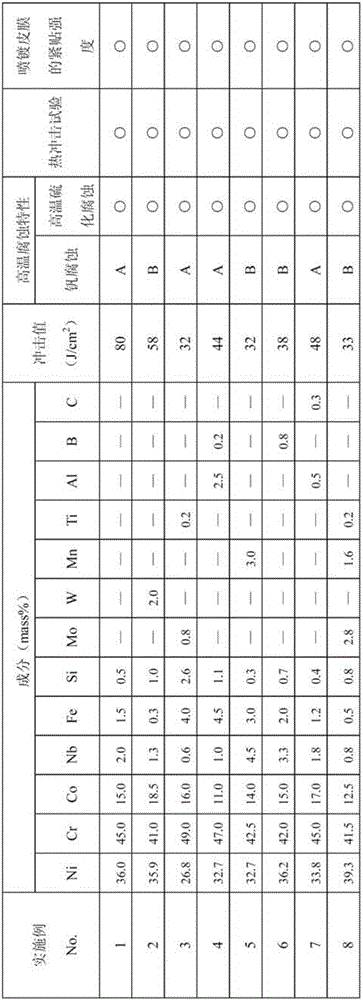

[0049] The Example alloys of the present invention and Comparative Example alloys adjusted and blended as described above were smelted, the Charpy impact value was measured by the following method, and a high temperature corrosion test was carried out. In addition, evaluation of film properties after thermal spraying using alloy powder produced by a spray method was also carried out.

[0050] (1) Charpy impact test; use an electric furnace to heat a 100g billet with the composition of each alloy to about 1600°C in an argon flow, melt it, cast it into a shell mold, and machine it into a test piece recorded in JIS Z2242:2005 (no notch). Then, using a Charpy impact tester, an impact test based on JIS Z 2242:2005 was performed to measure an impact value.

[0051] It should be noted that, in Patent Documents 9 to 15, since alloys with a Cr content of more than 60% by mass cannot be melted in an electric furnace set at about 1600° C., comparative studies were abandoned (the patents...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com