Automated manual screwdriver, accommodation seat of automated manual screwdriver and charging circuit

A screwdriver and receiving seat technology, which is applied to screwdrivers, wrenches, wrenches, etc., can solve the problems of large outer diameter of one-way valve, inconvenient carrying, loss of bit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

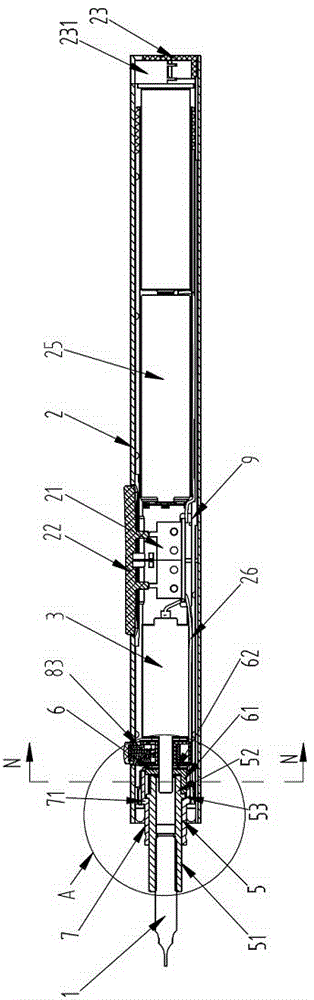

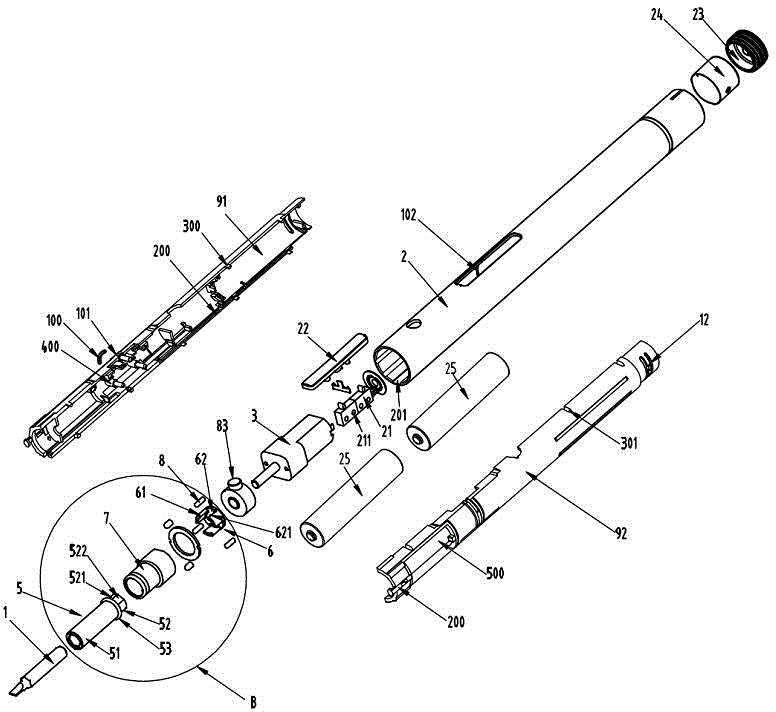

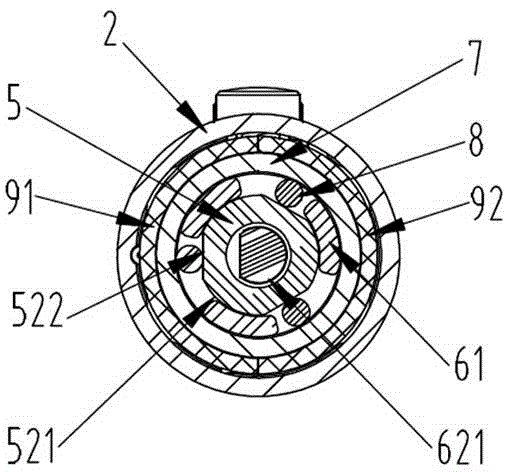

[0086] The invention provides a manual screwdriver, such as Figure 1 to Figure 5 As shown in the first embodiment shown, it includes a housing and a screwdriver bit 1 arranged in front of the housing, and a motor 3 is provided in the housing, and the motor is a geared motor. A composite mechanism 4 is provided between the screwdriver head 1 and the motor 3, and the composite mechanism enables the manual screwdriver to have a manual mode and an electric mode that can be switched between each other. Specifically, the composite mechanism 4 includes: an output shaft 5 , a support frame 6 , a bearing seat 7 , and a pin 8 .

[0087] The output shaft 5 is arranged between the screwdriver bit 1 and the motor 3. The output shaft 5 is provided with a front end 51 and a rear end 52. A fixed internal hexagon, the rear end 52 is inserted into the motor shaft of the motor 3 , and a protruding ring 53 is provided between the front end 51 and the rear end 52 . The outer profile of the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com