Scaffolding equipment for aggregate smokestack dismantling and dismantling method for aggregate smokestack using same equipment

A kind of scaffolding and chimney technology, which is applied to the scaffolding supported by the house structure, building types, building maintenance, etc., can solve the problems of operators losing balance, danger, and scaffolding difficulties, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

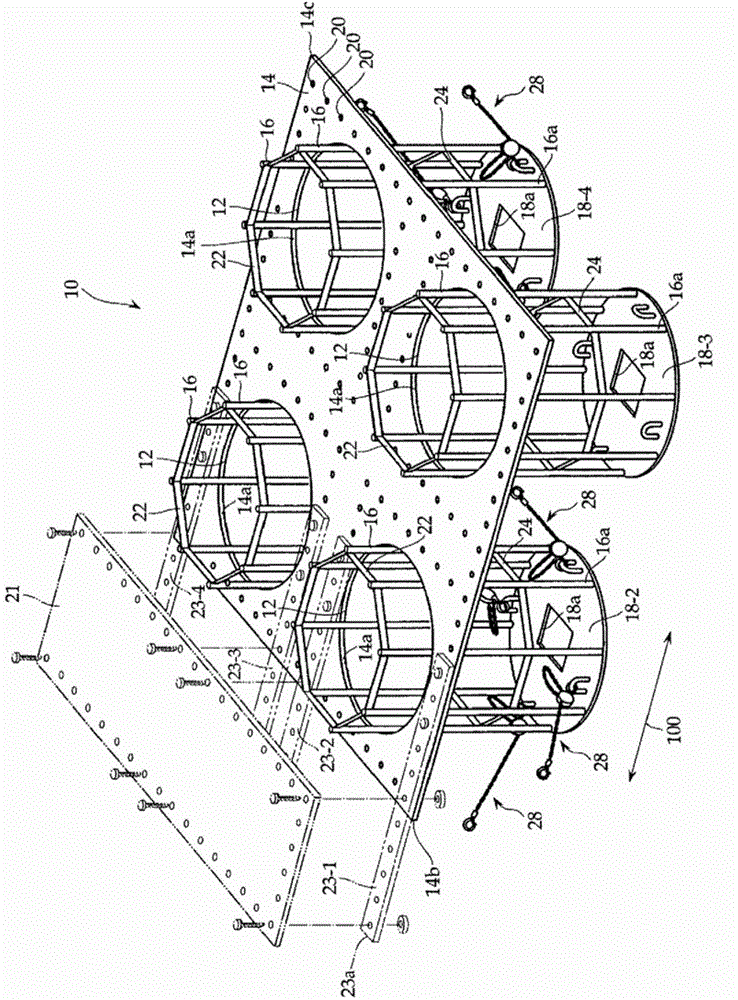

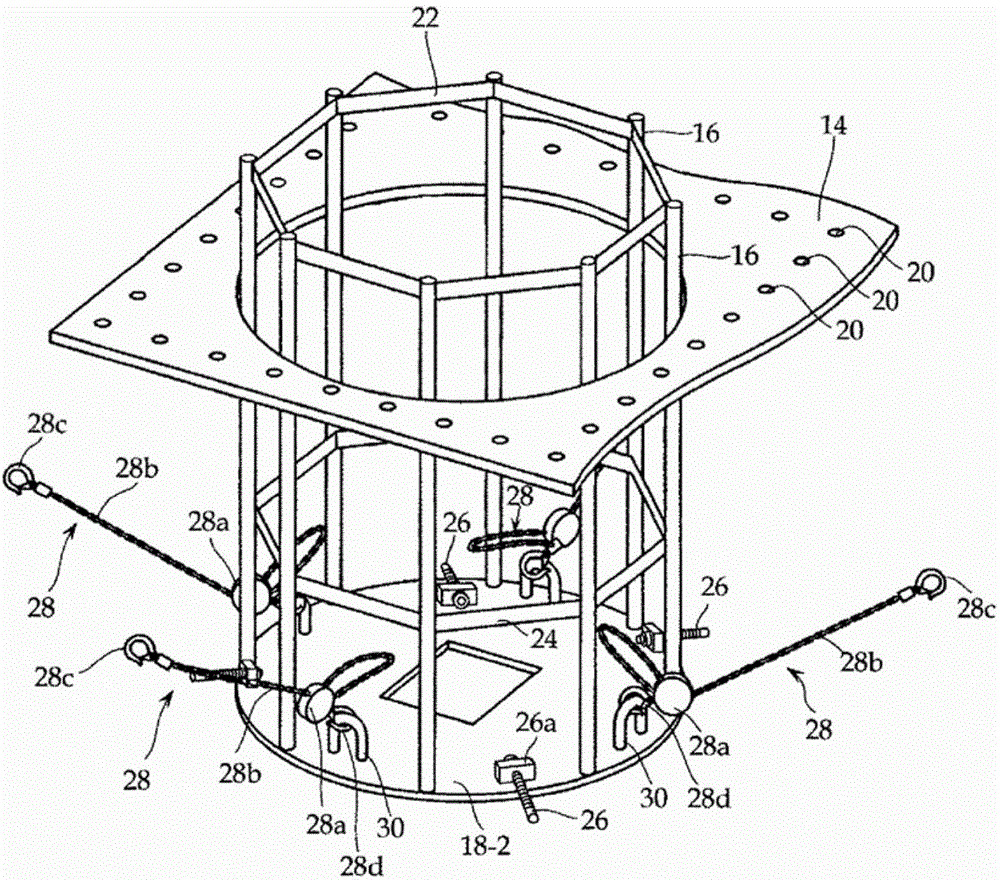

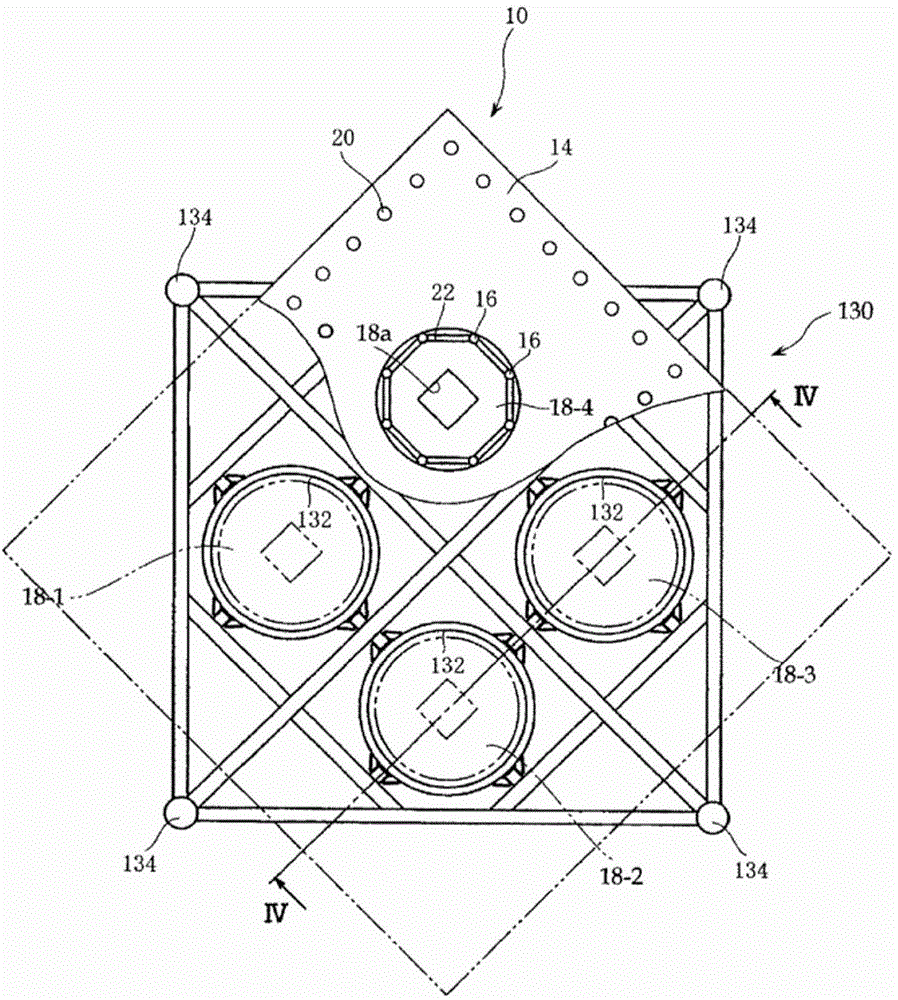

[0051] to be used for Figure 13 As shown, the case of an aggregate type chimney 130 formed by collectively arranging four single-pipe chimneys 132 vertically erected and supported by an iron tower 134 surrounding them is taken as an example. Figure 1-7 A first embodiment of the chimney removal scaffolding device of the present invention will be described.

[0052] figure 1 It is a schematic perspective view of the chimney removal scaffolding device 10 related to the first embodiment of the present invention, figure 2 It is an enlarged perspective view for explaining main parts of the chimney removal scaffolding device 10 according to this embodiment, image 3 It is a schematic plan view showing a state where the chimney removal scaffolding device 10 according to the present embodiment is placed on the upper end of each chimney pipe 132 of the collective chimney 130, Figure 4 yes image 3 Sectional view of line IV-IV, Figure 5 It is a figure for demonstrating the chi...

no. 2 Embodiment approach

[0088] to be used for Figure 14 As shown in the case where four chimneys 142 with a single-pipe structure are collectively arranged and combined in such a manner as to gradually expand from the upper part to the lower part to stand on their own, and there is no four-legged collective chimney 140 supporting the iron tower, refer to Figure 8 and 9 , and the second embodiment of the present invention will be described.

[0089] Specifically, the collective chimney 140 has four chimneys 142 arranged in a substantially rectangular shape in plan view, such as Figure 14 An upper region 140a elongated substantially vertically as shown, and a lower region 140b in which the four chimneys 142 gradually diverge radially from above to below on the lower side of the upper region 140a.

[0090] Figure 8 It is a schematic exploded perspective view of the scaffolding device 40 for removing a chimney according to the second embodiment of the present invention, Figure 9 is a schematic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com