Indexing grinding plane tooling

A technology for grinding planes and tooling, which is applied in the direction of grinding workpiece supports, etc. It can solve problems such as insufficient position accuracy, complex tooling structure design, and manufacturing difficulties, and achieve simple indexing, meet indexing requirements, and simplify the overall design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

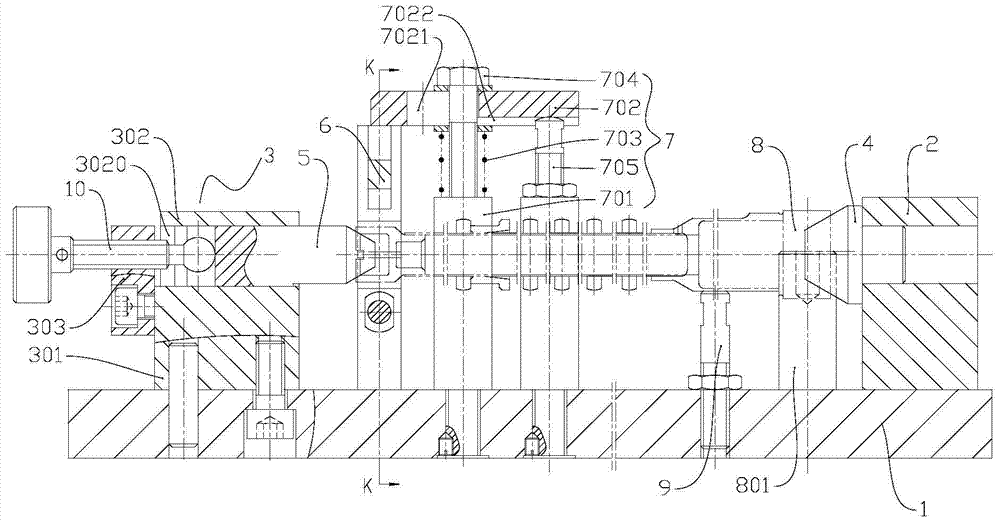

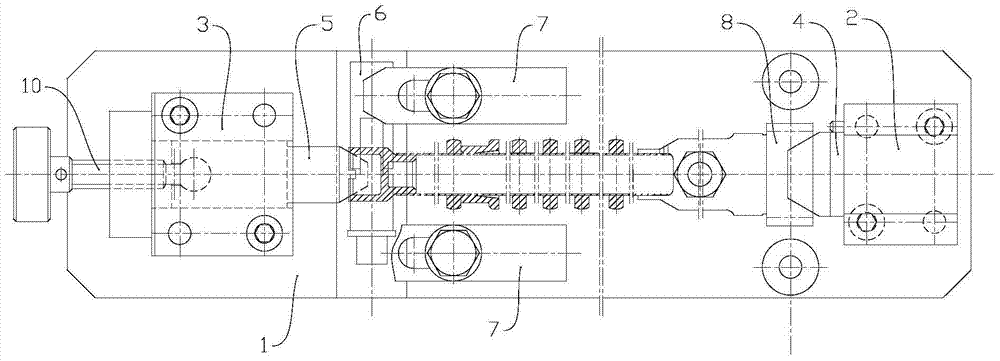

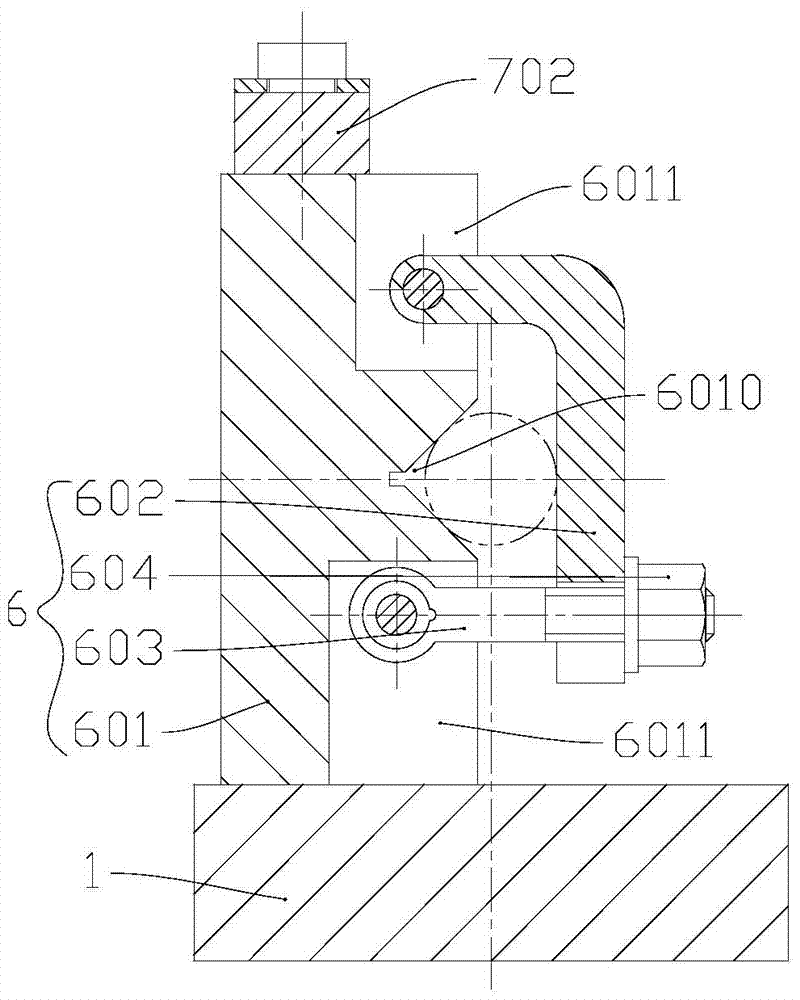

[0033] Such as Figure 1 to Figure 3As shown, the preferred embodiment of the present invention provides a kind of indexing grinding plane frock, and it comprises base plate 1, and base plate 1 is provided with relative first support 2 and second support 3, and first support 2 is provided with There is a first apex 4 for abutting against one end of the part to be processed, and a second apex 5 for abutting against the other end of the part is provided on the second support 3, and the second apex 5 is slidingly arranged in the horizontal direction; the bottom plate 1 is also provided with a positioning assembly 6 for clamping and positioning the parts. The positioning assembly 6 includes a positioning block 601. The top and bottom of the positioning block 601 are planes parallel to the bottom plate 1. Half of the height of the positioning block 601 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com